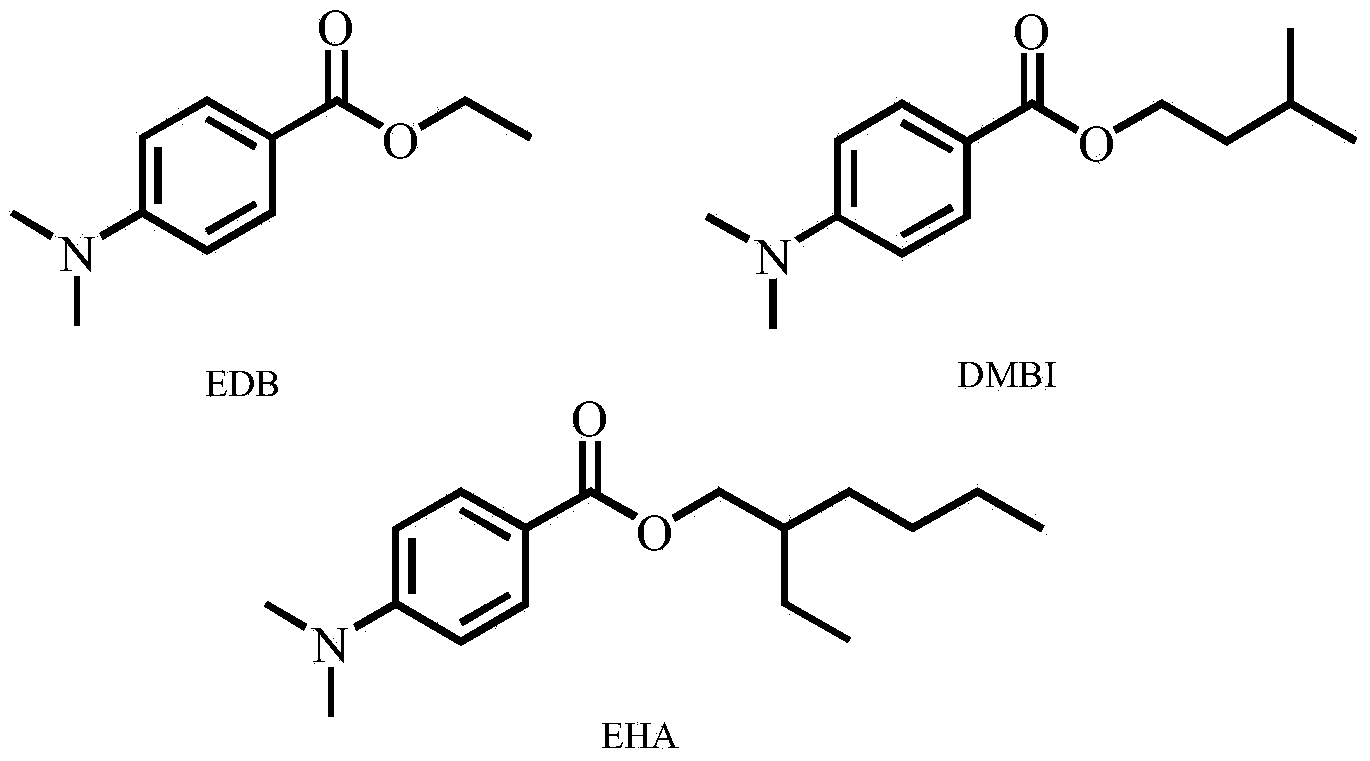

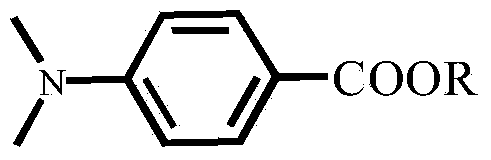

Preparation method for p-dimethylamino benzoate compounds of ultraviolet initiating agent

A technology of dimethylaminobenzoic acid and ester compounds, which is applied in the field of preparation of p-dimethylaminobenzoic acid ester compounds as an ultraviolet photoinitiator, and can solve the problems of unfriendly environment, high production cost, and low yield of esterification , to achieve the effect of reducing production cost, less risk, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

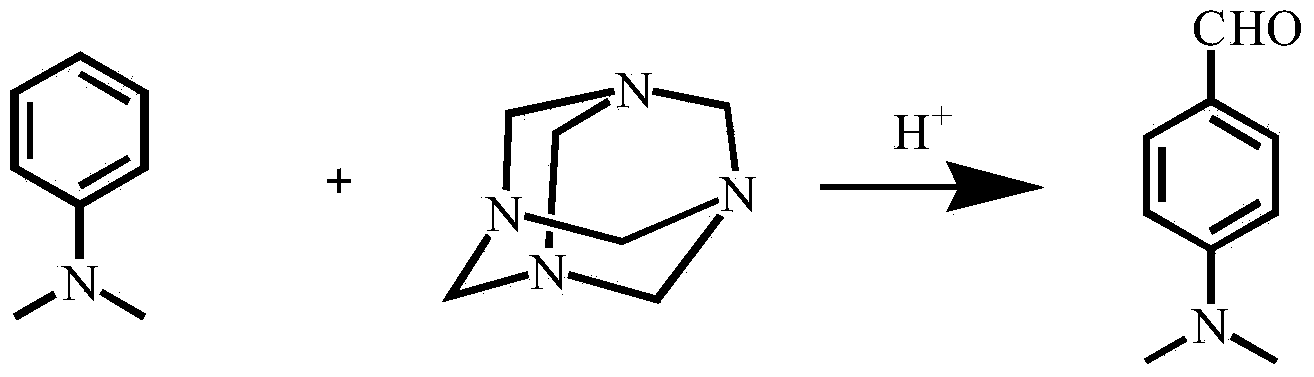

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation of methyl p-dimethylaminobenzoate

[0028] In a 500ml four-necked bottle, add 250ml methanol, 7g ferric perchlorate hexahydrate, and 53.0g p-dimethylaminobenzaldehyde. Cool the reaction to about -5°C, add 43ml of 33% hydrogen peroxide dropwise to the reaction, and the dropwise addition is completed in about 1 hour. After the dropwise addition is completed, slowly rise to room temperature for 3 hours. TLC or GC monitors the reaction end point. After the reaction is complete, the methanol is recovered by distillation under normal pressure and then under reduced pressure. The residue is rectified under reduced pressure to obtain 58 g of the product (conditions for collecting fractions: 101-105 °C / 0.05 mm Hg), and the yield is 91.0 %, purity 99.2%.

Embodiment 2

[0029] Embodiment 2: the preparation of methyl p-dimethylaminobenzoate

[0030] In a 500ml four-neck flask, add 250ml methanol, 10g ferric perchlorate hexahydrate, and 53.0g p-dimethylaminobenzaldehyde. Cool the reaction to about -5°C, add 43ml of 33% hydrogen peroxide dropwise to the reaction, and the dropwise addition is completed in about 1 hour. After the dropwise addition is completed, slowly rise to room temperature for 3 hours. TLC or GC monitors the end point of the reaction. After the reaction is complete, methanol is recovered by distillation under normal pressure and then under reduced pressure. The residue is rectified under reduced pressure to obtain 57.1 g of the product (conditions for collecting fractions: 101-105 °C / 0.05 mm Hg). 90.5%, purity 99.4%.

Embodiment 3

[0031] Embodiment 3: the preparation of ethyl p-dimethylaminobenzoate

[0032] In a 500ml four-necked bottle, add 300ml ethanol, 7g ferric perchlorate hexahydrate, and 53.0g p-dimethylaminobenzaldehyde. Cool the reaction to about -5°C, add 43ml of 33% hydrogen peroxide dropwise to the reaction, and the dropwise addition is completed in about 1 hour. After the dropwise addition is completed, slowly rise to room temperature for 3 hours. TLC or GC monitors the end point of the reaction. After the reaction is complete, the solvent is recovered by distillation under normal pressure and then under reduced pressure. The residue is rectified under reduced pressure to obtain 64.2g of the product (conditions for collecting fractions: 110~115°C / 0.02mm Hg), the yield 93.5%, purity 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com