Method for concentrating cefalexin through membrane method and enzyme concentration method

A technology of cephalexin and concentrated enzyme, which is applied in the direction of organic chemistry, etc., can solve the problems of environmental hazards and high energy consumption of extraction solvent, and achieve the effects of reducing human injury, low energy consumption, and easy modification and replacement of membrane components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

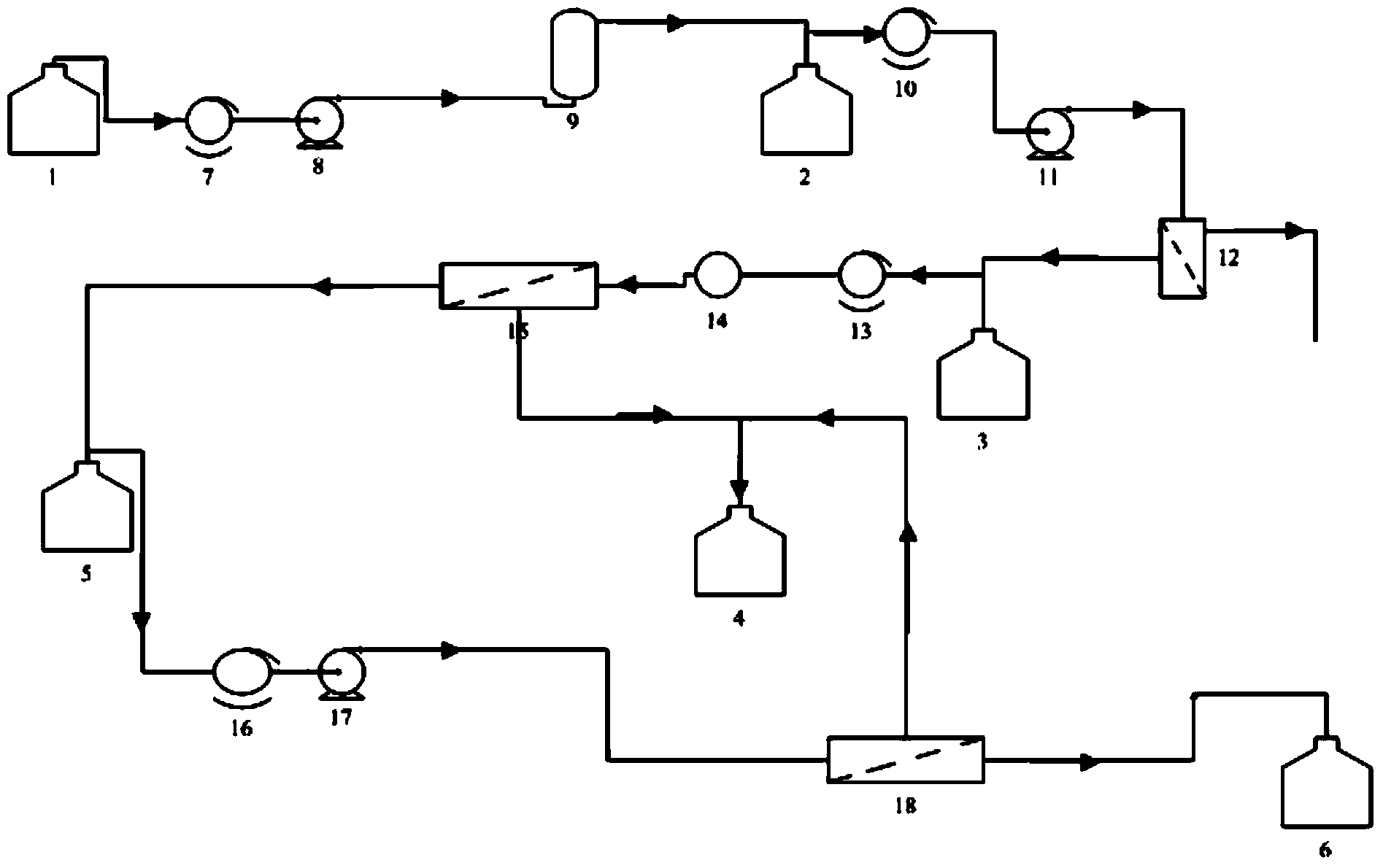

[0017] Specific embodiment one: the method for the present embodiment integrated membrane method and concentrated enzyme method to concentrate cephalexin, carry out according to the following steps:

[0018] 1. Place the cephalexin mother liquor prepared by the concentrated enzyme method in the mother liquor storage tank, and settle for 22h to 26h;

[0019] 2. Adopt a low-pressure pump to transfer the cephalexin mother liquor in the mother liquor storage tank, pass through the fine filter unit, and enter the fine filtrate storage tank;

[0020] 3. The cephalexin liquid in the fine filtrate storage tank is transported by a pump, and the obtained dialysate enters the ultrafiltrate storage tank through the ultrafiltration membrane unit;

[0021] 4. Use a high-pressure pump to transfer the dialysate obtained in step 3 to the first-level nanofiltration membrane unit with an operating pressure of 1.0MPa to 4.0MPa. After passing through the first-level nanofiltration membrane unit, t...

specific Embodiment approach 2

[0025] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the cephalexin mother liquor prepared by the concentrated enzymatic method described in step one is placed in the mother liquor storage tank, and settles for 24 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the ultrafiltration membrane described in step three is a kind of polymer ultrafiltration membrane or ceramic ultrafiltration membrane, and the form of the ultrafiltration membrane module is Hollow fiber or capillary. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com