A kind of cerium-doped lutetium disilicate scintillation fiber and its electrospinning synthesis method

A technology of scintillation fibers and electrospinning, which is applied in the directions of fiber processing, filament/thread forming, spinning solution preparation, etc., to achieve the effects of excellent scintillation performance, controllable fiber forming, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

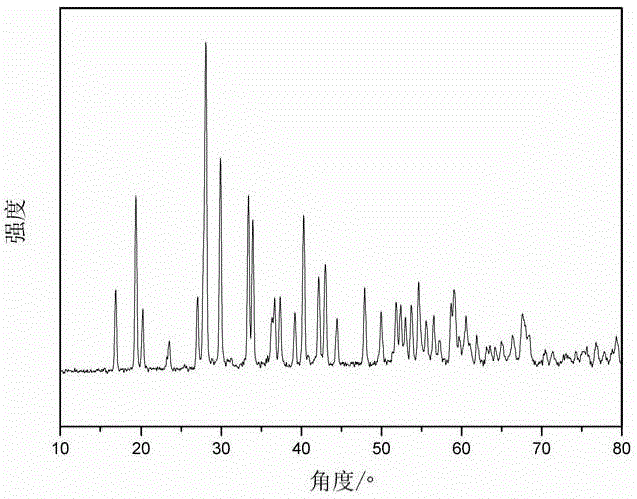

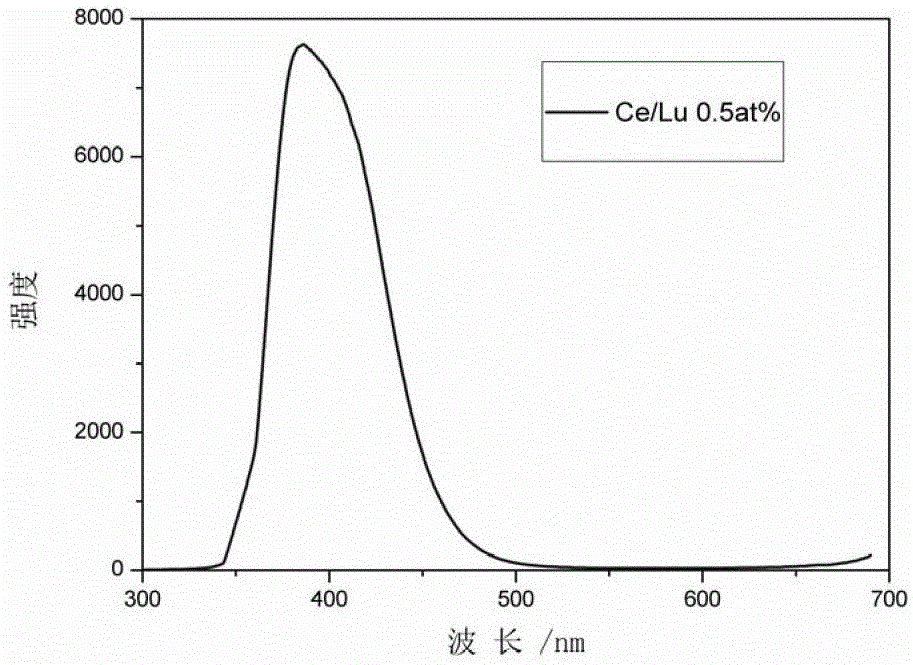

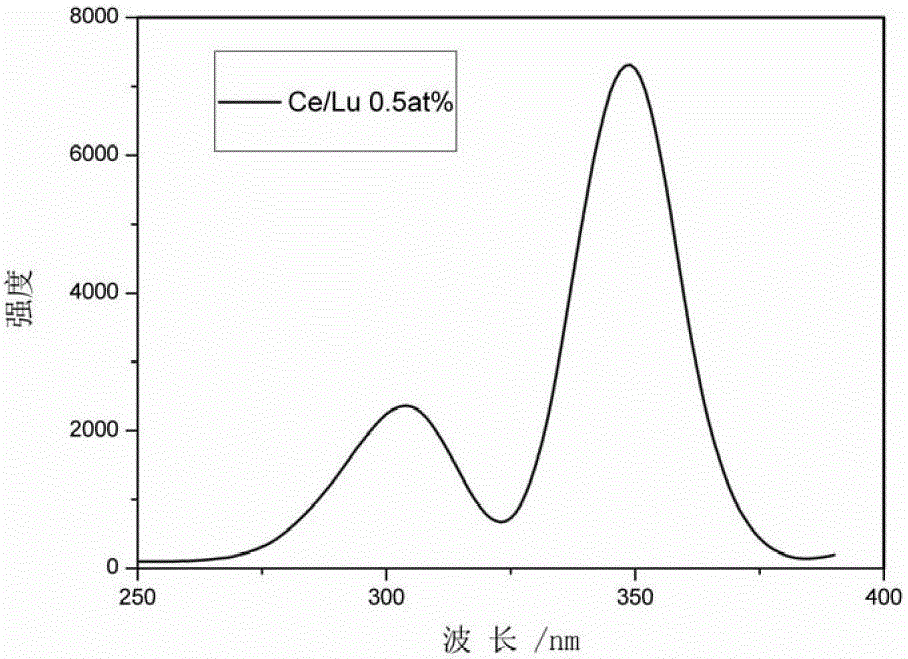

Image

Examples

Embodiment 1

[0039] (1) Weigh 4.64g of lutetium oxide, add 20g of concentrated nitric acid, heat and stir until dissolved, then evaporate the solution to obtain white solid lutetium nitrate; (2) add 20g of ethanol, stir and dissolve the solid lutetium nitrate, and then add 0.1012g of cerium nitrate, then add 1.2g of polyvinyl butyral, and stir until a transparent viscous liquid; (3) Weigh 5g of tetraethyl orthosilicate, add it to the mixed solution of 5g of absolute ethanol and 1g of water, Then add 0.1g of concentrated hydrochloric acid, stir for 4 hours, and mix well; (4) combine the steps

[0040] (2) The prepared solution is mixed with the solution prepared in step (3), and after stirring for 1 hour, the spinning source solution is obtained; (5) The prepared spinning stock solution is added to the syringe, and the spinning voltage is adjusted to 10kV, The injection speed parameter is 0.5ml / h, the needle is No. 6 needle, the receiving device is a roller, the roller speed is 10m / min, the...

Embodiment 2

[0042] (1) Weigh 4.64g of lutetium oxide, add 18g of concentrated nitric acid, heat and stir until dissolved, then evaporate the solution to obtain white solid lutetium nitrate; (2) add 10g of ethanol, stir and dissolve the solid lutetium nitrate, and then add 0.2024g of cerium nitrate, then add 0.8g of polyvinyl butyral, and stir until a transparent viscous liquid; (3) Weigh 5g of tetraethyl orthosilicate, add it to the mixed solution of 5g of absolute ethanol and 1g of water, Then add 0.1g of concentrated hydrochloric acid, stir for 4 hours, and mix well; (4) Mix the solution prepared in step (2) with the solution prepared in step (3), and stir for 1 hour to obtain the spinning source solution; (5) Mix The prepared spinning stock solution is added to the syringe, the spinning voltage is adjusted to be 20kV, the injection speed parameter is 2ml / h, the needle is No. 5 needle, the receiving device is a drum, the drum speed is 10m / min, the cylinder length is 300mm, the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com