Method for increasing yield of BTX aromatics

A BTX aromatics, aromatics technology, applied in chemical instruments and methods, bulk chemical production, hydrocarbons, etc., can solve the problem of low non-aromatic utilization value, improve the added value of products, achieve significant technical effects, and realize the heat of reaction. self-sufficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

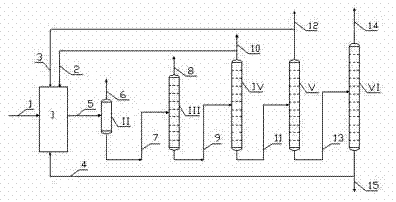

[0023] with C 6 And the mixture of the above components is the raw material (the content of benzene is 24.4 tons / hour, the content of toluene is 9.3 tons / hour, the content of xylene is 2.1 tons / hour, and the content of ethylbenzene is 3.6 tons / hour). figure 1 Process technology increases production of BTX, of which benzene, toluene, C 9 +None cycle. Reaction unit, reaction pressure 2.8 MPa, reaction temperature 350°C, hydrogen partial pressure 1.4 MPa; stripping column is a 44-layer float valve tray, the operating pressure at the top of the tower is 0.7MPa, the control temperature of the top separator is 40°C, discharge Non-condensable gas, in which the molar concentration of ethane is 47.1%, the molar concentration of propane is 39.9%, and other light hydrocarbons are 13.0mol%. The benzene tower adopts 55 layers of valve trays, the operating pressure at the top of the tower is 0.05MPa, and 21 tons / hour of benzene products with a purity of 99.95wt% are obtained at the top o...

Embodiment 2

[0026] Highly non-aromatic cracking C 9 + As raw material (toluene content is 3.1 tons / hour), using figure 1 Process technology increases production of BTX, of which benzene, toluene, C 9 + None cycle. Reaction unit, reaction pressure 2.8 MPa, reaction temperature 340°C, hydrogen partial pressure 1.14 MPa; stripping tower is a 44-layer float valve tray, the operating pressure at the top of the tower is 0.7MPa, the control temperature of the top separator is 40°C, discharge Non-condensable gas, in which the molar concentration of ethane is 23.3%, the molar concentration of propane is 63.3%, and other light hydrocarbons are 13.4mol%. The benzene tower adopts 55 layers of valve trays, the operating pressure at the top of the tower is 0.05MPa, and 8.4 tons / hour of benzene product with a purity of 99.95wt% is obtained at the top of the tower. The toluene tower adopts 55 layers of valve trays, the operating pressure at the top of the tower is 0.05MPa, and 14.2 tons / hour of tolu...

Embodiment 3

[0029] to reform C 9 + as raw material (benzene content is 0 tons / hour, toluene content is 30.5 tons / hour, xylene content is 42.3 tons / hour, C 9 + Aromatics content is 504.5 tons / hour), using figure 1 Process technology increases production of BTX, of which benzene, toluene, C 9 + None cycle. Reaction unit, reaction pressure 2.6 MPa, reaction temperature 320°C, hydrogen partial pressure 1.04 MPa; stripping column is a 44-layer float valve tray, the operating pressure at the top of the tower is 0.7MPa, the control temperature of the top separator is 40°C, discharge Non-condensable gas, in which the molar concentration of ethane is 18.3%, the molar concentration of propane is 63.3%, and other light hydrocarbons are 18.4mol%. The benzene tower adopts 55 layers of valve trays, the operating pressure at the top of the tower is 0.05MPa, and 53.7 tons / hour of benzene product with a purity of 99.95wt% is obtained at the top of the tower. The toluene tower adopts 55 layers of va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com