Radio-frequency power LDMOS device and manufacturing method thereof

A technology of radio frequency power and devices, which is applied in the field of radio frequency power LDMOS devices and its preparation, can solve the problems of reducing device power gain, etc., and achieve the effects of reducing parasitic gate-drain capacitance, good DC and RF characteristics, and improving DC characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

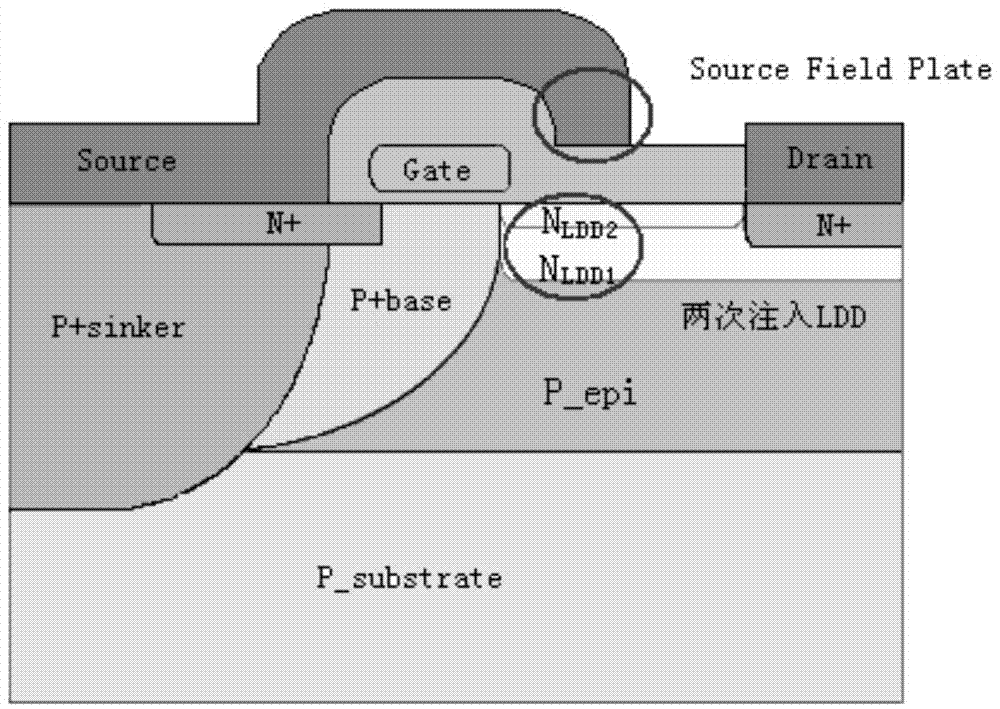

[0054] Channel region optimization design

[0055] 1. Gate oxide optimization design

[0056] LDMOS devices work in the saturation region. Transconductance is an important parameter to measure the amplification capability of the device. Its calculation formula is:

[0057] g m = ∂ I DS ∂ V GS | V BS , V DS Cons tan t = μ n W L C ox ( V GS - V T ) ...

Embodiment 2

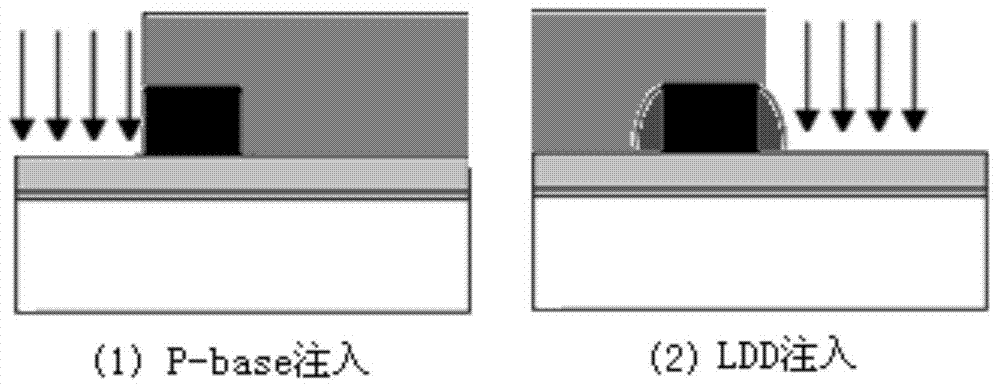

[0073] Drift zone design optimization

[0074] The research of the present invention finds that the requirements of the withstand voltage and on-resistance of the LDMOS device on the concentration and thickness of the drift region are contradictory. High breakdown voltage requires light doping, deep diffusion, and long drift region, while low on-resistance requires heavy doping, shallow diffusion, and short drift region. The LDMOS device in the present invention focuses on optimizing the doping implantation in the drift region on the premise that the design of the drift length can meet the requirement of the breakdown voltage. The drift region of the LDMOS of the present invention is implanted twice to form a deep junction LDD1 region and a heavily doped surface LDD2 region, and the same mask is used for the two implantations. The design process of the LDMOS drift region will be discussed in detail below.

[0075] 1. Design of drift zone length

[0076] The length of the dri...

Embodiment 3

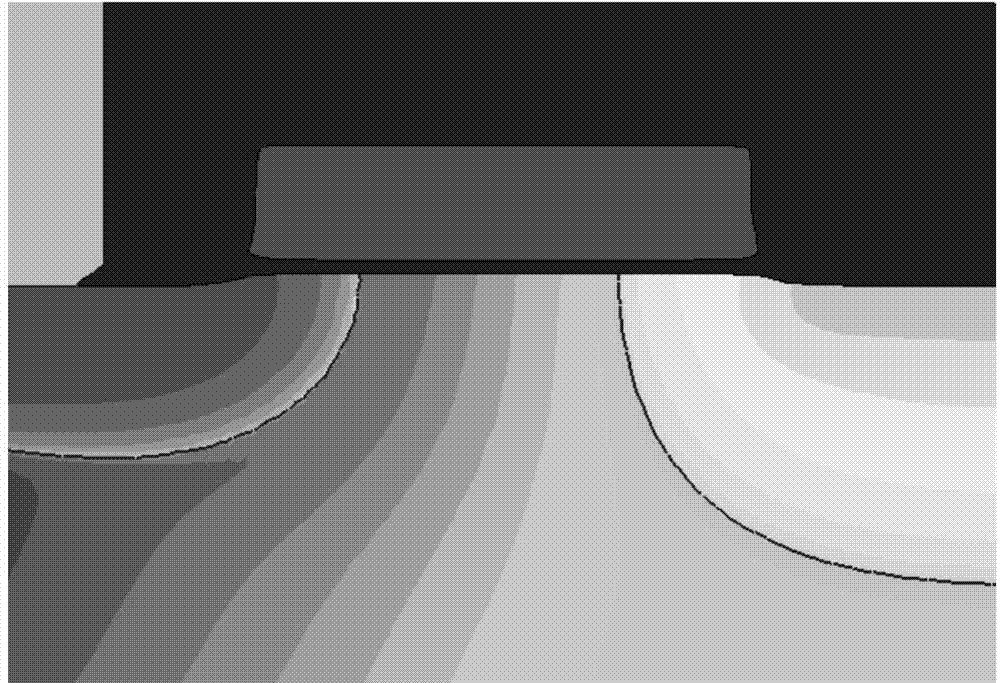

[0087] SFP Field Board Optimization

[0088] The SFP plate is formed by elongating the source plate above the drift region to form a field plate when the metal is etched to form the source and drain metal contacts. When an SPF field plate is added above the drift region of the LDMOS device, since the field plate is connected to the source with a potential of 0, it can be found that the electric field lines in the drift region close to the drain region will shift towards the drain direction under the action of the field plate, so the SFP The field plate has the effect of optimizing the electric field in the drift region close to the gate region. Through the study of the drift region doping implantation in Example 2, it was found that when the LDD2 region was implanted with too high an impurity concentration, the breakdown occurred in the region of the drift region close to the gate, and the research of the present invention surprisingly found that, The SFP field plate can be u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com