Treatment process for degradation of high-concentration organic matter and reduction of total nitrogen in printing and dyeing wastewater

A printing and dyeing wastewater and treatment process technology, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of improving denitrification effect, optimizing treatment process, and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

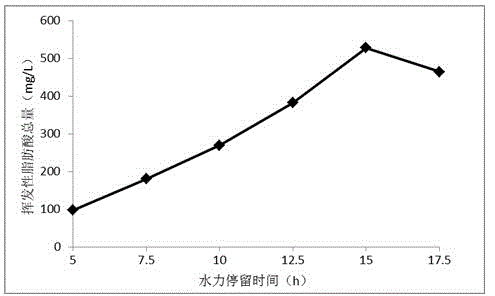

[0022] The raw water in the examples is taken from the wastewater regulating pond of a printing and dyeing enterprise, and is divided into pretreatment wastewater and dyeing wastewater. The pretreatment wastewater is mainly composed of wastewater generated from desizing, scouring and rinsing. Dyeing wastewater is mainly composed of dyeing, printing and denim wastewater, and the influent water quality is shown in Table 1. UASB inoculation sludge adopts citric acid plant granular sludge, MLSS in which the mass concentration ratio of volatile suspended solids and suspended solids in the inoculation sludge is ρ(VSS) / ρ(SS)=0.70. The ρ(SS) of inoculated sludge=50.33g / L. The seed mud is black, and the particle size is mainly 1-3mm. The ascending velocity of the UASB reactor is 1m / h, and the temperature is controlled at 35-40°C. By adjusting the anaerobic hydrolysis time of dyeing wastewater, the production of volatile fatty acids is controlled. result( figure 1 , Table 2) show th...

Embodiment 2

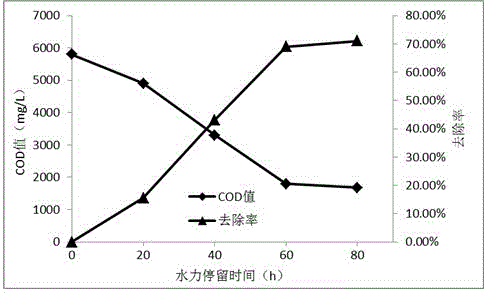

[0028] The raw water in the examples is taken from the wastewater regulating pond of a printing and dyeing enterprise, and is divided into pretreatment wastewater and dyeing wastewater. The pretreatment wastewater is mainly composed of wastewater generated from desizing, scouring and rinsing. Dyeing wastewater is mainly composed of dyeing, printing and denim wastewater, and the influent water quality is shown in Table 1. UASB inoculation sludge adopts citric acid plant granular sludge, MLSS in which the mass concentration ratio of volatile suspended solids and suspended solids in the inoculation sludge is ρ(VSS) / ρ(SS)=0.70. The ρ(SS) of inoculated sludge=50.33g / L. The seed mud is black, and the particle size is mainly 1-3mm. The ascending velocity of the UASB reactor is 1m / h, and the temperature is controlled at 35-40°C. Adjust the pre-treatment wastewater hydraulic retention time to 20h, 40h, 60h, 80h respectively. result( figure 2 ) shows that when the hydraulic retenti...

Embodiment 3

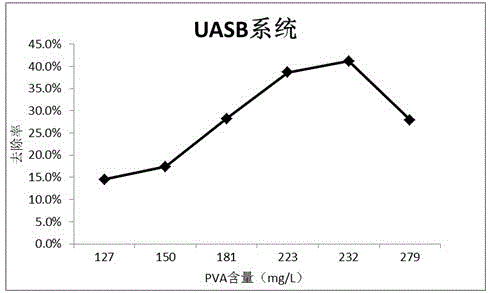

[0030] The raw water in the examples is taken from the wastewater regulating pond of a printing and dyeing enterprise, and is divided into pretreatment wastewater and dyeing wastewater. The pretreatment wastewater is mainly composed of wastewater generated from desizing, scouring and rinsing. Dyeing wastewater is mainly composed of dyeing, printing and denim wastewater, and the influent water quality is shown in Table 1. UASB inoculation sludge adopts citric acid plant granular sludge, MLSS in which the mass concentration ratio of volatile suspended solids and suspended solids in the inoculation sludge is ρ(VSS) / ρ(SS)=0.70. The ρ(SS) of inoculated sludge=50.33g / L. The seed mud is black, and the particle size is mainly 1-3mm. The ascending velocity of the UASB reactor is 1m / h, and the temperature is controlled at 35-40°C. The hydraulic retention time of the pre-treatment wastewater is 60h, and the hydraulic retention time of the dyeing wastewater is 15h. The two effluents are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com