Method for synthesizing heterogeneous atom doped carbon material through one-step process

A technology of carbon materials and heterogeneous phases, applied in the field of materials, can solve problems such as complex synthesis steps, high cost, carbon material morphology, structure influence, etc., and achieve the effects of simple preparation conditions, easy operation, and good oxygen reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

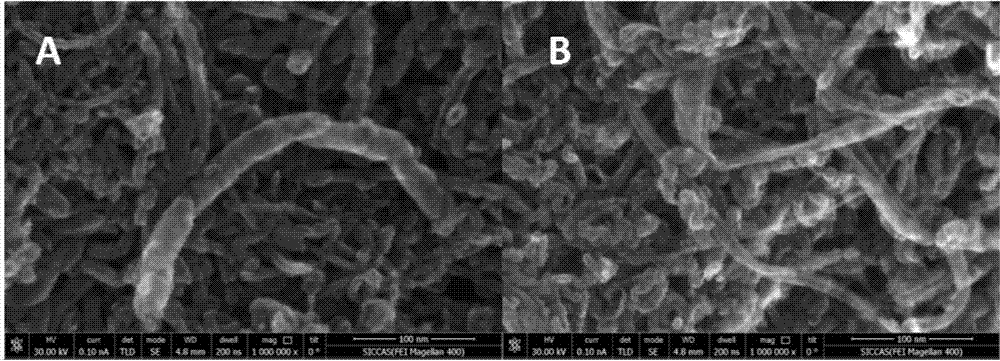

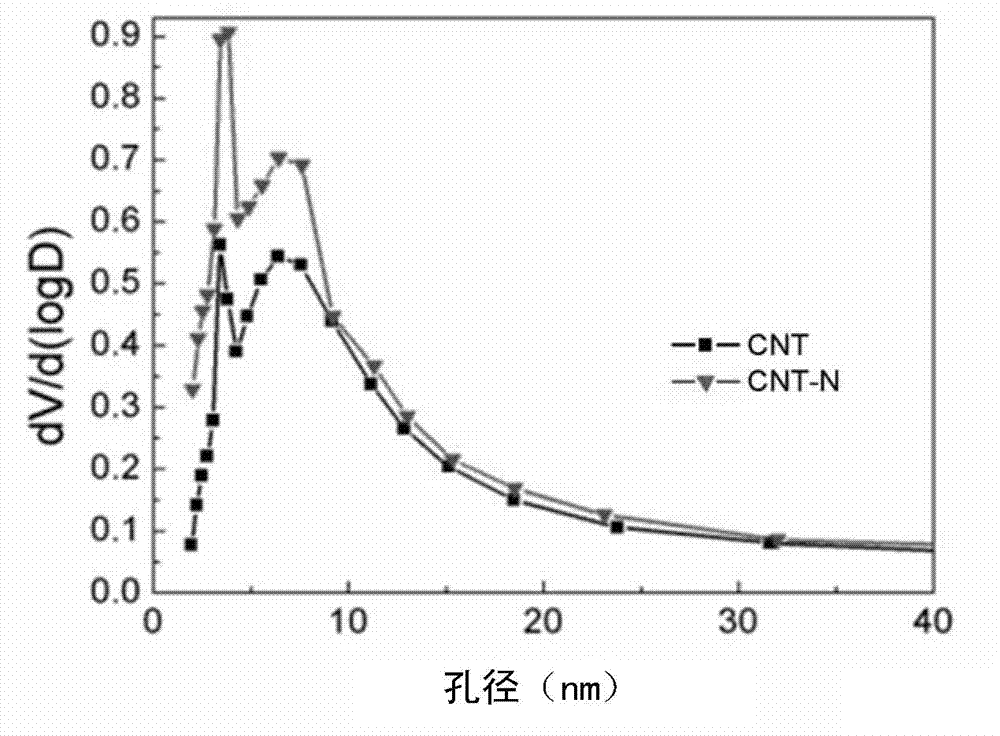

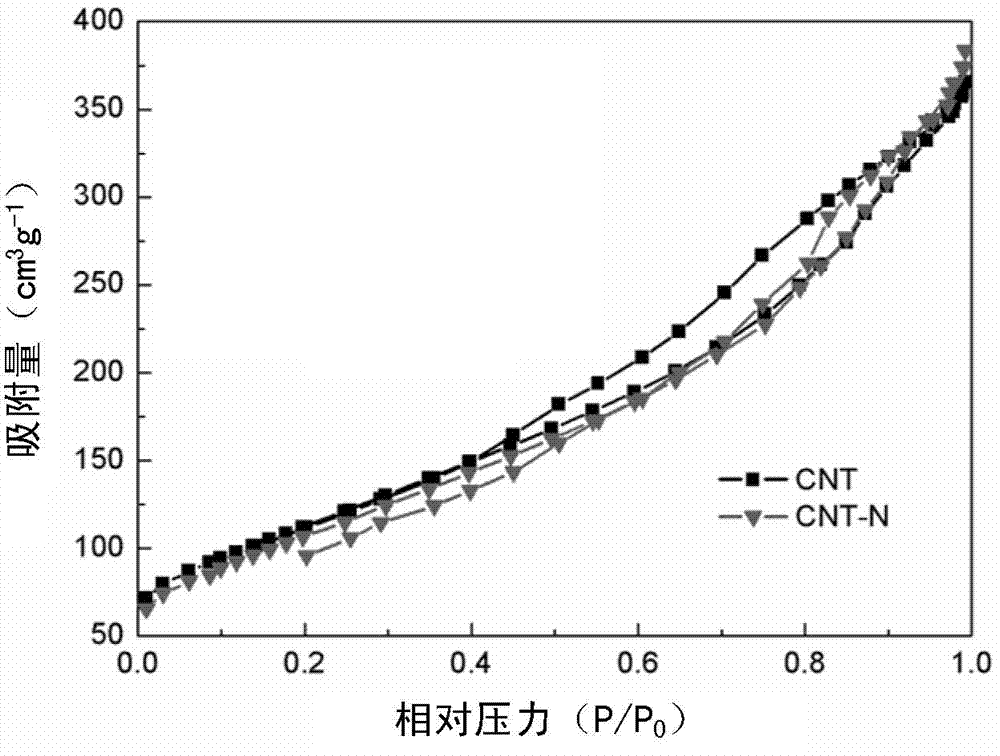

[0040] First, 0.1 g of carbon nanotubes was added to 35 ml of deionized water, and ultrasonically dispersed for 1 h. Then, 5 ml of ammonia water was added to the suspension of carbon nanotubes, and ultrasonic dispersion was continued for 1 h. Then the suspension was transferred to a 50ml hydrothermal kettle and placed in an oven at 180°C for 24h. After the reaction was completed, the suspension in the hydrothermal kettle was centrifuged and washed several times with deionized water. Finally, freeze-dry the obtained solid to obtain nitrogen-doped carbon nanotubes. Its element mapping diagram is as follows Figure 7 As shown, it shows that nitrogen atoms were successfully doped, and no other impurities were introduced. The SEM photos before (A) and after (B) of water heating are as follows figure 1 As shown, the pore size distribution is shown in figure 2 As shown, the nitrogen adsorption-desorption curve is as follows image 3 It can be seen from these figures that the n...

Embodiment 2

[0042] First, 0.1 g of mesoporous carbon was added to 40 ml of deionized water, and ultrasonically dispersed for 1 h. Then 2 g of boric acid was added to the suspension of mesoporous carbon, and ultrasonic dispersion was continued for 1 h. Then the suspension was transferred to a 50ml hydrothermal kettle and placed in an oven at 180°C for 24h. After the reaction was completed, the suspension in the hydrothermal kettle was centrifuged and washed several times with deionized water. Finally, the obtained solid is freeze-dried to obtain boron-doped mesoporous carbon. The boron-doped mesoporous carbon prepared by the method is consistent with the mesoporous carbon before the hydrothermal reaction in terms of specific surface area, pore size distribution, crystallinity and other properties. The CV curves of the as-prepared boron-doped mesoporous carbon in oxygen (solid line) or nitrogen (dashed line) saturated 0.1M KOH aqueous solution are as follows Figure 5 It can be seen that...

Embodiment 3

[0044] First, 0.1 g of carbon black was added to 30 ml of deionized water, and ultrasonically dispersed for 1 h. Then add 10ml1g ml to the suspension of carbon black -1 Sodium sulfide, and continue ultrasonic dispersion for 1h. Then the suspension was transferred to a 50ml hydrothermal kettle and placed in an oven at 180°C for 24h. After the reaction was completed, the suspension in the hydrothermal kettle was centrifuged and washed several times with deionized water. Finally, the obtained solid is freeze-dried to obtain sulfur-doped carbon black. The sulfur-doped carbon black prepared by the method is consistent with the carbon black before the hydrothermal reaction in terms of specific surface area, pore size distribution, crystallinity and the like. The CV curves of the prepared sulfur-doped carbon black in oxygen (solid line) or nitrogen (dashed line) saturated 0.1M KOH aqueous solution are as follows Image 6 It can be seen that it has good oxygen reduction performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com