Astaxanthin apple vinegar beverage and fabrication method thereof

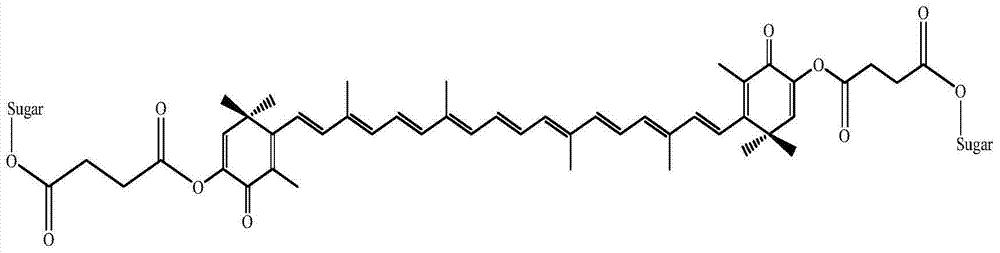

A technology of astaxanthin and apple cider vinegar, applied in the preparation of vinegar, food preparation, function of food ingredients, etc., can solve the problem of insolubility of astaxanthin in water, etc., to improve immunity, regulate blood lipids, and eliminate fatigue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

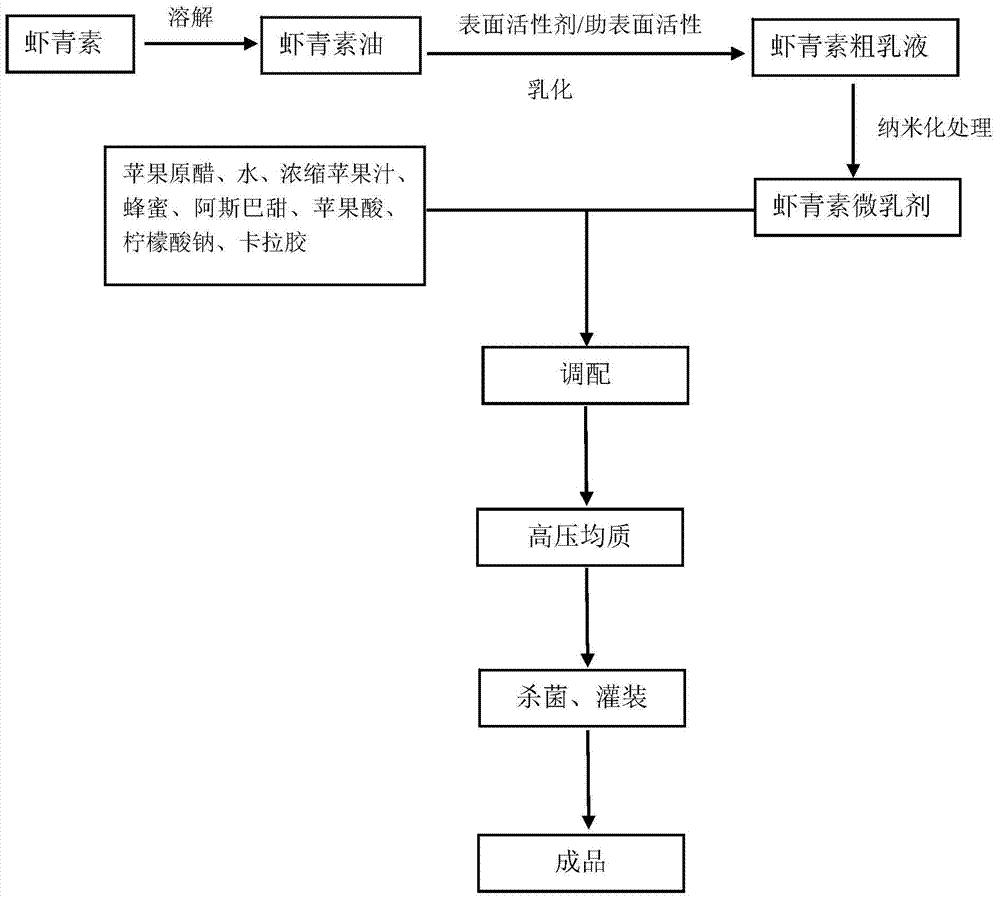

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of astaxanthin microemulsion

[0031] ① Take the astaxanthin from Haematococcus pluvialis as the raw material, weigh 1kg of the astaxanthin raw material, add it to 8kg of corn oil preheated to 40℃, in CO 2 Stir under protection until it dissolves to obtain astaxanthin oil.

[0032] ②Add 8 times the mass of a mixture of Tween 40 and 1,2-propanediol preheated to 40°C to the astaxanthin oil prepared in step ①, and stir at 200r / min for 20 minutes to mix evenly to obtain a mixed liquid. The mass ratio of Tween 40 and 1,2-propanediol is 1:2.

[0033] ③Under low-speed stirring at 100r / min, slowly pour the mixture obtained in step ② into 2 times the volume of water, and then stir at 1000r / min for 15 minutes at a high speed to make it evenly mixed and cool to room temperature.

[0034] ④The mixed liquid obtained in step ③ is emulsified for 20 minutes at a speed of 10000r / min to obtain a coarse emulsion.

[0035] ⑤ Nano-treatment: homogenize the crude emulsion prepared in ...

Embodiment 2

[0040] (1) Preparation of astaxanthin microemulsion

[0041] ①Weigh 1g synthetic astaxanthin, add it to 10g olive oil preheated to 60℃, and add it to N 2 Stir under protection until it dissolves to obtain astaxanthin oil.

[0042] ②Add 9 times the mass of the mixture of sucrose mono-fatty acid esters and glycerol preheated to 30°C to the astaxanthin oil prepared in step ①, and stir for 10 min under the condition of 300r / min to make it evenly mixed. In the mixed liquid, the mass ratio of sucrose mono-fatty acid ester and glycerol is 1:2.

[0043] ③ Under low-speed stirring at 200r / min, slowly pour the mixture prepared in step ② into 3 times the volume of water, and then stir at 800r / min for 20 minutes at high speed to make it evenly mixed and cool to room temperature.

[0044] ④The mixture obtained in step ③ is emulsified for 10 minutes at a rotation speed of 8000r / min to obtain a coarse emulsion.

[0045] ⑤ Nano-treatment: the crude emulsion prepared in step ④ is treated under 25KHz ul...

Embodiment 3

[0050] (1) Preparation of astaxanthin microemulsion

[0051] ① Weigh 10g of astaxanthin derived from Phaffia rhodozyma and add it to 60g of soybean oil preheated to 40℃. 2 Stir under protection until it dissolves to obtain astaxanthin oil.

[0052] ②Add 10 times the mass of a mixture of lecithin and ethanol preheated to 40℃ to the astaxanthin oil prepared in step ①, and stir at 150r / min for 30min to make it evenly mixed to obtain a mixed liquid. The mass ratio of phospholipids to ethanol is 1:2.

[0053] ③ Under low-speed stirring of 150r / min, slowly pour the mixture prepared in step ② into 2.5 times the volume of water, and then stir at high speed for 30min under the condition of 900r / min to make it evenly mixed and cool to room temperature.

[0054] ④The mixed liquid obtained in step ③ is emulsified for 5 minutes at a rotation speed of 15000r / min to obtain a coarse emulsion.

[0055] ⑤ Nano-treatment: homogenize the crude emulsion prepared in step ④ under a pressure of 60 MPa, so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com