IGBT device and manufacturing method thereof

A device, N-type technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of increasing IGBT device turn-off time, reducing forward voltage drop and turn-off time, and unsatisfactory IGBT device performance. and other problems, to achieve the effect of optimizing switching characteristics, increasing turn-off speed, and good turn-on and turn-off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

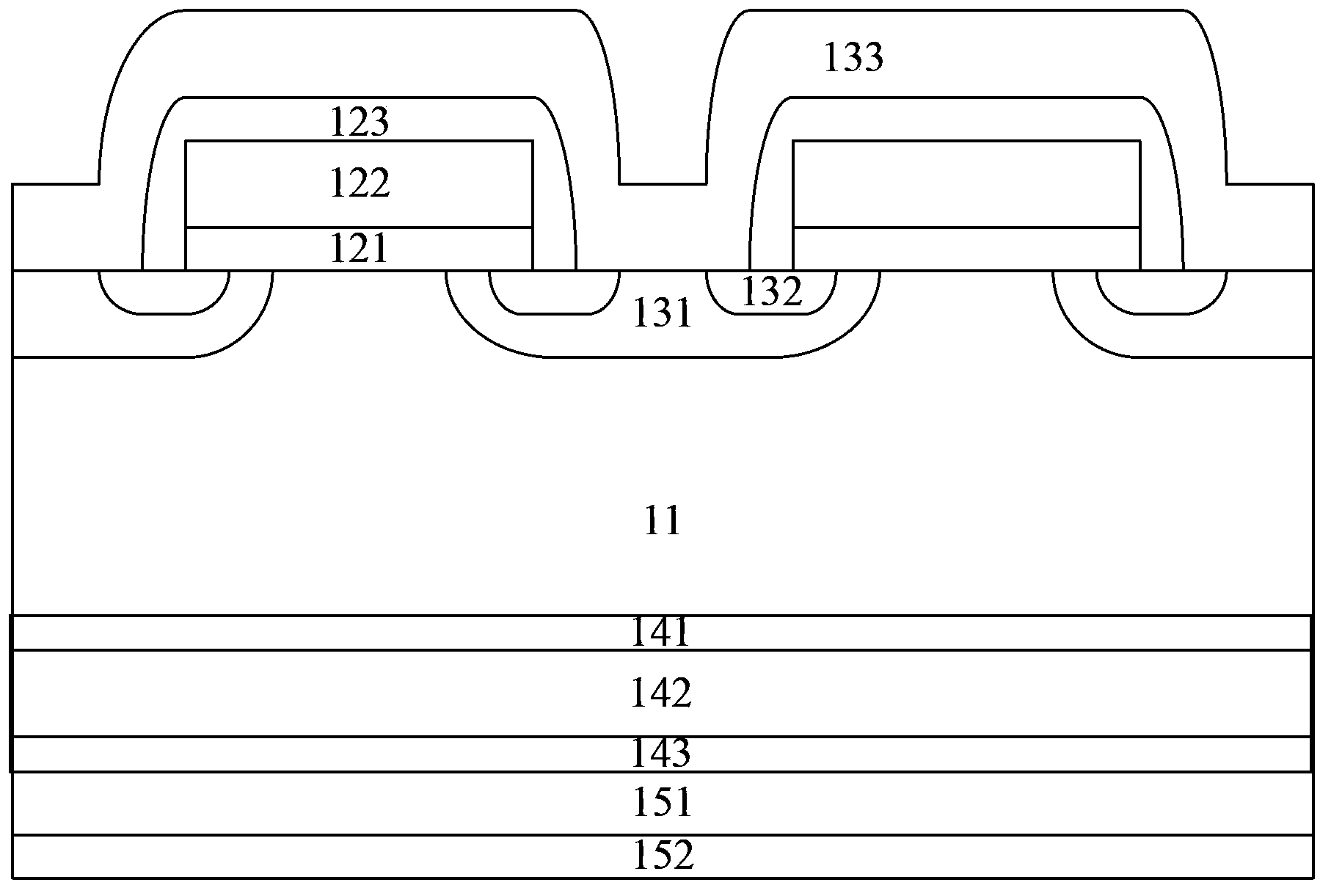

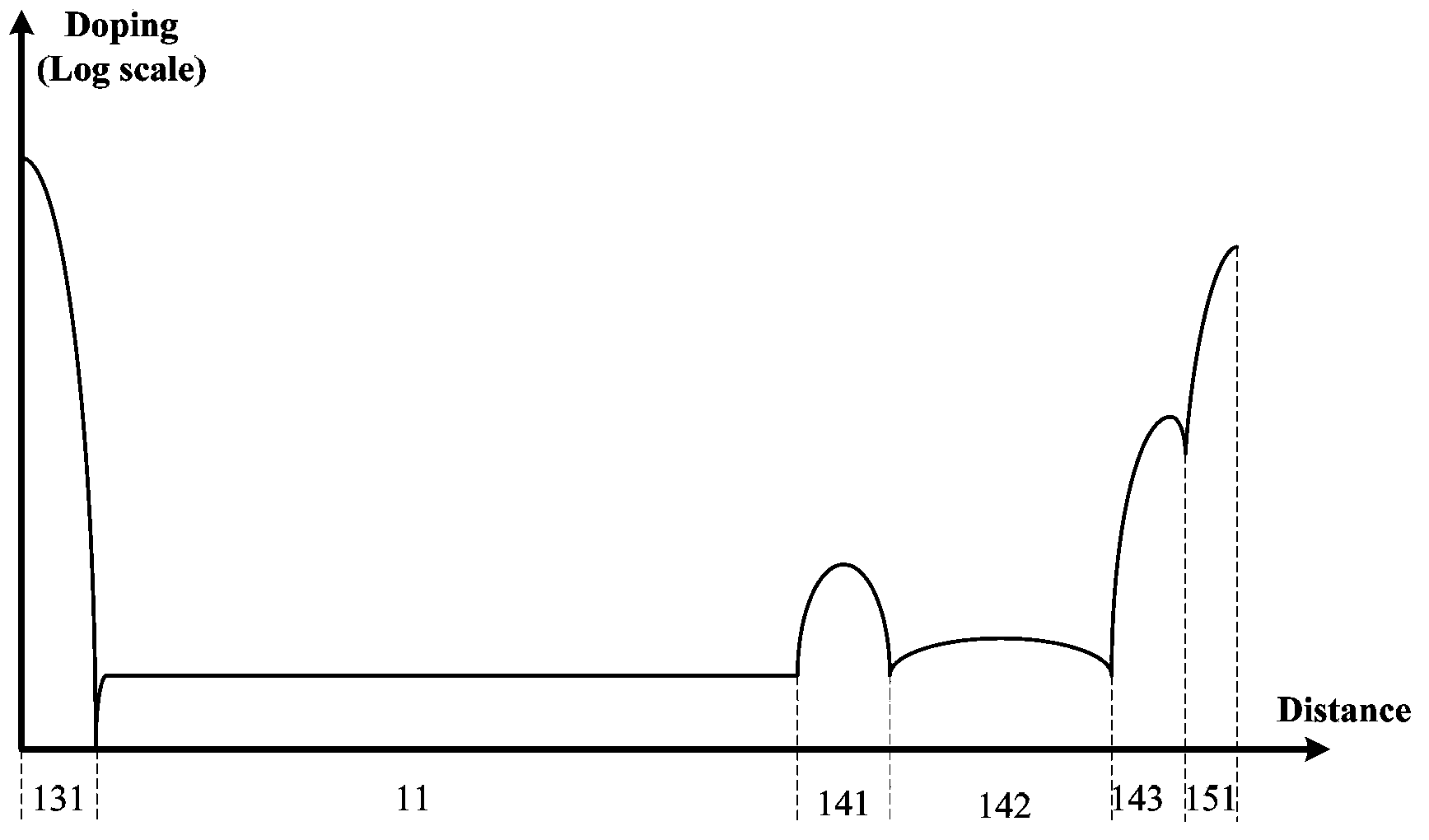

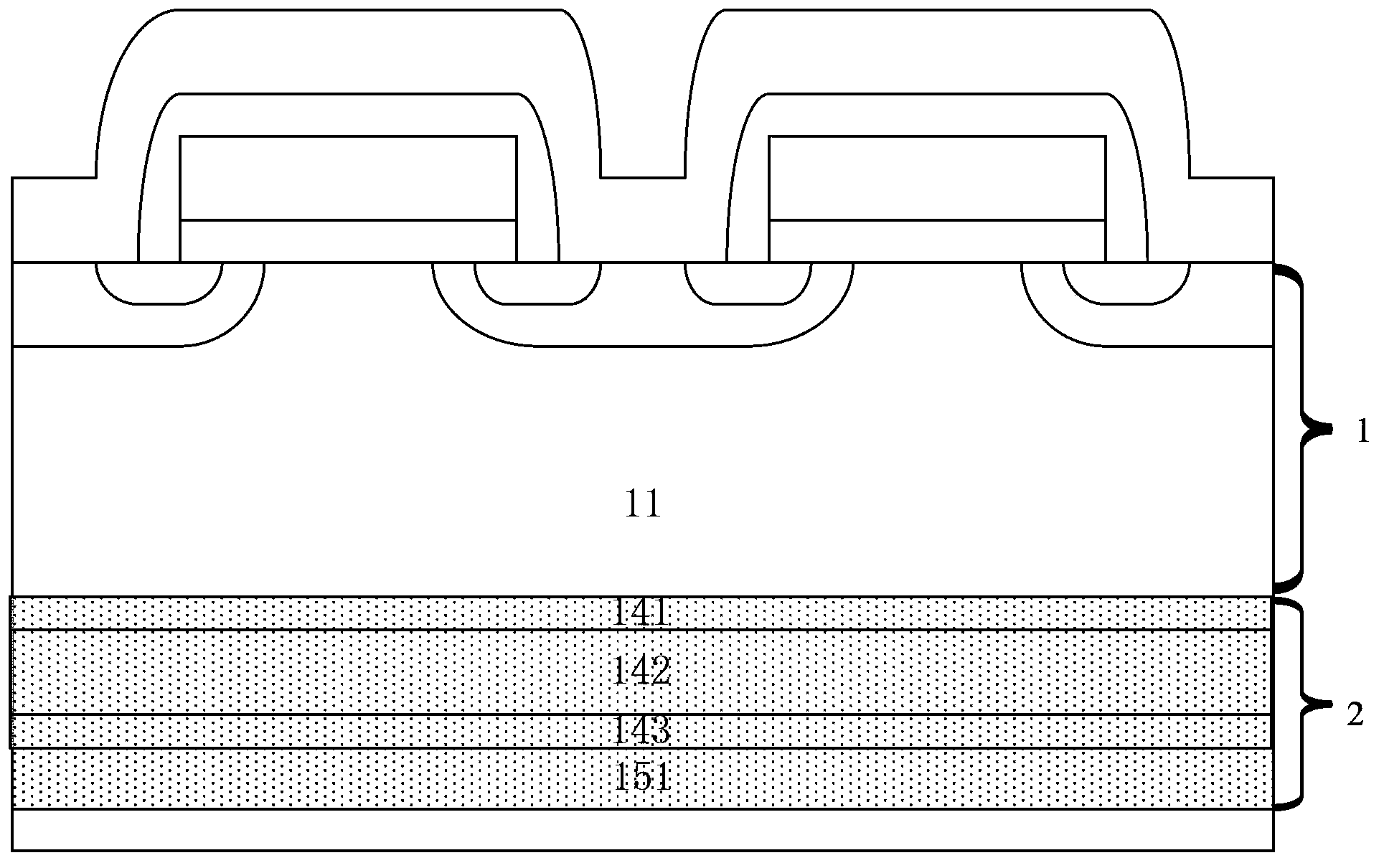

[0066] As mentioned in the background art, the performance of existing IGBT devices is not ideal. The inventors found that, for an electric field blocking IGBT device provided with an N-type buffer layer, in its blocking state, the electric field of the device is mainly distributed in the N-type base region, and between the N-type base region and the N-type At the junction of the N-type buffer layer, the electric field intensity distribution at the interface is determined by the doping concentration at the interface, and the voltage drop of the N-type buffer layer is determined by the thickness and doping concentration of the N-type buffer layer; in the N-type buffer layer and the collector structure At the collector region interface, the doping concentration of the collector region and the N-type buffer layer determines the injection efficiency of the device, and increasing the doping concentration of the N-type buffer layer will reduce the injection efficiency of the back col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com