Method for synthesis of sialon ceramic fiber by combination of electrostatic spinning and carbothermal reduction nitridation

A technology of ceramic fiber and electrospinning, which is applied in the field of high-temperature structural ceramic fiber preparation, can solve problems such as large limitations, and achieve the effects of simple equipment, adjustable components, and mild and controllable preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

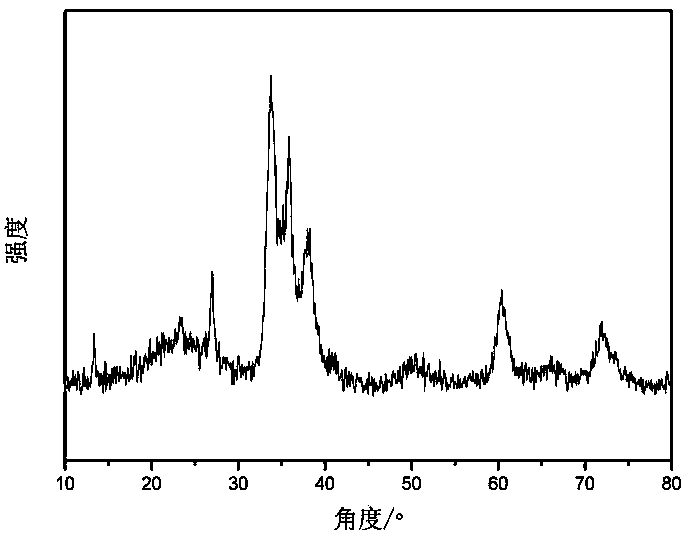

Embodiment 1

[0039] Use the first type of aluminum source: aluminum nitrate nonahydrate to prepare Sialon ceramic fiber. The mass ratio of aluminum nitrate nonahydrate, ethyl orthosilicate and sucrose is 1:1:0.93. Other raw materials and their proportioning and preparation methods are as follows: (1) Weigh 4.65g of sucrose and 5g of aluminum nitrate nonahydrate and add them to the mixed solution of 20g of water and 5g of ethanol, stir well to dissolve. Then add 3.5g of polyvinylpyrrolidone, and stir until transparent viscous liquid. (2) Weigh 5g of ethyl orthosilicate, add it to the mixture of 5g of absolute ethanol and 1g of water, stir for 2 hours, and mix well. (3) Mix the solution prepared in step (2) with the solution prepared in step (1), and stir for 1 hour to obtain a spinning dope. (4) Add the prepared spinning stock solution into the syringe, adjust the spinning voltage to 15kV, the propulsion speed parameter of the syringe is 1ml / h, the needle is No. 7 needle, the receiving dev...

Embodiment 2

[0041] Use the first type of aluminum source: aluminum nitrate nonahydrate to prepare Sialon ceramic fiber. The mass ratio of aluminum nitrate nonahydrate, ethyl orthosilicate and sucrose as the raw material is 2:1:0.9 as an example. Other raw materials and their proportions and preparation methods As follows: (1) Weigh 3.6g of sucrose and 8g of aluminum nitrate nonahydrate and add them to 25g of water, stir well to dissolve. Then add 3.8g of polyvinylpyrrolidone, stir until transparent viscous liquid. (2) Weigh 4g of tetraethyl orthosilicate, add it to the mixture of 6g of absolute ethanol and 1g of water, stir for 2 hours, and mix well. (3) Mix the solution prepared in step (2) with the solution prepared in step (1), and stir for 2 hours to obtain a spinning stock solution. (4) Add the prepared spinning stock solution into the syringe, adjust the spinning voltage to 20kV, the propulsion speed parameter of the syringe is 4ml / h, the needle is No. 6 needle, the receiving devic...

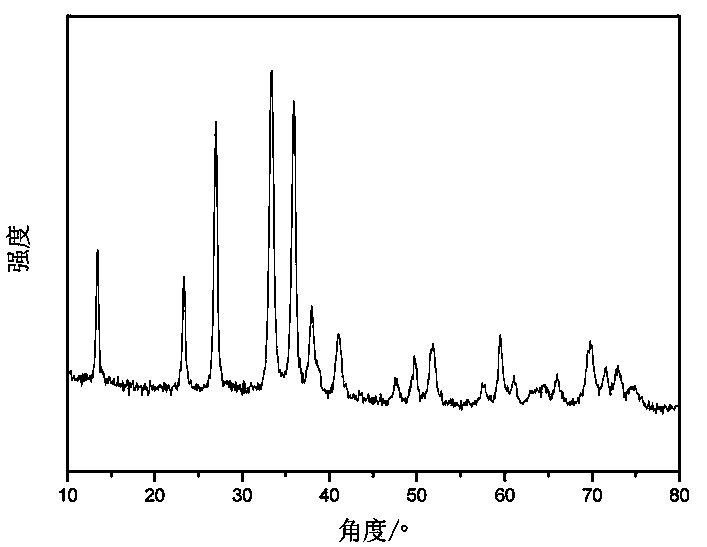

Embodiment 3

[0043] Use the first type of aluminum source: aluminum nitrate nonahydrate to prepare Sialon ceramic fiber. The mass ratio of aluminum nitrate nonahydrate, ethyl orthosilicate and sucrose as the raw material is 3:1:1.3 as an example. Other raw materials and their proportioning and preparation methods As follows: (1) Weigh 3.9g of sucrose and 9g of aluminum nitrate nonahydrate and add them to the mixed solution of 20g of water and 12g of ethanol, stir well to dissolve. Then add 4g of polyvinylpyrrolidone and stir until transparent viscous liquid. (2) Weigh 3g of ethyl orthosilicate, add it to the mixture of 3g of absolute ethanol and 1g of water, stir for 2h, and mix well. (3) Mix the solution prepared in step (2) with the solution prepared in step (1), and stir for 2 hours to obtain the spinning source solution. (4) Add the prepared spinning stock solution into the syringe, adjust the spinning voltage to 10kV, the propulsion speed parameter of the syringe is 0.2ml / h, the need...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com