Water-based externally coated metal printing whitewash and preparation method thereof

A technology of printing and iron white, applied in the field of iron white printing, can solve the problems of construction personnel's health injury and environmental pollution, and achieve the effects of less air pollution, lower production costs, and less toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

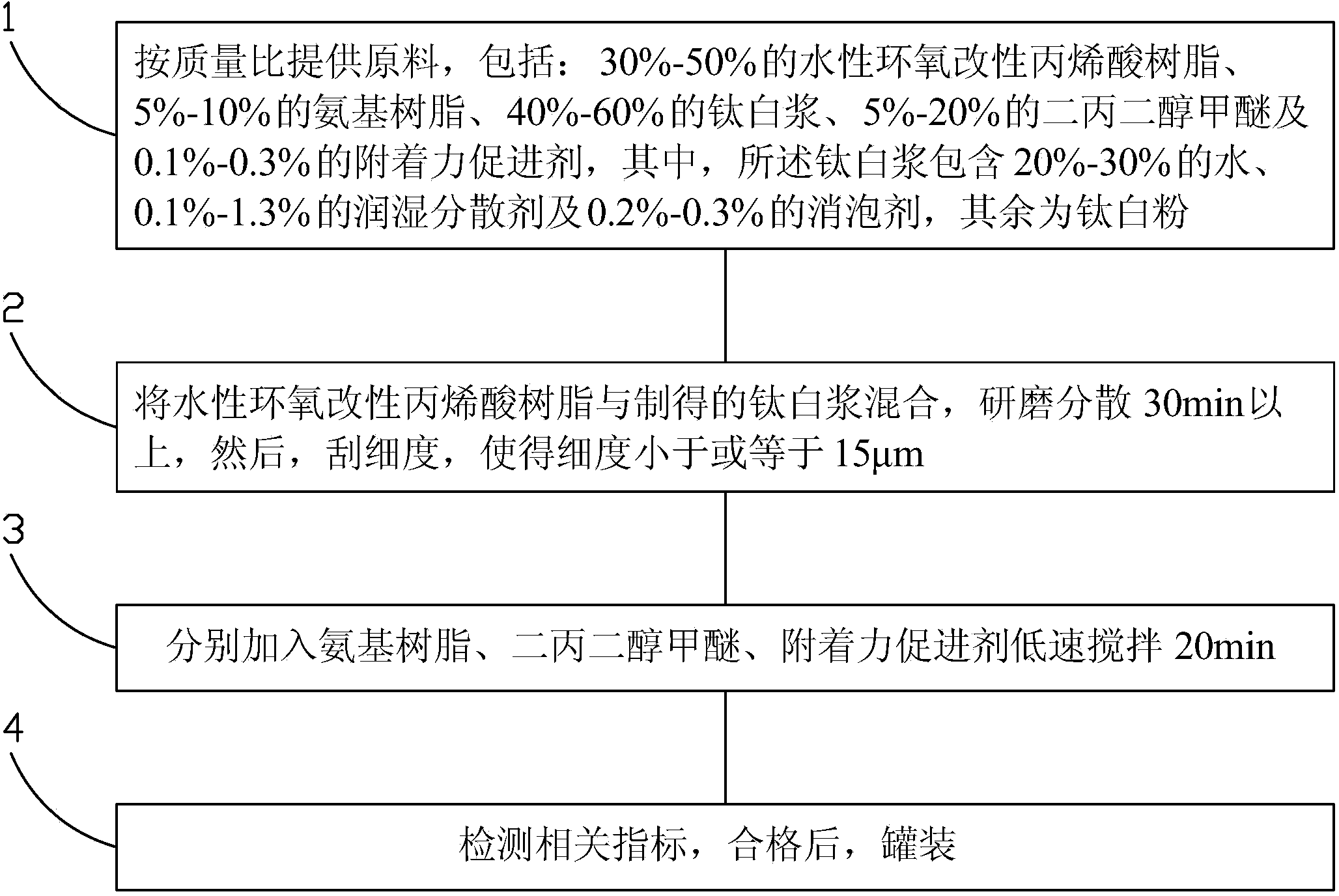

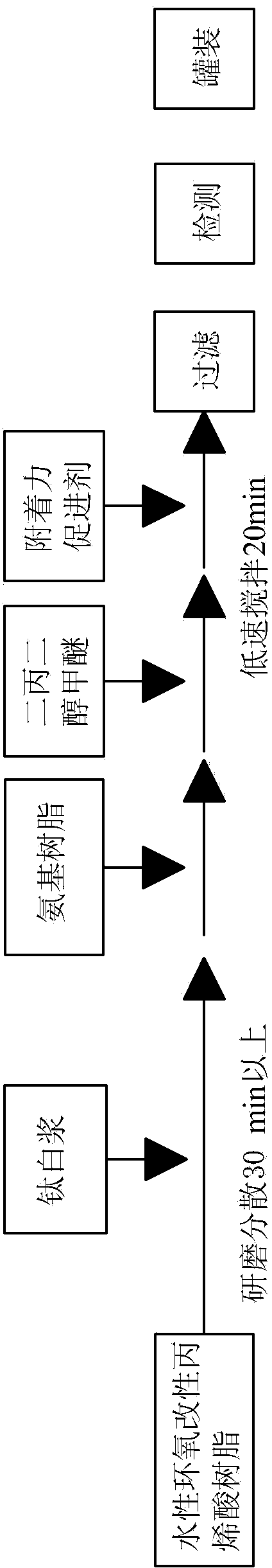

[0024] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

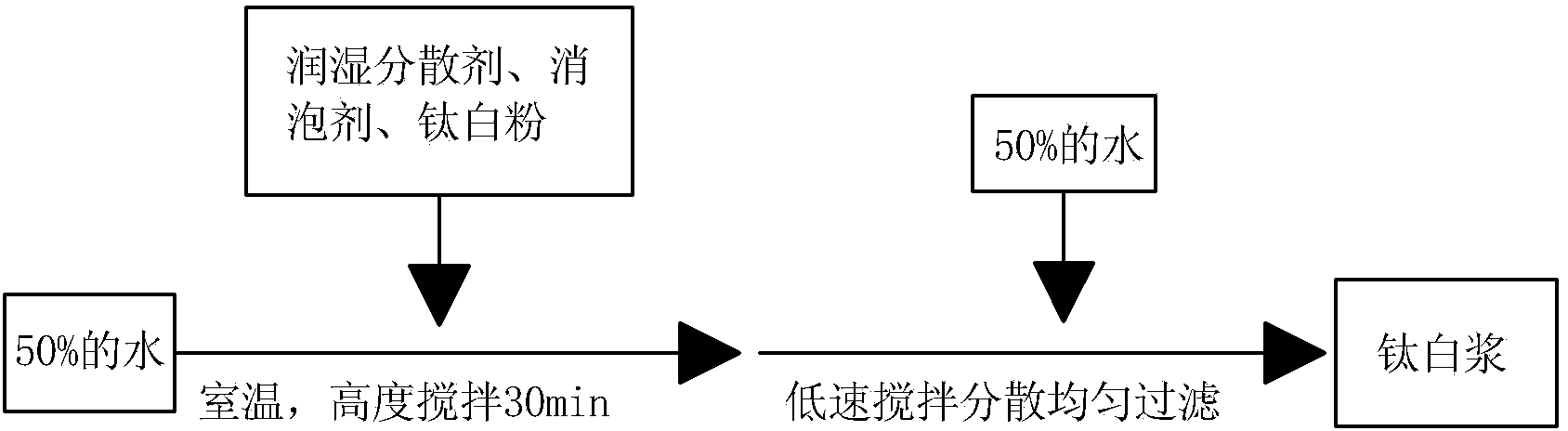

[0025] The invention provides a water-based external printing iron white coating, which comprises: 30%-50% of water-based epoxy-modified acrylic resin, 5%-10% of amino resin, and 40%-60% of titanium White pulp, 5%-20% dipropylene glycol methyl ether and 0.1%-0.3% adhesion promoter, wherein, the titanium white pulp contains 20%-30% water, 0.1%-1.3% wetting and dispersing Agent and 0.2%-0.3% defoamer, the rest is titanium dioxide. Water-based epoxy-modified acrylic resin and amino resin are cross-linked and solidified, and certain additives and white slurry are added to obtain the water-based external printing iron white coating with good adhesion, strength and process resistance of the present invention, reducing the At the same time, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com