Immobilized cutinase, preparation method and application of removing phthalates in water

A technology of phthalic acid and cutinase, applied in the direction of immobilization on or in inorganic carriers, chemical instruments and methods, water pollutants, etc., can solve the problems affecting the application of immobilized enzymes, general biocompatibility, General problems such as adsorption stability, to achieve the effect of eliminating tissue defects, good adsorption stability, and high activity recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

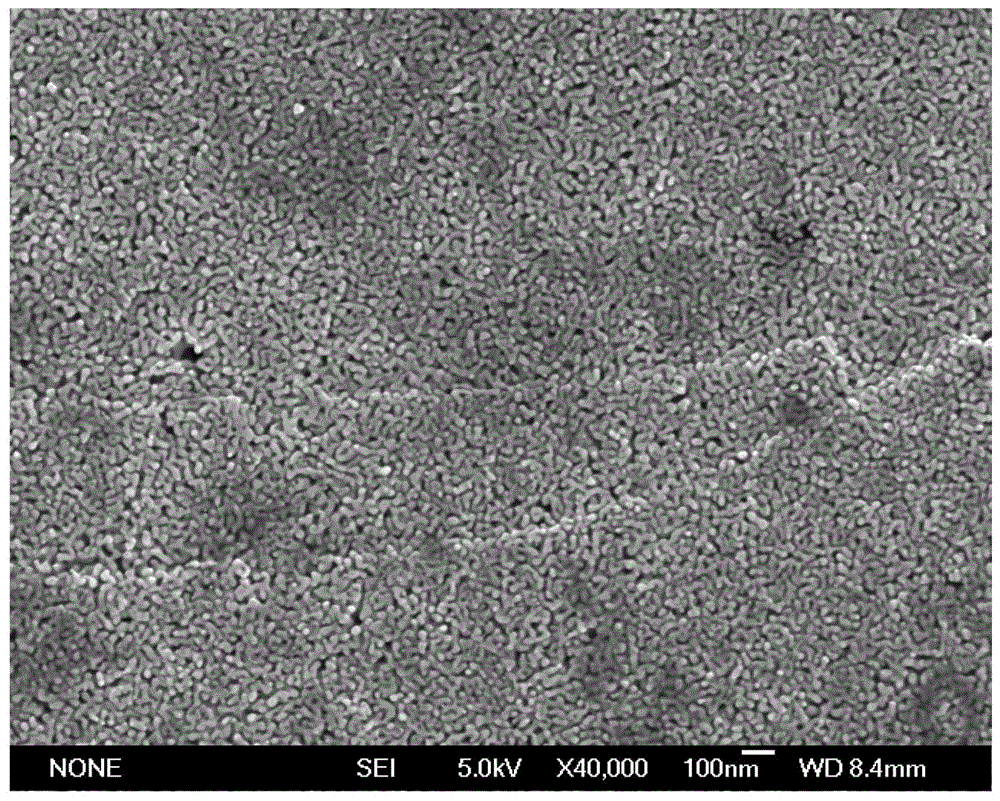

Embodiment 1

[0033] The immobilized cutinase uses a porous gold nanometer material as a carrier, and the cutinase is fixed on the porous gold nanometer material through physical adsorption to obtain the immobilized cutinase. The steps are as follows: 10 mg of porous gold nanomaterials are added to the cutinase solution, the cutinase solution is prepared from cutinase and Tris-HCl buffer (concentration is 20 mM, pH value is 8.0), the cutinase in the cutinase solution The concentration is 0.8 mg / mL, the mass of cutinase in the cutinase solution is 4 mg, shake and adsorb at 120 rpm at 50 ° C for 6 h, then wash several times with Tris-HCl buffer solution with a pH value of 8.0, and take out the sheet-shaped porous gold The nanometer material is freeze-dried at -40° C. to obtain immobilized cutinase. The cutinase adsorption capacity of the porous gold nanomaterial is 39.2mg / g, and the pore diameter of the porous gold nanomaterial is 40-50nm. The recovery rate of the enzyme activity of the immo...

Embodiment 2

[0040]The immobilized cutinase uses a porous gold nanometer material as a carrier, and the cutinase is fixed on the porous gold nanometer material through physical adsorption to obtain the immobilized cutinase. The steps are: 10 mg of porous gold nanomaterials are added to the cutinase solution, the cutinase solution is prepared from cutinase and phosphate buffer, the concentration of cutinase in the cutinase solution is 0.2 mg / mL, and the cutinase solution The mass of cutinase in the medium is 6 mg, the pH value of the cutinase solution is 9.0, oscillating and adsorbing at 150 rpm at 45 ° C for 4 h, and then washed several times with Tris-HCl buffer solution with a pH value of 8.0, and the sheet-shaped porous gold nanomaterial is taken out, Freeze and vacuum-dry at -40°C to obtain immobilized cutinase. The cutinase adsorption capacity of the porous gold nanomaterial is 36.5mg / g, the pore diameter of the porous gold nanomaterial is 40-50nm, the enzyme activity recovery rate of...

Embodiment 3

[0045] Preparation of immobilized cutinase under different oscillation adsorption time conditions

[0046] Take 10 mg of the porous gold nanomaterial prepared in Example 1 as a carrier, add 10 mL of Tris-HCl buffer containing 4 mg of cutinase (concentration is 20 mM, pH value is 8.0), and absorb at 50 ° C at a speed of 150 rpm for 30 ~360min, after the immobilization is completed, wash several times with Tris-HCl buffer solution with a pH value of 8.0, take out the flake-shaped porous gold nanomaterial, and freeze and vacuum-dry it at -40°C to obtain the immobilized cutinase.

[0047] The amount of cutinase in the buffer solution before fixation and the remaining cutinase amount in the buffer solution after fixation were respectively measured by the Lowry method, and the cutinase adsorbed by the unit carrier in different time was calculated, and the results were shown in Table 1; from the data analysis in Table 1, it can be seen that the appropriate The range of vibration adso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com