A doped composite oxide-coated mica pearlescent composite pigment and its preparation

A technology of composite oxides and composite pigments, applied in the direction of inorganic pigment treatment, fibrous fillers, chemical instruments and methods, etc., can solve problems such as complex processes and multi-layer coatings, and achieve simple processes, improved performance, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mica pretreatment: 70-80°C water bath temperature, 5% hydrochloric acid to mica liquid-solid mass ratio of 20, stir for 30 minutes, wash and dry. Take 30g of pretreated mica (with a particle size of 5-25μm) to prepare 10wt% mica slurry.

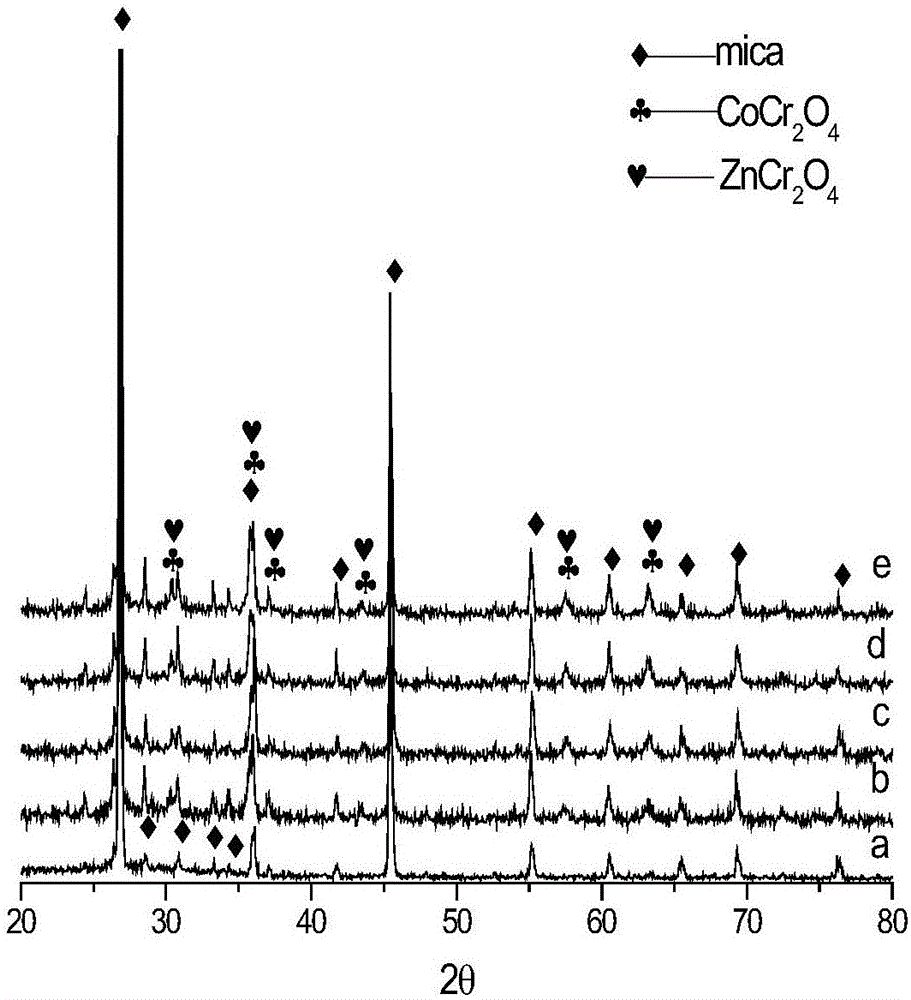

[0028] (2) Composite pigment Co .0.9 Zn 0.1 Cr 2 o 4 / Mica precursor preparation, preparation of cobalt chromium zinc ion solution: 5.24gCo(NO 3 ) 2 .6H 2 O, 0.59gZn(NO 3 ) 2 .6H 2 O and 16gCr(NO 3 ) 3 .9H 2 O was added to 100ml of deionized water to form a mixed solution; 8g of sodium hydroxide was dissolved in water to form a solution equal in volume to the cobalt-chromium-zinc ion solution. Heat the mica slurry in a water bath to 70°C, under the condition of mechanical stirring at 300rmp, slowly add the cobalt-chromium-zinc solution and the sodium hydroxide solution dropwise at the same time, the dropping time is 1.5h, the dropping is completed, adjust the pH to 8.5-9.5, and mature for half an hour. After washing w...

Embodiment 2

[0031] (1) Mica pretreatment: 70-80°C water bath temperature, 5% hydrochloric acid to mica liquid-solid mass ratio of 20, stir for 30 minutes, wash and dry. Take 30g of pretreated mica (with a particle size of 5-25μm) to prepare 10wt% mica slurry.

[0032] (2) Composite pigment Co 0.7 Zn 0.3 Cr 2 o 4 / Mica precursor preparation, preparation of cobalt chromium zinc ion solution: 4.07gCo(NO 3 ) 2 .6H 2 O, 1.78gZn(NO 3 ) 2 .6H 2 O and 16gCr(NO 3 ) 3 .9H 2 O was added to 100ml of deionized water to form a mixed solution; 8g of sodium hydroxide was dissolved in water to form a solution equal in volume to the cobalt-chromium-zinc ion solution. Heat the mica slurry in a water bath to 70°C, under the condition of mechanical stirring at 300rmp, slowly add the cobalt-chromium-zinc solution and the sodium hydroxide solution dropwise at the same time, the dropping time is 1.5h, the dropping is completed, adjust the pH to 8.5-9.5, and mature for half an hour. After washing wit...

Embodiment 3

[0035] (1) Mica pretreatment: 60-70°C water bath temperature, 2% hydrochloric acid to mica liquid-solid mass ratio of 20, stir for 30 minutes, wash and dry. Take 30g of pretreated mica (with a particle size of 5-25μm) to prepare 10wt% mica slurry.

[0036] (2) Composite pigment Co 0.5 Zn 0.5 Cr 2 o 4 / Mica precursor preparation, preparation of cobalt chromium zinc ion solution: 2.91gCo(NO 3 ) 2 .6H 2 O, 2.97gZn(NO 3 ) 2 .6H 2 O and 16gCr(NO 3 ) 3 .9H 2 O was added to 100ml of deionized water to form a mixed solution; 8g of sodium hydroxide was dissolved in water to form a solution equal in volume to the cobalt-chromium-zinc ion solution. Heat the mica slurry in a water bath to 70°C, under the condition of mechanical stirring at 300rmp, slowly add the cobalt-chromium-zinc solution and the sodium hydroxide solution dropwise at the same time, the dropping time is 1.5h, the dropping is completed, adjust the pH to 8.5-9.5, and mature for half an hour. After washing wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com