Hydrogen production water ceramic material, and preparation method and application of hydrogen production water ceramic material

A technology of ceramic materials and raw materials, which is applied in the field of hydrogen production water ceramic materials and its preparation, can solve the problems of easy precipitation of precipitates, uncontrollable alkalinity, low hydrogen production content, etc., and achieve simple process, good timeliness and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Another aspect of the present invention also provides a kind of preparation method of above-mentioned hydrogen production water ceramic material, comprises the following steps: (1) tourmaline, medical stone, calcium oxide, calcium carbonate, diatomaceous earth, silicon oxide, chitosan Sugar, metal magnesium powder, KDF alloy and antibacterial components are mixed to obtain a mixture A; the binder is added to water or an organic solvent to dissolve to obtain a mixed solution; (2) the mixture A prepared in step (1) is added to the prepared Stir in the mixed solution to obtain mixture B; (3) bake the mixture B prepared in step (2) in vacuum under the protection of hydrogen or inert gas to obtain the hydrogen-producing water ceramic material. In the above preparation method, the mixture B is baked in vacuum or under the protection of hydrogen or inert gas to prepare the hydrogen-producing water ceramic material, which can protect the metal magnesium powder from being oxidize...

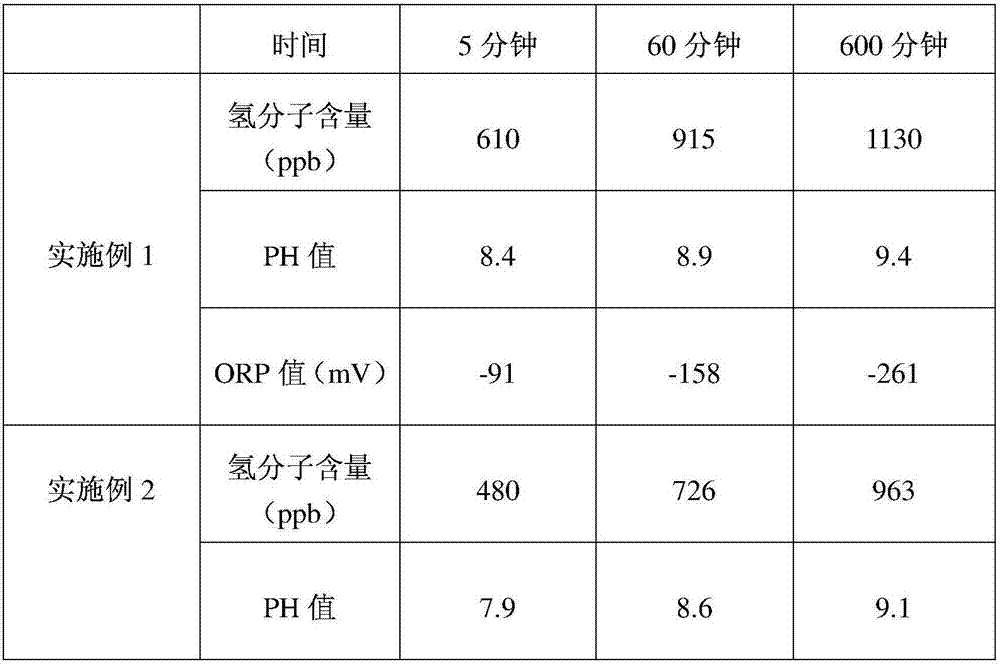

Embodiment 1

[0048] A preferred embodiment of the present invention provides a ceramic material for hydrogen production water, which is mainly made of the following raw materials: 7.43g tourmaline, 1.32g medical stone, 1.06g calcium oxide, 1.06g calcium carbonate, 0.91g diatomite, Quartz sand 1.93g, chitosan 1.23g, metal magnesium powder 4.20g, KDF alloy 0.38g, titanium oxide 0.21g, zinc oxide 0.21g, ethyl cellulose 1.27g.

[0049] Preferred embodiment of the present invention also provides the preparation method of above-mentioned hydrogen production water ceramic material, comprises the following steps:

[0050] (1) Weigh tourmaline 7.43g, medical stone 1.32g, calcium oxide 1.06g, calcium carbonate 1.06g, diatomite 0.91g, quartz sand 1.93g, chitosan 1.23g, metal magnesium powder 4.20g, Add 0.38g of KDF alloy, 0.21g of titanium oxide, and 0.21g of zinc oxide into a mixer and mix for 2 hours to obtain mixture A; weigh 1.27g of ethyl cellulose, add it to 30ml of absolute ethanol, heat and s...

Embodiment 2

[0054] The preferred embodiment of the present invention provides a ceramic material for hydrogen production water, which is mainly made of the following raw materials: 6.03g of tourmaline, 2.69g of medical stone, 1.76g of calcium oxide, 1.02g of calcium carbonate, 1.39g of diatomite, Quartz sand 2.67g, chitosan 0.97g, metal magnesium powder 3.43g, KDF alloy 0.67g, silver 0.36g, zinc oxide 0.25g, titanium oxide 0.18g, methyl cellulose 0.83g and natural potassium feldspar 0.45g, Bentonite 0.38g.

[0055] Preferred embodiment of the present invention also provides the preparation method of above-mentioned hydrogen production water ceramic material, comprises the following steps:

[0056] (1) Weigh tourmaline 6.03g, medical stone 2.69g, calcium oxide 1.76g, calcium carbonate 1.02g, diatomite 1.39g, quartz sand 2.67g, chitosan 0.97g, metal magnesium powder 3.43g, 0.67g of KDF alloy, 0.36g of silver, 0.25g of zinc oxide, and 0.18g of titanium oxide were added to the mixer and mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com