Preparation method for alpha-Fe2O3 photoanode applied to photoelectrolysis

A photoanode and photoelectrolysis technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of inconvenient operation, dangerous use, complex structure and other problems of precursors, and achieve simple and cheap structure, convenient operation and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

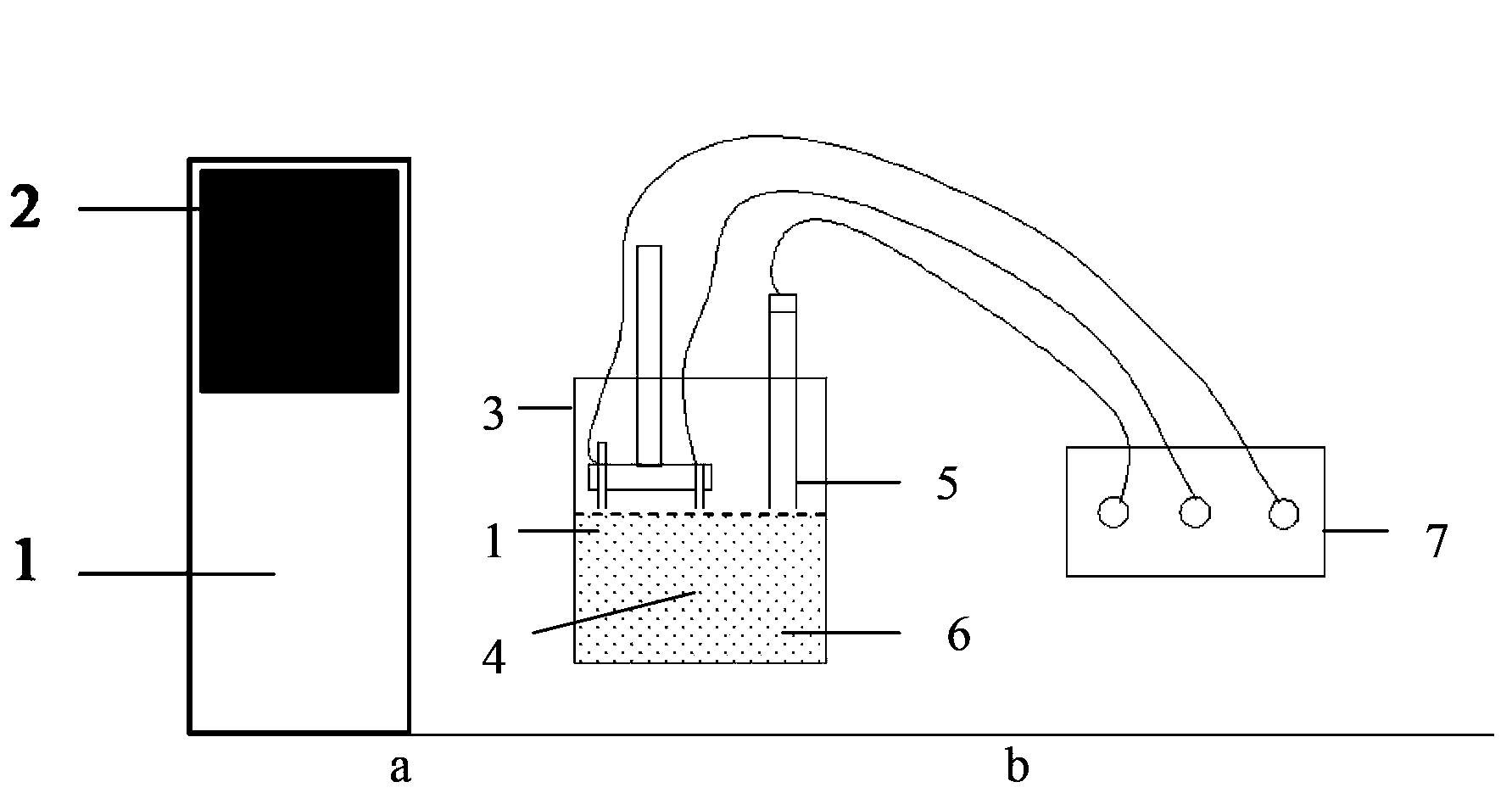

[0037] Using 0.01M FeCl 2 ·5H 2 O was used as the electrolyte solution, and 1M HCl was used to adjust the pH of the solution to 4.1. At 75 °C, α-Fe was prepared using a three-electrode system. 2 o 3 photoelectrode. Among them, FTO (conductive glass) is used as the working electrode, the Pt sheet electrode is used as the counter electrode, and the Ag / AgCl electrode (4M KCl solution) is used as the reference electrode. The optimized deposition electrode was tested under the condition of 1.2V. The deposition time is 2, 4, 8, 16min. The color of the thin film samples obtained with different deposition times varies from yellow to red. After the deposition process, the working electrode was taken out and rinsed with deionized water and then calcined in a tube furnace. In the tube furnace, the heating rate was maintained at 2°C / min from room temperature to 520°C, and then calcined at 520°C for 30min. Figure 4 α-Fe obtained after deposition and calcination 2 o 3 Digital photo...

Embodiment 2

[0039] The difference from Example 1 is that in 0.05M FeCl 2 ·5H 2 NH of O and 3M 4 Cl is used as the electrolyte, the pH value is 7.5, and the voltage is 0.3V. Among them, FTO (conductive glass) is used as the working electrode, the Pt sheet electrode is used as the counter electrode, and the Ag / AgCl electrode (4M KCl solution) is used as the reference electrode. After the deposition process is completed, calcining is carried out in the same manner as in the previous example.

Embodiment 3

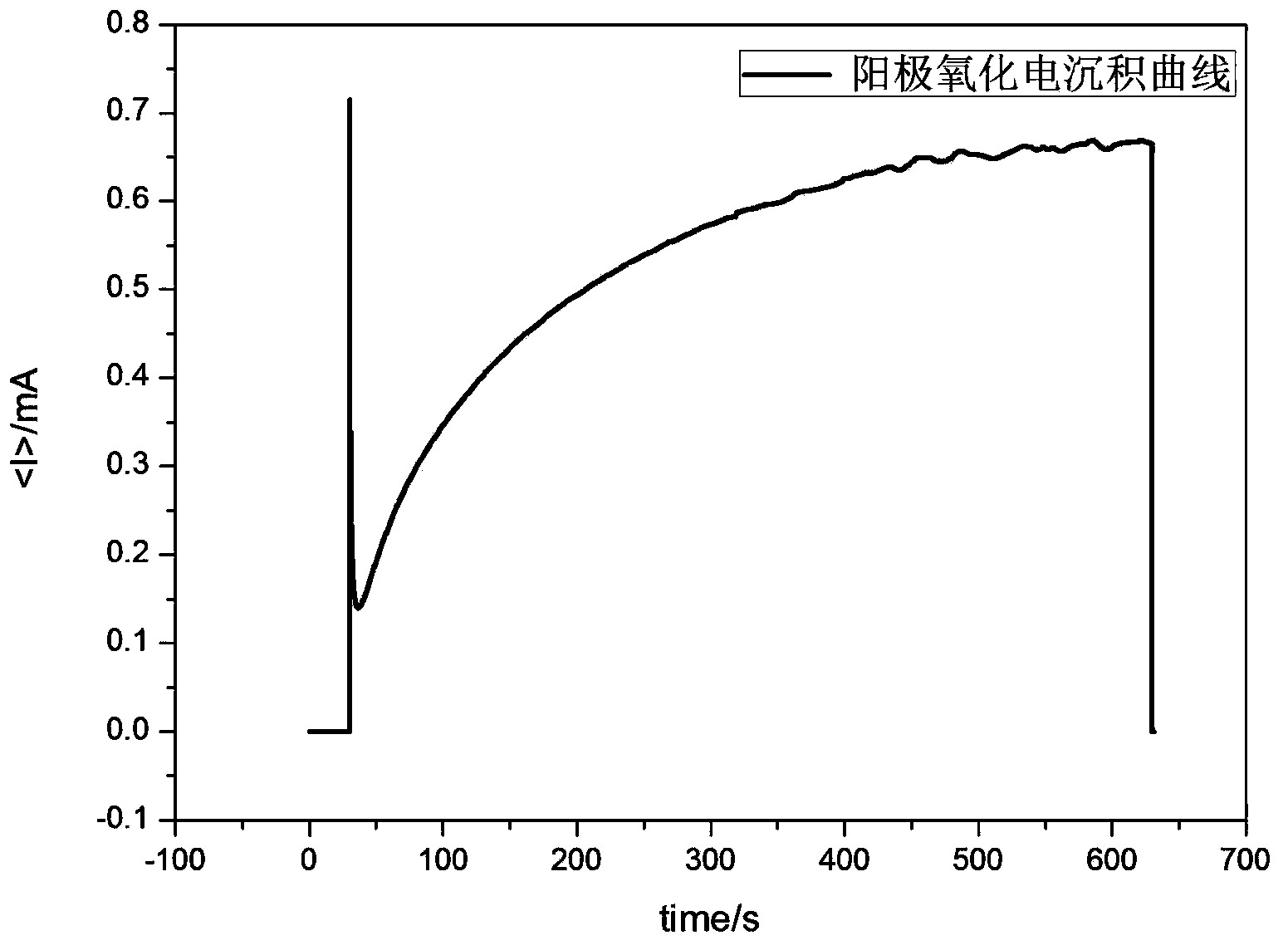

[0041] The difference from Example 1 is that the working electrode is a 2cm×5cm conductive glass, the counter electrode is a graphite plate, and Ag / AgCl (saturated KCl) is a reference electrode. Under the conditions of an applied voltage of 1.2V, pH=4.1, and 70°C under, with 0.1M FeCl 2 4H 2 O, pH=5.1 is the electrolyte solution, and the deposition time is 1min, 5min, 10min, 15min, 20min, 25min, 30min samples. After the deposition, the samples were sent into a tube furnace for high-temperature calcination at 600 °C. image 3 Anodic oxidation electrodeposition curves for different electrodeposition times. Figure 5 α-Fe 2 o 3 Photoelectric performance diagram of the photoelectrode. Image 6 Metallographic micrographs of the samples after calcination. Figure 7 is the XRD pattern of the prepared sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com