Organic/inorganic compound fertilizer containing chelating trace elements and production method thereof

A technology for chelating trace elements and production methods, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as poor application effects, uncertain types and quantities, and unsustainable fertilizer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

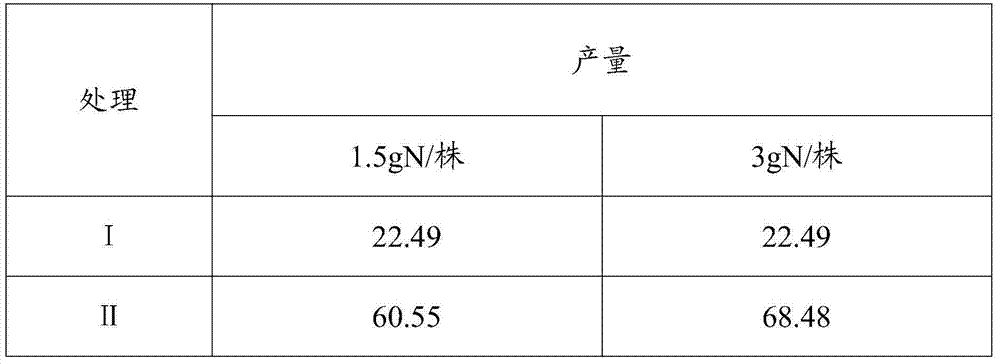

Embodiment 1

[0092] Embodiment 1: the preparation of the organic-inorganic compound fertilizer containing chelated trace elements of the present invention

[0093] The implementation steps of this embodiment are as follows:

[0094] A. Granulation material preparation

[0095] Grind the weathered coal, citric acid slag, furfural slag, diammonium phosphate, and potassium sulfate to a fineness above 60 mesh; The slag and the furfural slag are mixed to obtain an organic raw material; then the organic raw material, diammonium phosphate, and potassium sulfate are put into a drum granulator according to a weight ratio of 5:1:1 to obtain a granulated material;

[0096] B. Preparation of chelated trace element solution

[0097] Prepare 0.2mol / LEDTA-2Na and ZnSO respectively 4 with MnSO 4 solution, and then these solutions were mixed uniformly according to the volume ratio of 3:1:1, and then heated by steam for 20 minutes to obtain the chelated trace element solution I;

[0098] C. Preparatio...

Embodiment 2

[0111] Embodiment 2: the preparation of the organic-inorganic compound fertilizer containing chelated trace elements of the present invention

[0112] The implementation steps of this embodiment are as follows:

[0113] A. Granulation material preparation

[0114] Grind the weathered coal, citric acid slag, furfural slag, diammonium phosphate, and potassium sulfate to a fineness above 60 mesh; The slag and the furfural slag are mixed to obtain an organic raw material; then the organic raw material, diammonium phosphate, and potassium sulfate are put into a granulator according to a weight ratio of 5.0:1.5:1.5 to obtain a granulated material;

[0115] B. Preparation of chelated trace element solution

[0116] Prepare 0.2mol / LDTPA-5Na and ZnSO respectively 4 with MnSO 4 solution, and then these solutions were mixed uniformly according to the volume ratio of 2.5:1.0:1.0, and then heated by steam for 20 minutes to obtain the chelated trace element solution I;

[0117] C. Prep...

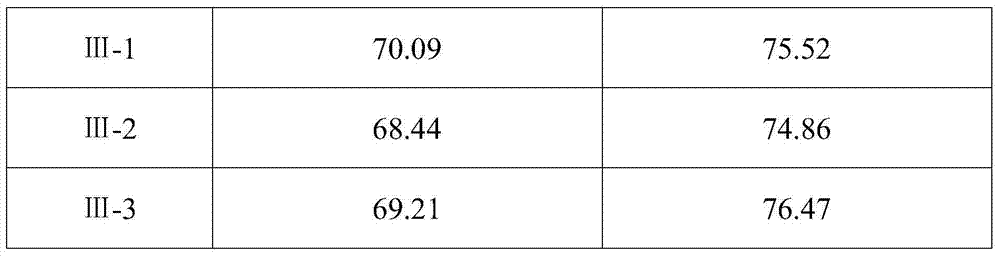

Embodiment 3

[0130] Embodiment 3: the preparation of the organic-inorganic compound fertilizer containing chelated trace elements of the present invention

[0131] The implementation steps of this embodiment are as follows:

[0132] A. Granulation material preparation

[0133] Grind the weathered coal, citric acid slag, furfural slag, monoammonium phosphate, and potassium sulfate to a fineness above 60 mesh; The slag and the furfural slag are mixed to obtain an organic raw material; then the organic raw material, monoammonium phosphate, and potassium sulfate are put into a granulator according to a weight ratio of 4.5:1.0:1.5 to obtain a granulated material;

[0134] B. Preparation of chelated trace element solution

[0135] Prepare 0.2mol / LEDTA-2Na and ZnSO respectively 4 with MnSO 4solution, and then these solutions were mixed uniformly according to the volume ratio of 2.0:1.0:0.5, and then heated by steam for 16 minutes to obtain the chelated trace element solution I;

[0136] C. P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com