Preparation method of high-entropy AlCoNiCrFeMo alloy coating

An alloy coating and high-entropy technology, applied in metal material coating process, coating, etc., can solve the problems of expensive equipment, high energy consumption, insufficient bonding strength, etc., achieve simple and easy process cost, improve production efficiency, and high The effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

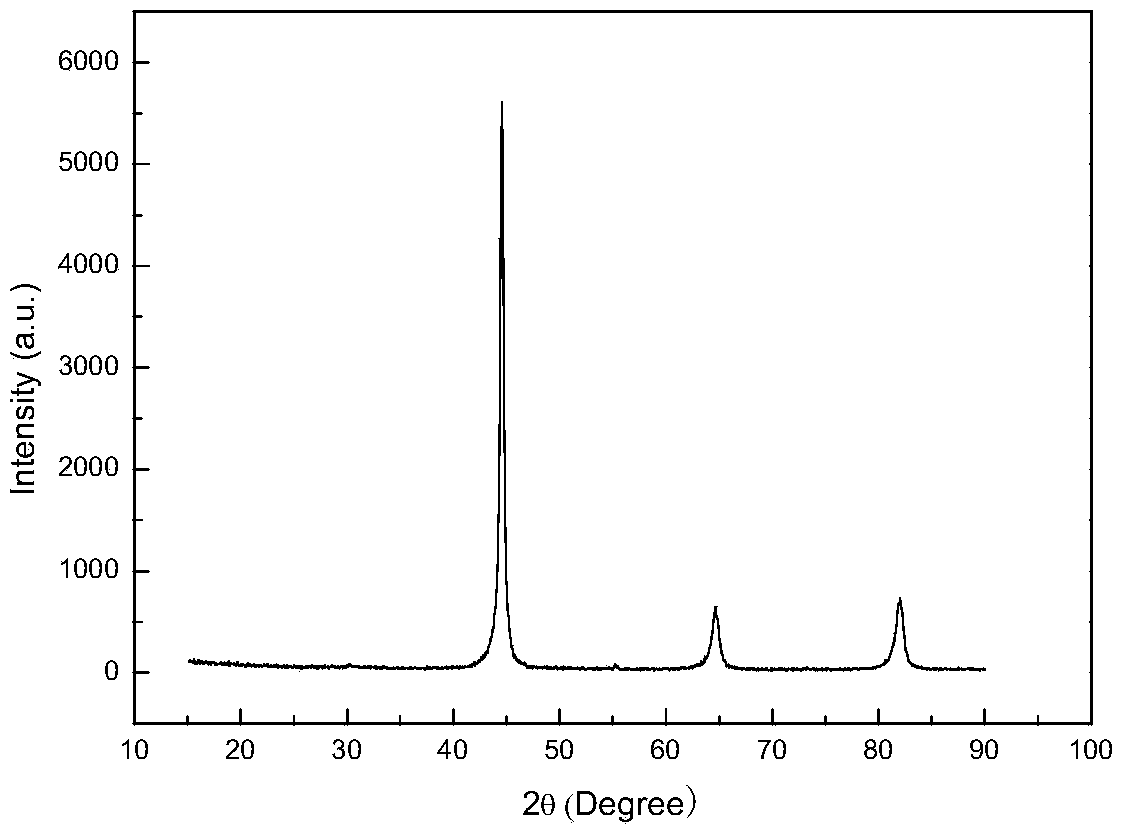

Image

Examples

Embodiment 1

[0022] A high-entropy AlCoNiCrFeMo alloy coating composition includes: 100% Al, 100% Co, 100% Cr, 100% Fe, 100% Ni, 50% Cu, 10% C (at.%).

[0023] The preparation method of described high-entropy AlCoNiCrFeMo alloy coating, concrete steps are as follows:

[0024] (1) Alloy ratio: Alloy, Co, Cr, Fe, Ni and Mo with a purity of not less than 99.9 wt% were used as the elemental raw materials used in the test. Remove the oxide film on the surface of Al, Co, Cr, Fe, Ni and Mo with a steel brush, utilize a precision electronic balance to weigh the quality of the above-mentioned elemental raw materials, the total mass of the above-mentioned elemental raw materials is 120 grams. Then use petroleum ether and absolute ethanol to ultrasonically clean the above-mentioned simple raw materials, and finally mix the above-mentioned simple raw materials into a tungsten magnetron electric arc furnace.

[0025] (2) Master alloy smelting: Vacuumize the working chamber of the tungsten magnetron el...

Embodiment 2

[0032] A high entropy AlCoNiCrFeMo alloy coating composition includes: 100% Al, 100% Co, 100% Cr, 100% Fe, 100% Ni, 50% Cu, 10% C(at.%).

[0033] The preparation method of described high-entropy AlCoNiCrFeMo alloy coating, concrete steps are as follows:

[0034](1) Alloy ratio: Alloy, Co, Cr, Fe, Ni and Mo with a purity of not less than 99.9 wt% were used as the elemental raw materials used in the test. Remove the oxide film on the surface of Al, Co, Cr, Fe, Ni and Mo with a steel brush, utilize a precision electronic balance to weigh the quality of the above-mentioned elemental raw materials, the total mass of the above-mentioned elemental raw materials is 120 grams. Then use petroleum ether and absolute ethanol to ultrasonically clean the above-mentioned simple raw materials, and finally mix the above-mentioned simple raw materials into a tungsten magnetron electric arc furnace.

[0035] (2) Master alloy smelting: Vacuumize the working chamber of the tungsten magnetron elec...

Embodiment 3

[0041] A high-entropy AlCoNiCrFeMo alloy coating composition includes: 100% Al, 100% Co, 100% Cr, 100% Fe, 100% Ni, 50% Cu, 10% C (at.%).

[0042] The preparation method of described high-entropy AlCoNiCrFeMo alloy coating, concrete steps are as follows:

[0043] (1) Alloy ratio: Alloy, Co, Cr, Fe, Ni and Mo with a purity of not less than 99.9 wt% were used as the elemental raw materials used in the test. Remove the oxide film on the surface of Al, Co, Cr, Fe, Ni and Mo with a steel brush, utilize a precision electronic balance to weigh the quality of the above-mentioned elemental raw materials, the total mass of the above-mentioned elemental raw materials is 120 grams. Then use petroleum ether and absolute ethanol to ultrasonically clean the above-mentioned simple raw materials, and finally mix the above-mentioned simple raw materials into a tungsten magnetron electric arc furnace.

[0044] (2) Master alloy smelting: Vacuumize the working chamber of the tungsten magnetron el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com