Graphene-carbon nanotube composite material, and preparation method and application thereof

A technology of carbon nanotubes and composite materials, which is applied in the field of graphene-carbon nanotube composite materials and its preparation, can solve the problems of low power density and achieve the effects of high power density, cheap and easy-to-obtain raw materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

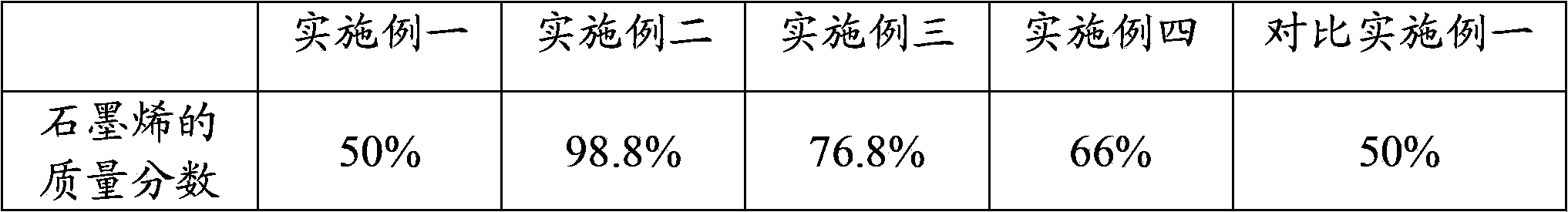

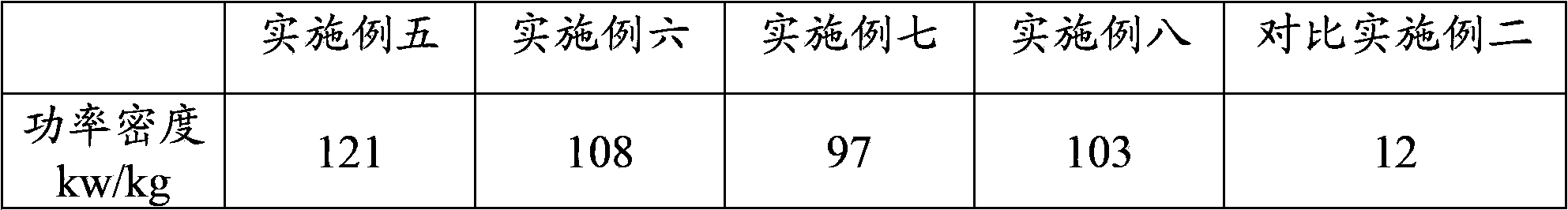

Embodiment 1

[0031] A preparation method of graphene-carbon nanotube composite material, comprising the following steps:

[0032] (1) Weigh 8.3g of graphite oxide and 4.15g of carbon nanotubes into 12.45L of deionized water, and ultrasonicate for 1 hour to obtain a graphene oxide-carbon nanotube dispersion with a mass fraction of 0.1%;

[0033] (2) Add 8.3L of 50% nitric acid solution while stirring, and ultrasonically treat at 25°C for 2 hours to obtain a suspension of graphene oxide-carbon nanotubes-nitric acid; at this time, nitric acid is bound to graphene oxide-carbon on nanotubes, and endow some carbon atoms with oxygen-containing functional groups;

[0034] (3) Filter the suspension in step (2), put the filtered filter cake in a vacuum drying oven, and dry at 60°C for 48 hours to obtain a solid powder, and then put the solid powder into a muffle furnace , calcined at a high temperature of 800°C for 5 hours, after cooling, pour deionized water into the powder for soaking and washing...

Embodiment 2

[0036] A preparation method of graphene-carbon nanotube composite material, comprising the following steps:

[0037] (1) Weigh 16.5g of graphite oxide and 0.1g of carbon nanotubes into 33.2L of deionized water, and ultrasonicate for 5 hours to obtain a graphene oxide-carbon nanotube dispersion with a mass fraction of 0.05%;

[0038] (2) Add 165L of 70% nitric acid solution while stirring, and ultrasonicate for 1 hour at 20°C to obtain a graphene oxide-carbon nanotube-nitric acid suspension; at this time, nitric acid is bound to graphene oxide-carbon nano On the tube, and endow some carbon atoms with oxygen-containing functional groups;

[0039] (3) Filter the suspension in step (2), put the filtered filter cake in an oven, and dry at 80°C for 24 hours to obtain a solid powder, and then put the solid powder into a graphite furnace to heat at 1200 ℃ high temperature heat treatment for 1 hour, after cooling, pour deionized water into the powder for soaking and rinsing, filter th...

Embodiment 3

[0041] A preparation method of graphene-carbon nanotube composite material, comprising the following steps:

[0042] (1) Weigh 13.3g of graphite oxide and 2g of carbon nanotubes into 3L of distilled water, and ultrasonicate for 2 hours to obtain a graphene oxide-carbon nanotube dispersion with a mass fraction of 0.5%;

[0043] (2) Add 199.5L of 65% nitric acid solution while stirring, and ultrasonically treat at 30°C for 1.5 hours to obtain a suspension of graphene oxide-carbon nanotubes-nitric acid; at this time, nitric acid is bound to graphene oxide-carbon on nanotubes, and endow some carbon atoms with oxygen-containing functional groups;

[0044] (3) Filter the suspension in step (2), put the filtered filter cake in an oven, and dry at 70°C for 36 hours to obtain a solid powder, and then put the solid powder into a muffle furnace to Heat treatment at 1000°C for 3 hours. After cooling, pour distilled water into the powder for soaking and rinsing. Filter the filter residue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com