Metal-phase carrier loaded catalyst as well as preparation method and application

A technology of carrier loading and metal phase, which is applied in the field of catalysis, can solve the problems of pollution in the preparation process, insufficient catalytic activity, high chemical activity, etc., and achieve the effect of easy availability of raw materials, meeting the requirements of catalytic performance, and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

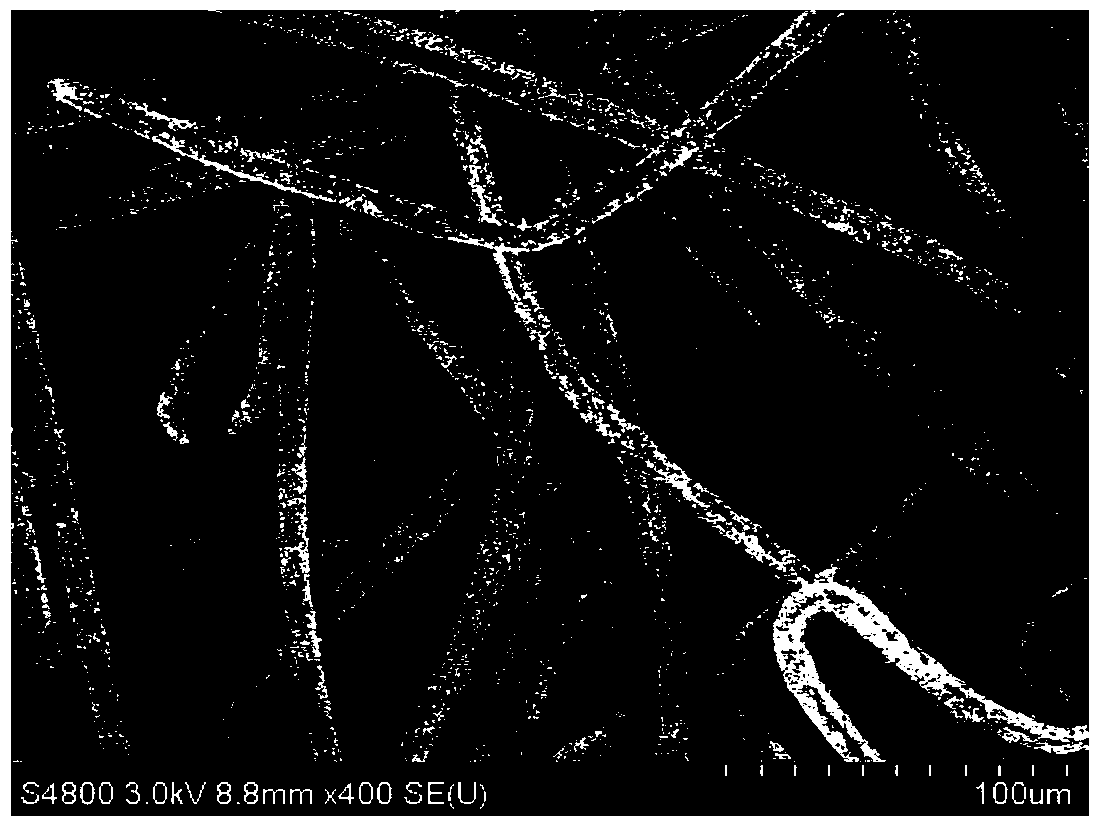

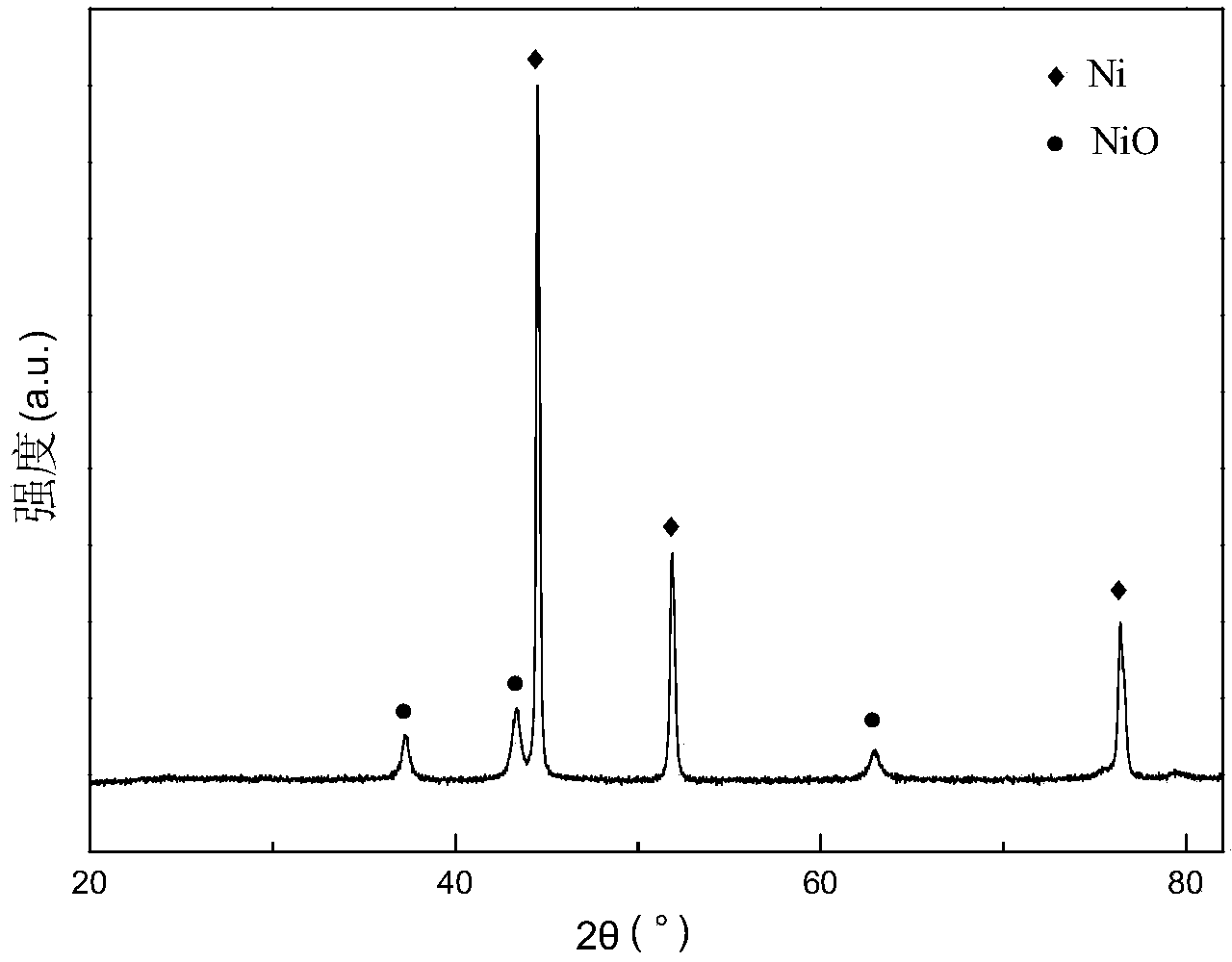

[0035] This example provides the preparation of a nickel oxide-alumina catalyst supported by sintered nickel metal fiber carrier.

[0036] ① Weigh 15 grams of nickel metal fibers with a diameter of 8 microns and a length of 2 to 5 mm, 2.5 grams of cellulose fibers with a length of 0.1 to 1 mm and 1.5 liters of water, and add them to the mixer, fully stir to form a uniformly dispersed fiber slurry and then transfer In the paper machine, add water to 8.5 liters, stir, drain and shape; after drying, bake at 500°C in air for 1 hour; then sinter at 950°C in hydrogen for 1 hour, and the thickness of the product is controlled by pressing At 1 mm, a sintered metal nickel fiber support is obtained, expressed as 8-Ni-SMF;

[0037] ② Cut the sintered metal nickel fiber carrier obtained in step ① into discs with a diameter of 16 mm, weigh 5 grams and place them in a 50 ml beaker. At room temperature, pipette the suspension containing 0.1 g of aluminum powder with a particle size of 1 to ...

Embodiment 2

[0051] This example provides the preparation of a nickel oxide-alumina catalyst supported by sintered red copper metal fiber carrier.

[0052] ① Weigh 15 grams of copper metal fibers with a diameter of 8 microns and a length of 2 to 5 mm, 2.5 grams of cellulose fibers with a length of 0.1 to 1 mm, and 1.5 liters of water, and add them to the mixer, fully stir to form a uniformly dispersed fiber slurry and then transfer In the paper machine, add water to 8.5 liters, stir, drain and shape; after drying, bake in air at 250°C for 1 hour; then sinter in hydrogen at 900°C for 1 hour to obtain a sintered metal copper fiber carrier. Expressed as 8-Cu-SMF;

[0053] ② Cut the sintered metal red copper fiber carrier obtained in step ① into discs with a diameter of 16 mm, weigh 5 grams and place them in a 50 ml beaker. At room temperature, pipette an equal volume of suspension containing 0.4 grams of aluminum powder with a particle size of 1 to 3 microns to impregnate the metal phase car...

Embodiment 3

[0060] This example provides the preparation of an iron oxide-alumina catalyst supported on a red copper fiber carrier.

[0061]① Weigh 15 grams of copper metal fiber (expressed as Cu-fiber) with a diameter of 30 microns and a length of 5-10 mm, and at room temperature, pipette the suspension containing 0.075 grams of aluminum powder with a particle size of 1-3 microns. After impregnating the metal phase carrier with equal volume of liquid and drying to disperse the aluminum powder particles on the surface of the metal phase carrier, the solid-solid alloying reaction between the aluminum powder particles and the surface layer of the metal phase carrier was carried out at 600°C in a high-purity protective atmosphere for 2 hours. Obtain a metal phase carrier with surface alloying;

[0062] ② The product obtained in step ① is subjected to an aluminum extraction treatment with a 5% hydrochloric acid aqueous solution at room temperature to 60° C. for 1 hour, rinsed with distilled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com