Preparation method of kaolin/1-butyl-3-methyl bromide imidazole intercalated nanocomposite

A technology of imidazole methyl bromide and nanocomposite materials, applied in chemical instruments and methods, luminescent materials, silicon compounds, etc., can solve the problems of unfavorable large-scale production, small amount of one-time reaction, harsh reaction conditions, etc., and achieve good UV The effects of absorption performance, stable properties and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

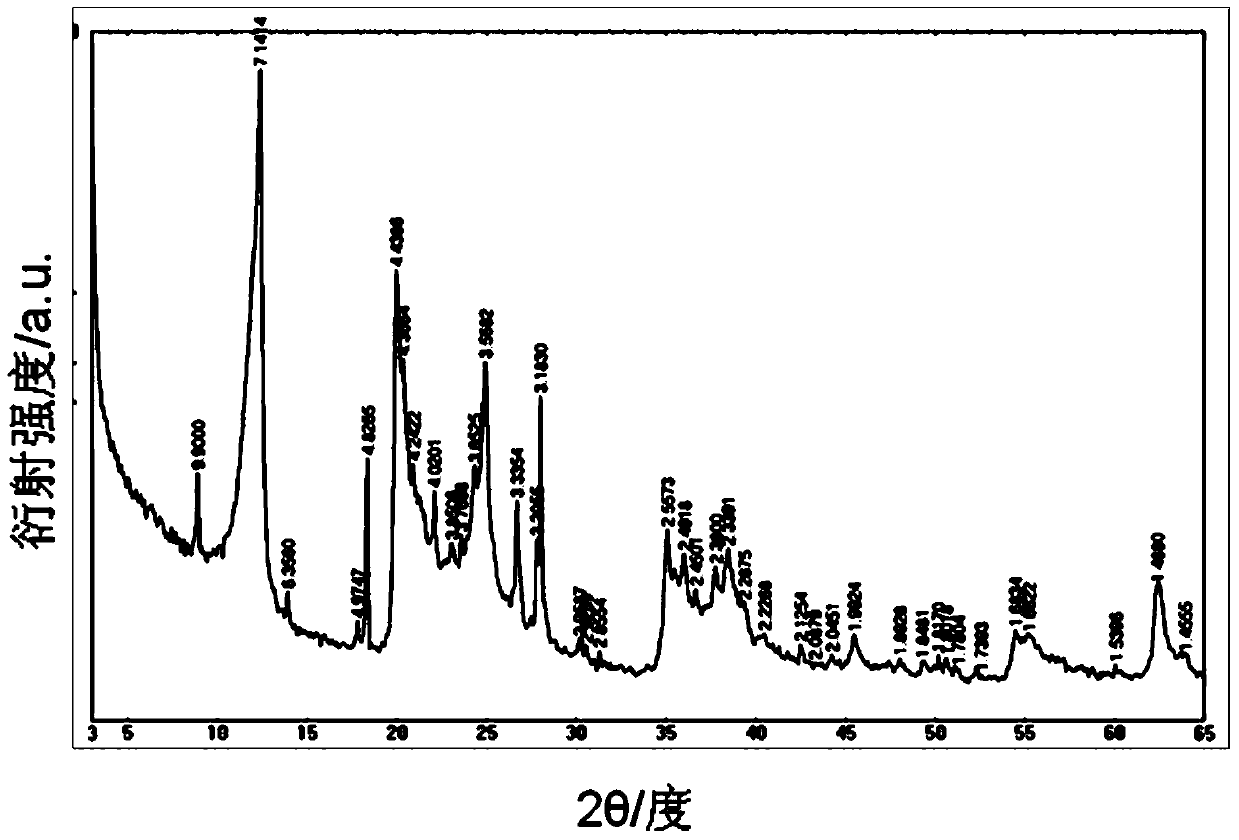

[0039] 1) Preparation of kaolin / dimethyl sulfoxide intercalation complex: Weigh 3 g of kaolin, add it to a mixed solution consisting of 45 ml dimethyl sulfoxide and 4.5 ml deionized water, and stir at 20 ° C with a magnetic stirrer to The reaction was carried out for 48 hours under stirring at a rotation speed of 300 rpm, and then the reaction product was filtered, washed, and dried at 60°C to obtain a kaolin / dimethyl sulfoxide intercalation complex;

[0040] 2) Preparation of kaolin / methanol intercalation complex: Weigh 2g of kaolin / dimethyl sulfoxide intercalation complex, add it to 24ml of methanol, stir at 20°C with a magnetic stirrer at a speed of 400 rpm React for 96 hours, centrifuge the reacted suspension at 1000 rpm for 15 minutes every 12 hours, discard the supernatant after centrifugation, replace with new methanol to continue the reaction, and discard the upper layer after the last centrifugation supernatant to obtain kaolin / methanol intercalation complex;

[0041...

Embodiment 2

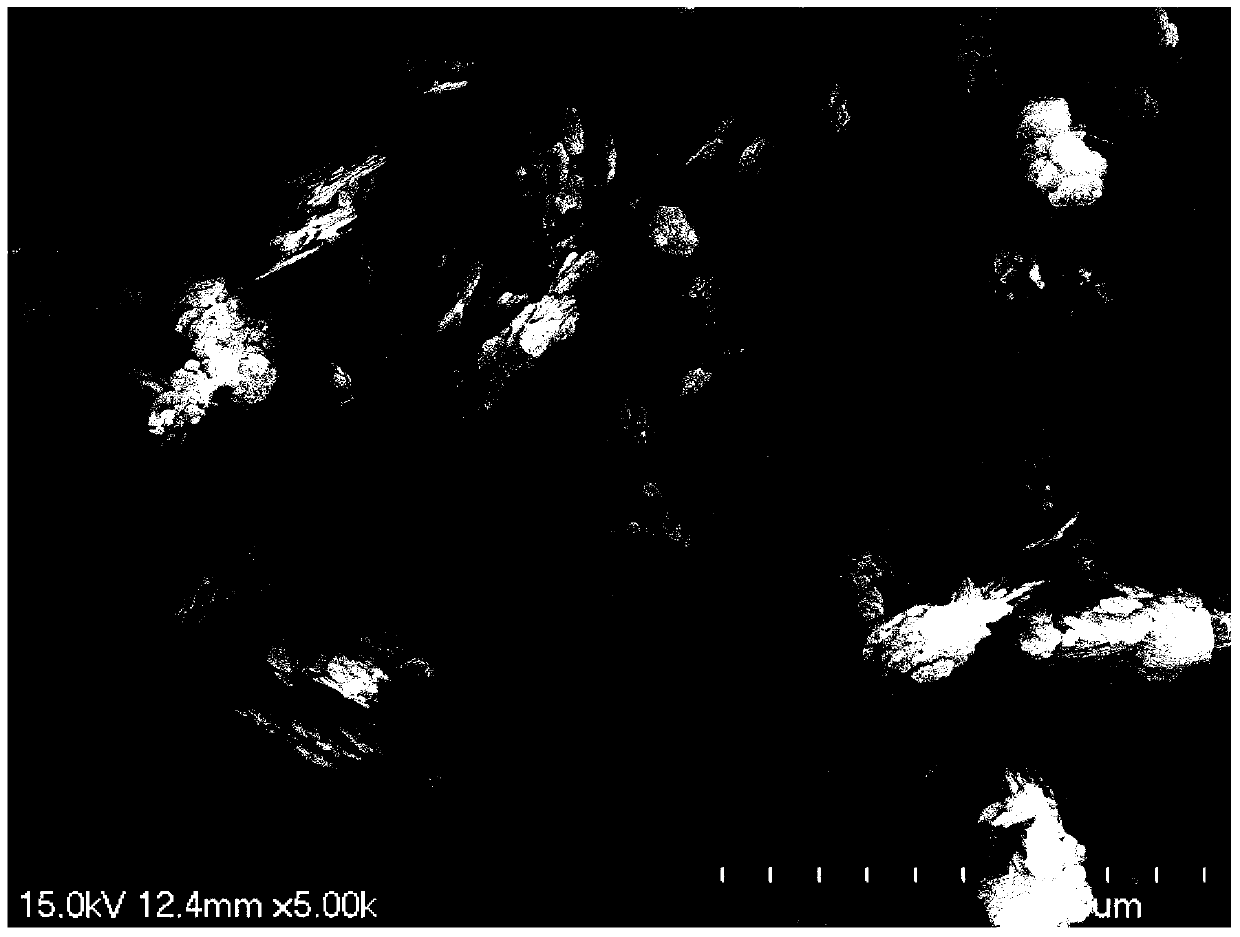

[0051] 1) Preparation of kaolin / dimethyl sulfoxide intercalation complex: Weigh 2g of soft kaolin from Lincang, Yunnan, and add it to a mixed solution consisting of 15ml dimethyl sulfoxide and 1.5ml deionized water. and react with a magnetic stirrer at a speed of 400 rpm for 72 hours, then filter the reaction product, wash it, and dry it at 50°C to obtain a kaolin / dimethyl sulfoxide intercalation complex. The Yunnan Lincang soft Al in kaolin 2 o 3 The mass percentage content is 37.7%, Fe 2 o 3 The mass percentage content is 0.19%, TiO 2 The mass percentage content is 0.13%, the whiteness is 86, and the average particle size is 10μm;

[0052] 2) Preparation of kaolin / methanol intercalation complex: weigh 2g of kaolin / dimethyl sulfoxide intercalation complex, add it to 30ml of methanol to obtain a mixed solution, and use a magnetic stirrer at 35°C with a rotation speed of 500 rpm React for 120 hours under stirring conditions per minute, centrifuge the reacted suspension at ...

Embodiment 3

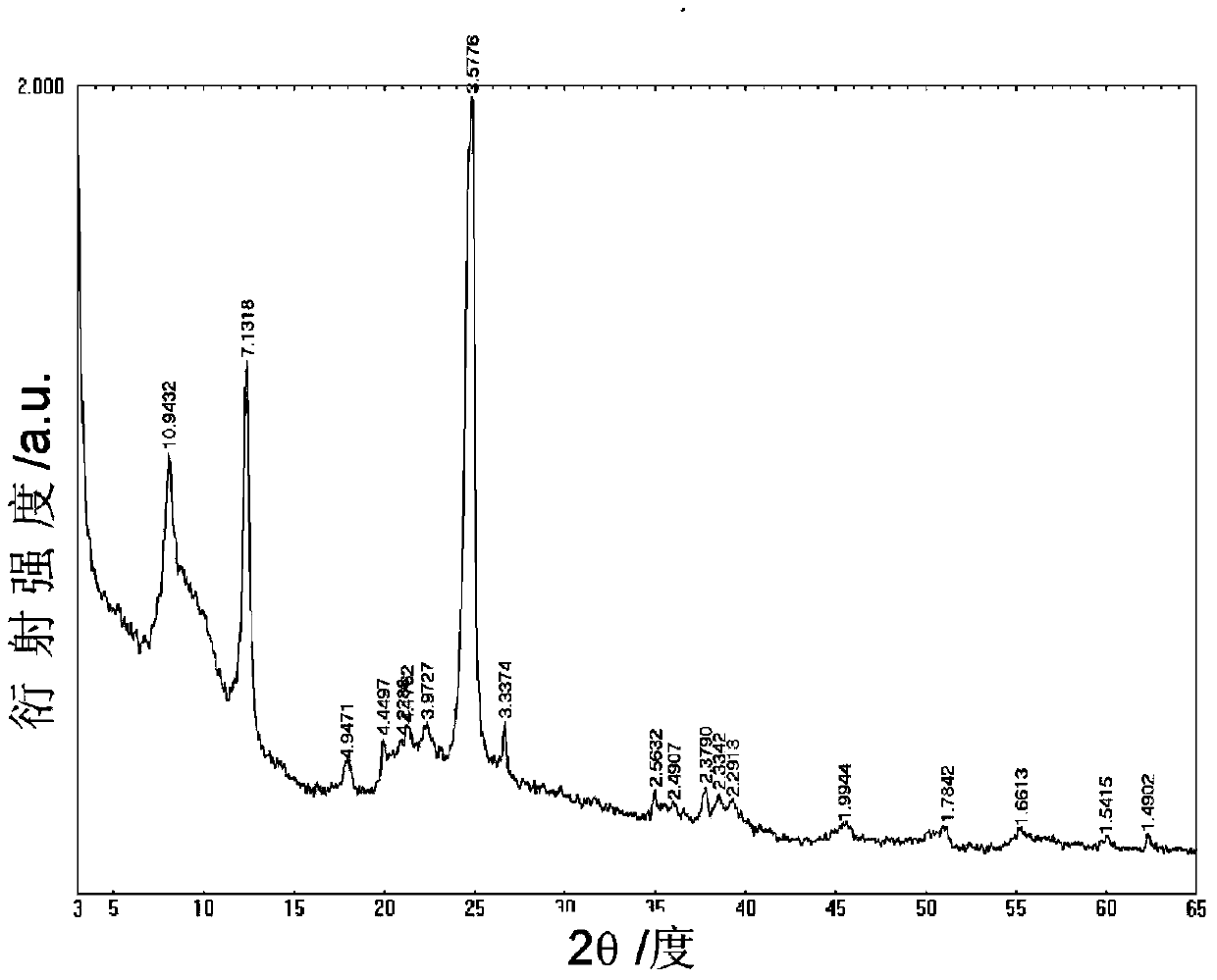

[0058]1) Preparation of kaolin / dimethyl sulfoxide intercalation complex: Weigh 4g of Yunnan Lincang soft kaolin, add it to a mixed solution consisting of 30ml dimethyl sulfoxide and 3ml deionized water, and heat at 35°C and React with a magnetic stirrer at 500 rpm for 96 hours, then filter the reaction product with suction, wash, and dry at 55°C to obtain a kaolin / dimethyl sulfoxide intercalation complex;

[0059] 2) Preparation of kaolin / methanol intercalation complex: Weigh 3g of kaolin / dimethyl sulfoxide intercalation complex, add it to 60ml of methanol, and react at 10°C with a magnetic stirrer at 400 rpm for 144 Every 24 hours, centrifuge the reacted suspension at 4000 rpm for 5 minutes, discard the supernatant after centrifugation, replace with new methanol and continue the reaction, and discard the supernatant after the last centrifugation , to obtain kaolin / methanol intercalation complex;

[0060] 3) Preparation of 1-butyl-3-methylimidazole bromide: Weigh 8.2g of N-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com