A kind of preparation method of yogurt

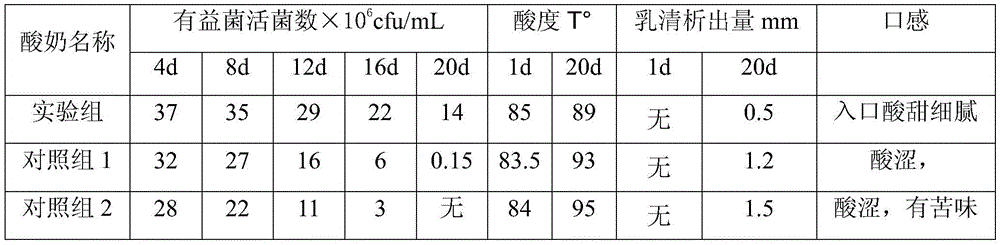

A technology for yogurt and milk volume, applied in milk preparations, dairy products, applications, etc., can solve the problems of insufficient nutritional value and health care function of yogurt, unremarkable typical flavor of fermented milk, long yogurt solidification time, etc., and achieve the best taste Small changes in the amount of whey precipitation, shorten the coagulation time, and reduce the effect of whey separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The specific breeding process of described Lactobacillus plantarum is as follows:

[0036] 1. Diethyl Sulfate (DES) Mutagenesis Breeding

[0037] (1) Take a ring of Lactobacillus plantarum on the slant of the test tube on the ultra-clean bench, put it into a 250 mL conical flask containing 50 mL of liquid MRS xylan medium, and cultivate it at 200 rpm and 40 °C for about 12 hours, so that the bacteria are in the opposite direction. number of pre-growth stages.

[0038] (2) Take 5 mL of bacterial liquid, centrifuge at 5000 rpm for 10 min to collect bacterial cells, and wash twice with normal saline.

[0039] (3) Dilute to 10 with pH 7.0 phosphate buffer 7 cells / mL bacterial suspension.

[0040] (4) Take 32 mL of potassium phosphate buffer at pH 7.0, 8 mL of bacterial suspension, and 0.4 mL of DES, and mix them thoroughly in a 150 mL Erlenmeyer flask that was placed in the rotor beforehand, so that the final concentration of DES is 1% (v / v).

[0041] (5) React at 150 r...

Embodiment 2

[0057] A preparation method of yogurt, comprising the steps:

[0058] Raw material processing: acceptance, sterilization, storage, standardization, batching, degassing and homogenization of raw milk;

[0059] Secondary sterilization: After homogenization, the material is sterilized through a heat exchanger, and the conditions are 95°C, 300s;

[0060] Cooling and inoculation: The sterilized material is cooled to 44°C, and the mixed working fermentation inoculum is added in an amount of 3% of the raw milk.

[0061] The mixed working starter is composed of Lactobacillus plantarum, Lactobacillus bulgaricus and Bifidobacterium animalis;

[0062] The mass ratio of the Lactobacillus plantarum, Lactobacillus bulgaricus and Bifidobacterium animalis is 1:0.2:0.2;

[0063] Fermentation: After the inoculation work is completed, the stirring is started, and the stirring is stopped after 15 minutes. The temperature of the fermenter is kept at 43 ° C, and the fermentation is 3 hours. When ...

Embodiment 3

[0066] A preparation method of yogurt, comprising the steps:

[0067] Raw material processing: acceptance, sterilization, storage, standardization, batching, degassing and homogenization of raw milk;

[0068] Secondary sterilization: After homogenization, the material is sterilized through a heat exchanger, and the conditions are 95°C, 300s;

[0069] Cooling and inoculation: The sterilized material is cooled to 44°C, and the mixed working fermentation bacterial agent is added, and the amount added is 4% of the raw milk.

[0070] The mixed working starter is composed of Lactobacillus plantarum, Lactobacillus bulgaricus and Bifidobacterium animalis;

[0071] The mass ratio of the Lactobacillus plantarum, Lactobacillus bulgaricus and Bifidobacterium animalis is 1:0.4:0.3;

[0072] Fermentation: After the inoculation work is completed, the stirring is started, and the stirring is stopped after 15 minutes. The temperature of the fermenter is kept at 45 ° C, and the fermentation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com