Graphene preparation method

A graphene and graphene dispersion technology, applied in graphene, nano-carbon and other directions, can solve the problems of mismatched Hansen solubility parameters, high boiling point of organic solvents, inability to achieve peeling, etc., and achieve convenient production and low oxygen content. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 1g of graphite powder to 120mL of water, the size of the graphite powder is 100 microns, place in a closed reaction kettle, stir at 600rpm, and heat to 240°C, keep for 5 hours for hydrothermal exfoliation. After cooling, the solution was centrifuged at a speed of 1000 rpm for 60 min, and the upper layer liquid after centrifugation was taken with a pipette to obtain a graphene dispersion uniformly dispersed in a mixed solvent. The graphene dispersion was subjected to high-speed centrifugation at 8000 rpm for 15 minutes to obtain the lower solid which was graphene. The weighed graphene yield is about 4.1%.

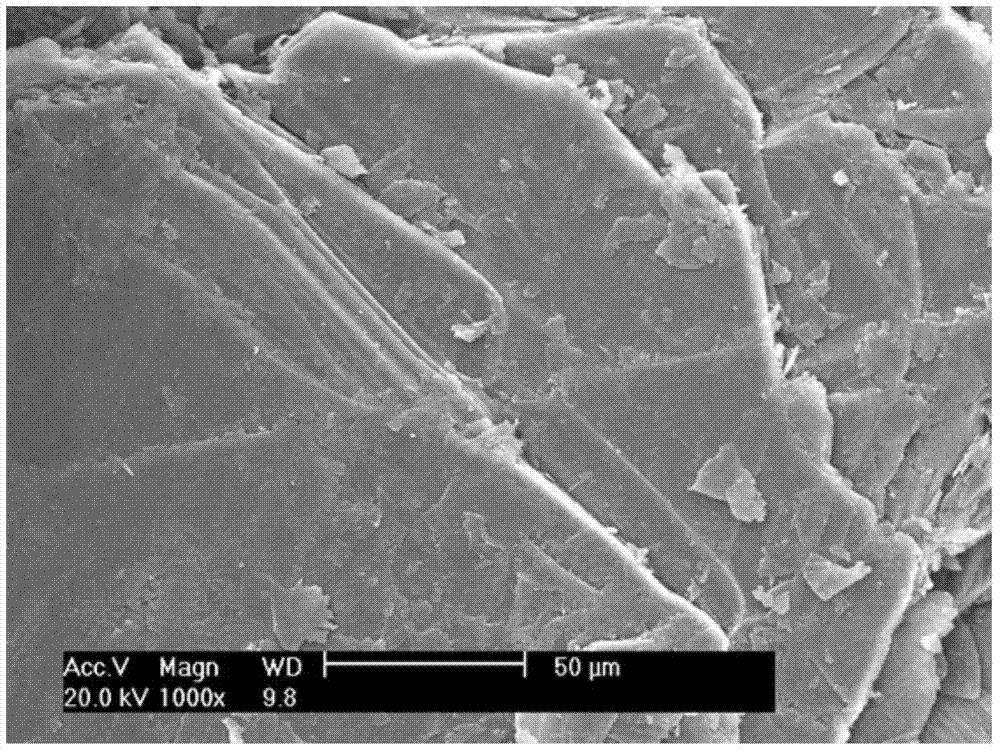

[0041] The graphite powder before the preparation of the present embodiment is detected, and the scanning electron microscope picture is as follows: figure 1 shown;

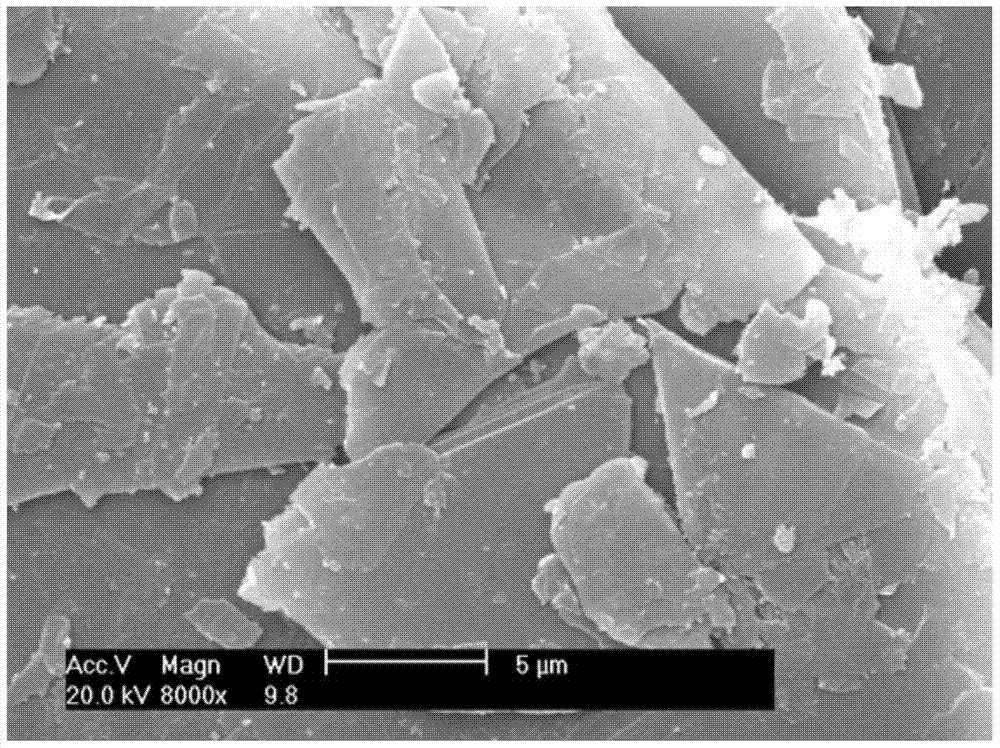

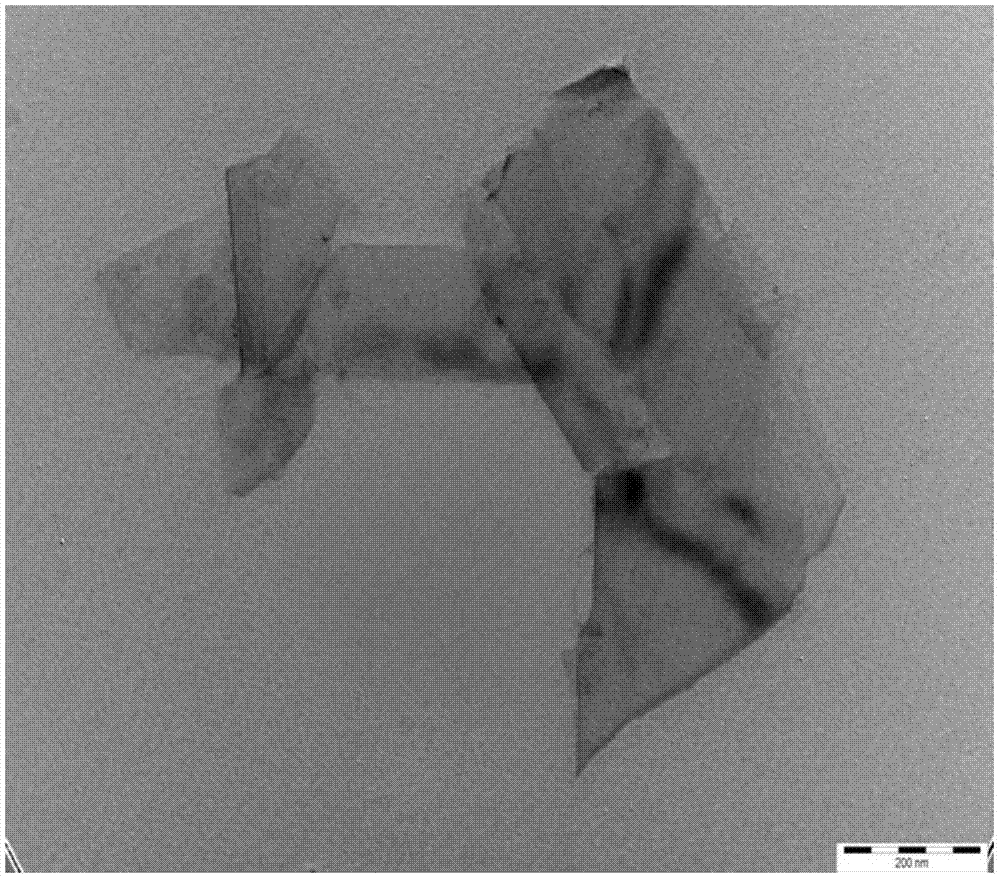

[0042] Various detections are carried out to the graphene prepared by the present embodiment, and the scanning electron microscope picture is as follows figure 2 The transmission electron microsc...

Embodiment 2

[0044] Add 1g of graphite powder to 120mL of water, the size of the graphite powder is 10 microns, place in a closed reaction kettle, stir at 500rpm, and heat to 300°C, keep for 3 hours for hydrothermal exfoliation. After cooling, the solution was centrifuged at a speed of 10,000 rpm for 30 min, and the upper layer liquid after centrifugation was taken with a pipette to obtain a graphene dispersion uniformly dispersed in a mixed solvent. The graphene dispersion was subjected to high-speed centrifugation at 10000 rpm for 5 minutes to obtain the lower solid which was graphene. The yield of graphene is about 3.2% by weight.

Embodiment 3

[0046] Add 1g of graphite powder to 120mL of water, the size of graphite powder is 500 microns, place in a closed reaction kettle, stir at 1500rpm, and heat to 180°C, keep for 6 hours for hydrothermal exfoliation. After cooling, the solution was centrifuged at a speed of 500 rpm for 90 min, and the upper layer liquid after centrifugation was taken with a pipette to obtain a graphene dispersion uniformly dispersed in a mixed solvent. The graphene dispersion was centrifuged at 8000 rpm for 90 minutes at a high speed to obtain the lower solid which was graphene. The yield of graphene is about 2.4% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com