Semiconductor silicon wafer laser annealing online detection method based on photocarrier radio technology

A technology of photocarrier radiation and laser annealing, applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems affecting production efficiency, material destructiveness, affecting measurement accuracy, etc. Achieve the effect of improving measurement accuracy and sensitivity, eliminating the influence of temperature field, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

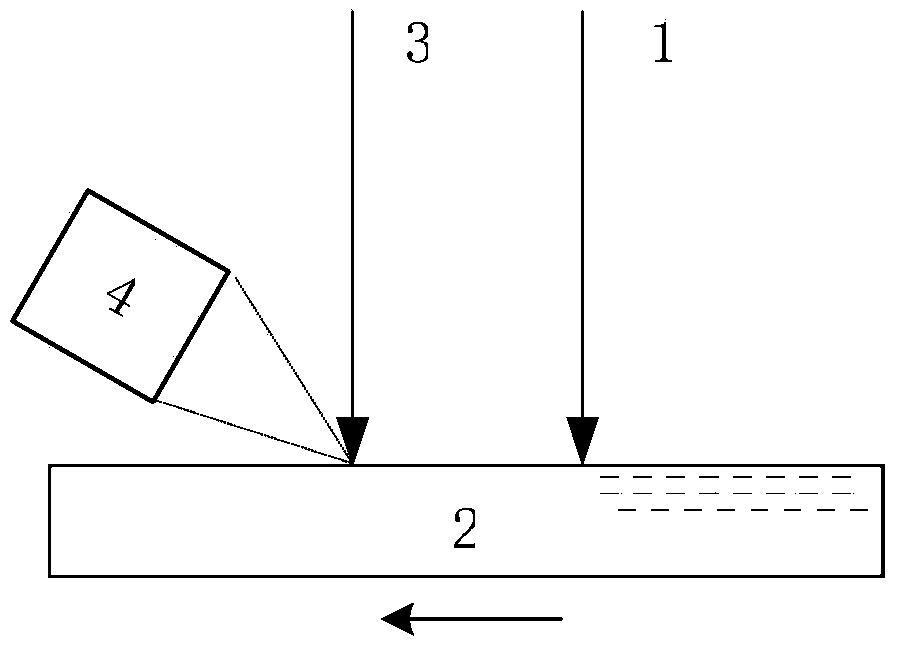

[0024] Such as figure 1 As shown, the annealing laser beam 1 output by the ArF excimer laser annealing device performs annealing treatment on the semiconductor material 2 . The excitation beam 3 in the optical detection system is output by a semiconductor laser with a center wavelength of 405nm (the photon energy generated by the excitation light is 3.06eV, which is greater than the intrinsic band gap of silicon 1.1eV), and its output power is 53mW, and passes through the function The signal generator performs periodic modulation; the photocarrier radiation signal is collected and detected by the infrared light detection device 4, which includes a long-wave pass filter for filtering the scattered light of the annealing laser beam and the excitation beam, and detects the photocarrier InP / InGaAs photomultiplier tube (PMT) detector for infrared r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap