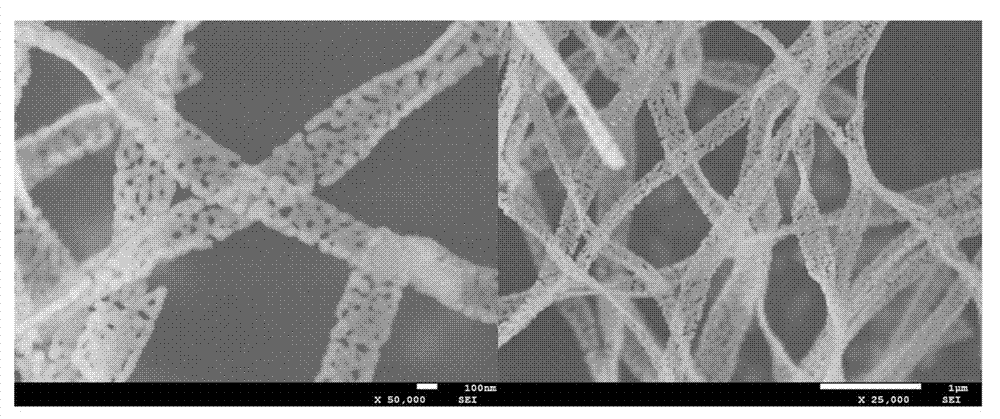

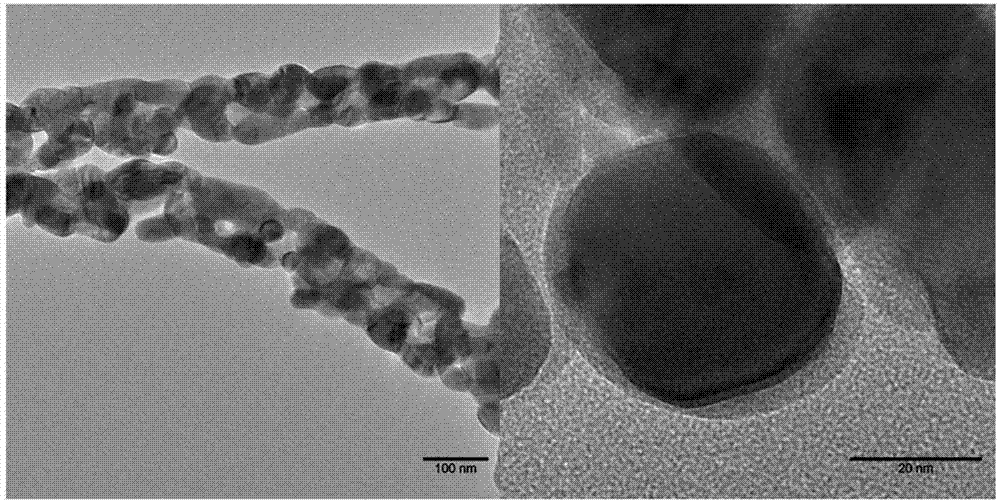

Synthetic method of strip porous lanthanum ferrite nano fibers

A nanofiber, synthesis method technology, applied in fiber processing, filament/thread forming, textile and papermaking, etc., can solve the problem of reducing the performance of catalysis and adsorption, easy deactivation of lanthanum ferrite nanoparticles, not very high specific surface area, etc. It can improve the performance of catalysis and adsorption, increase the specific surface area, and achieve the effect of large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 0.5g Fe(NO 3 ) 3 9H 2 O and La(NO 3 ) 3 ·6H 2 O was dissolved in a mixed solution of 1 mL ethanol and 1 mL acetic acid, and stirred at room temperature for 1 h with a magnetic stirrer to form a mixed solution A. Then 2 g of polyvinylpyrrolidone was dissolved in 5 mL of ethanol, and stirred at room temperature for 2 h to form solution B. Finally, the mixed solution A was slowly added to the solution B with a dropping funnel, and stirred at room temperature for 6 h to form a precursor solution C. Add the precursor solution into the syringe, connect the negative electrode of the high-voltage power supply to the receiver, and connect the positive electrode to the stainless steel needle of the syringe for spinning. The collected composite fibers are dried and calcined.

Embodiment 2

[0023] 0.4 g of C with a molar ratio of 1:1 15 h 21 FeO 6 and La(CH 3 COO) 3 1.5H 2 O was dissolved in 2 mL of acetic acid and stirred at room temperature for 1 h with a magnetic stirrer to form a mixed solution A. Then 1.75g of polyvinylpyrrolidone was dissolved in 5mL of ethanol, and stirred at room temperature for 2h to form solution B. Finally, the mixed solution A was slowly added to the solution B with a dropping funnel, and stirred at room temperature for 6 h to form a precursor solution C. Add the precursor solution into the syringe, connect the negative electrode of the high-voltage power supply to the receiver, and connect the positive electrode to the stainless steel needle of the syringe for spinning. The collected composite fibers are dried and calcined.

Embodiment 3

[0025] 0.6g of C with a molar ratio of 1:1 15 h 21 FeO 6 and La(NO 3 ) 3 ·6H 2 O was dissolved in 2 mL of distilled water and stirred at room temperature for 1 h with a magnetic stirrer to form a mixed solution A. Then 2.25 g of polyvinylpyrrolidone was dissolved in 5 mL of ethanol, and stirred at room temperature for 2 h to form solution B. Finally, the mixed solution A was slowly added to the solution B with a dropping funnel, and stirred at room temperature for 6 h to form the precursor solution C. Add the precursor solution into the syringe, connect the negative electrode of the high-voltage power supply to the receiver, and connect the positive electrode to the stainless steel needle of the syringe for spinning. The collected composite fibers are dried and calcined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com