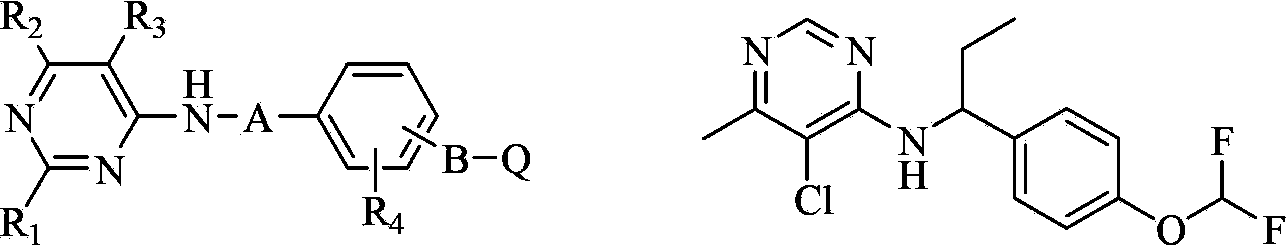

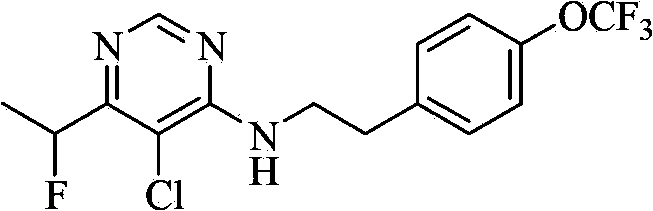

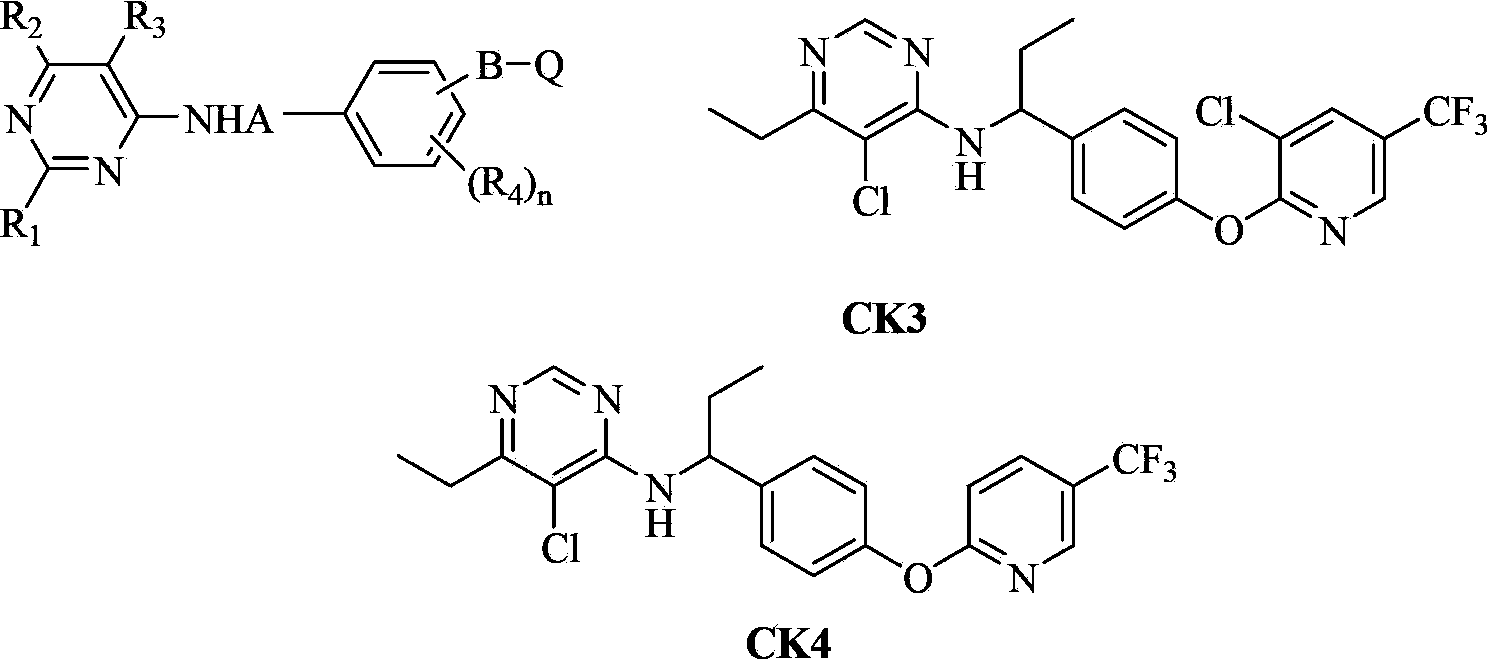

Phenoxyl pyrilamine compound and application

A technology of phenoxypyrimidine amines and compounds, which is applied in the field of phenoxypyrimidine amines and can solve the problems that the structure of phenoxypyrimidine amines has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0240] Example 1: Preparation of intermediate 4,5-dichloro-6-methylpyrimidine

[0241] 1) Preparation of 4-hydroxy-5-chloro-6-methylpyrimidine

[0242]

[0243] Under stirring at room temperature, to 11.30g (0.11mol) of formamidine acetate in 50ml of methanol was slowly added dropwise 8.80g (0.16mol) of sodium methoxide in methanol, after dripping at room temperature, continue to stir for 2h. Then 11.17g (0.068mol) of the intermediate ethyl 2-chloroacetoacetate was added dropwise to the above solution, and the reaction was stirred at room temperature for 5-7 hours. After the reaction was monitored by TLC, the solvent was evaporated under reduced pressure, and the pH was adjusted to 5 with hydrochloric acid. ~6, suction filtration to obtain an orange-yellow solid, the aqueous phase was extracted with (3×50ml) ethyl acetate, dried with anhydrous magnesium sulfate, filtered and desolventized. The residue was dissolved in 50 ml of ethyl acetate, left overnight, and filtered to obtain ...

Embodiment 2

[0247] Example 2: Preparation of intermediate 4-(2-chloro-4-trifluoromethylphenoxy)phenethylamine

[0248] 1) Preparation of 4-(2-chloro-4-trifluoromethylphenoxy)benzeneacetonitrile

[0249]

[0250] Add 25.8g (0.12mol) of 3,4-dichlorotrifluoromethylbenzene, 13.3g (0.1mol) of p-hydroxybenzeneacetonitrile and 27.60g (0.2mol) of potassium carbonate to 150ml of N,N-dimethylformamide After stirring, heat to reflux and react overnight. After the reaction is monitored by TLC, the solvent is evaporated under reduced pressure, and 300ml of ethyl acetate is added for extraction. The organic phase is washed with 5% sodium hydroxide aqueous solution and 50ml saturated brine in turn. After desolvation Column chromatography of the residue (eluent is ethyl acetate and petroleum ether (boiling range 60-90°C), volume ratio 1:4) to obtain 14.55 g of white solid, yield 46.2%, melting point 66.2°C.

[0251] 2) Preparation of 4-(2-chloro-4-trifluoromethylphenoxy)phenethylamine hydrochloride

[0252]

[...

Embodiment 3

[0254] Example 3: Preparation of intermediate 4-(2,6-dichloro-4-nitrophenoxy)phenethylamine hydrochloride

[0255] 1) Preparation of N-Boc-4-hydroxyphenethylamine

[0256]

[0257] Dissolve 11.3g (0.1mol) 4-hydroxyphenethylamine in 80ml tetrahydrofuran, add 10.08g (0.12mol) sodium bicarbonate, 50ml water, 21.80g (0.1mol) di-tert-butyl dicarbonate with stirring at room temperature After dropping the ester, continue the reaction for 4-10 hours. After the reaction is monitored by TLC, the solvent is evaporated under reduced pressure, and (3×50ml) ethyl acetate is added for extraction. The organic phase is washed with 50ml of saturated brine. Chromatography (eluent is ethyl acetate and petroleum ether (boiling range 60-90°C), volume ratio 1:3) to obtain 23.37g of colorless oily liquid, yield 98.6%.

[0258] 2) Preparation of N-Boc-4-(2,6-dichloro-4-nitrophenoxy)phenethylamine

[0259]

[0260] Add 2.10g (0.01mol) N-Boc-4-hydroxyphenethylamine and 2.33g (0.01mol) 3,5-dichloro-4-fluoronitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com