A kind of high thermal conductivity graphene/nylon composite material and preparation method thereof

A technology of nylon composite material and high thermal conductivity graphite, which is applied in the field of high thermal conductivity graphene/nylon composite material and its preparation, can solve problems such as poor thermal conductivity, and achieve the effect of improved compatibility and strong interface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

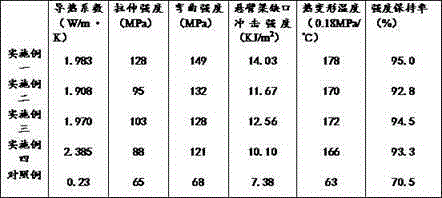

Examples

Embodiment 1

[0028] High thermal conductivity graphene / nylon composite material of the present invention, its component is by mass fraction, chooses 40 parts of nylon, 4 parts of expandable graphite, 0.8 part of amphiphilic pyrene graft, 10 parts of highly oriented silicon nitride fiber, 10 parts of carbon fiber, 7 parts of boron nitride, 0.1 part of high temperature resistant agent, 0.3 part of antioxidant, 1 part of anti-hydrolysis agent, 4 parts of toughening agent, first place expandable graphite and amphiphilic pyrene grafts together Ultrasonic oscillation for 3 hours in a mixed solvent with a certain ratio of H2O / MeOH=6 / 4, and then centrifuged at 1200rpm for 16min, the supernatant is the dispersed graphene solution, and the supernatant was placed for 70 ℃ oven drying 15h to obtain dry powdery graphene. Then the prepared graphene powder and nylon particles were mixed evenly, and ground in a three-roll mill for 10 min, and set aside. Finally, the uniformly mixed nylon / graphene particl...

Embodiment 2

[0030] High thermal conductivity graphene / nylon composite material of the present invention, its component selects 40 parts of nylons, 5 parts of expandable graphites, 1 part of amphiphilic pyrene grafts, 15 parts of highly oriented silicon nitride fibers by mass parts, 5 parts of carbon fiber, 5 parts of boron nitride, 0.3 part of high temperature resistant agent, 0.2 part of antioxidant, 1 part of anti-hydrolysis agent, 6 parts of toughening agent, first place the expandable graphite and the amphiphilic pyrene graft on the Ultrasonic oscillation in a mixed solvent with a certain ratio of H2O / MeOH=7 / 3 was carried out for 3 hours, and then centrifuged at 1300 rpm for 20 minutes. The supernatant was the dispersed graphene solution, and the supernatant was placed for 90 ℃ oven drying 18h to obtain dry powdered graphene. Then the prepared graphene powder and nylon particles were mixed evenly, and ground in a three-roller mill for 12 min, and set aside. Finally, mix the uniformly...

Embodiment 3

[0032]High thermal conductivity graphene / nylon composite material of the present invention, its component selects 50 parts of nylons, 5 parts of expandable graphites, 1.2 parts of amphiphilic pyrene grafts, 12 parts of highly oriented silicon nitride fibers in parts by mass, 8 parts of carbon fiber, 8 parts of boron nitride, 0.5 part of high temperature resistant agent, 0.4 part of antioxidant, 1.2 parts of anti-hydrolysis agent, 8 parts of toughening agent, first place the expandable graphite and the amphiphilic pyrene graft on the Ultrasonic oscillation in a mixed solvent with a certain ratio of H2O / MeOH=7 / 5 was carried out for 3 hours, and then centrifuged at 1400rpm for 20min. The supernatant was the dispersed graphene solution. Place the supernatant for 100 ℃ oven drying 18h to obtain dry powdered graphene. Then the prepared graphene powder and nylon particles were mixed evenly, and ground for 16 min in a three-roller mill, and set aside. Finally, mix the uniformly mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com