Pelvic floor repairing sheet

A patch and pelvic floor technology, which is applied in the field of patch in the field of biomedical technology, can solve the problems of poor capillary permeability, failure to provide directionality for fibroblast growth, etc., and achieve good biocompatibility and good tissue compliance , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

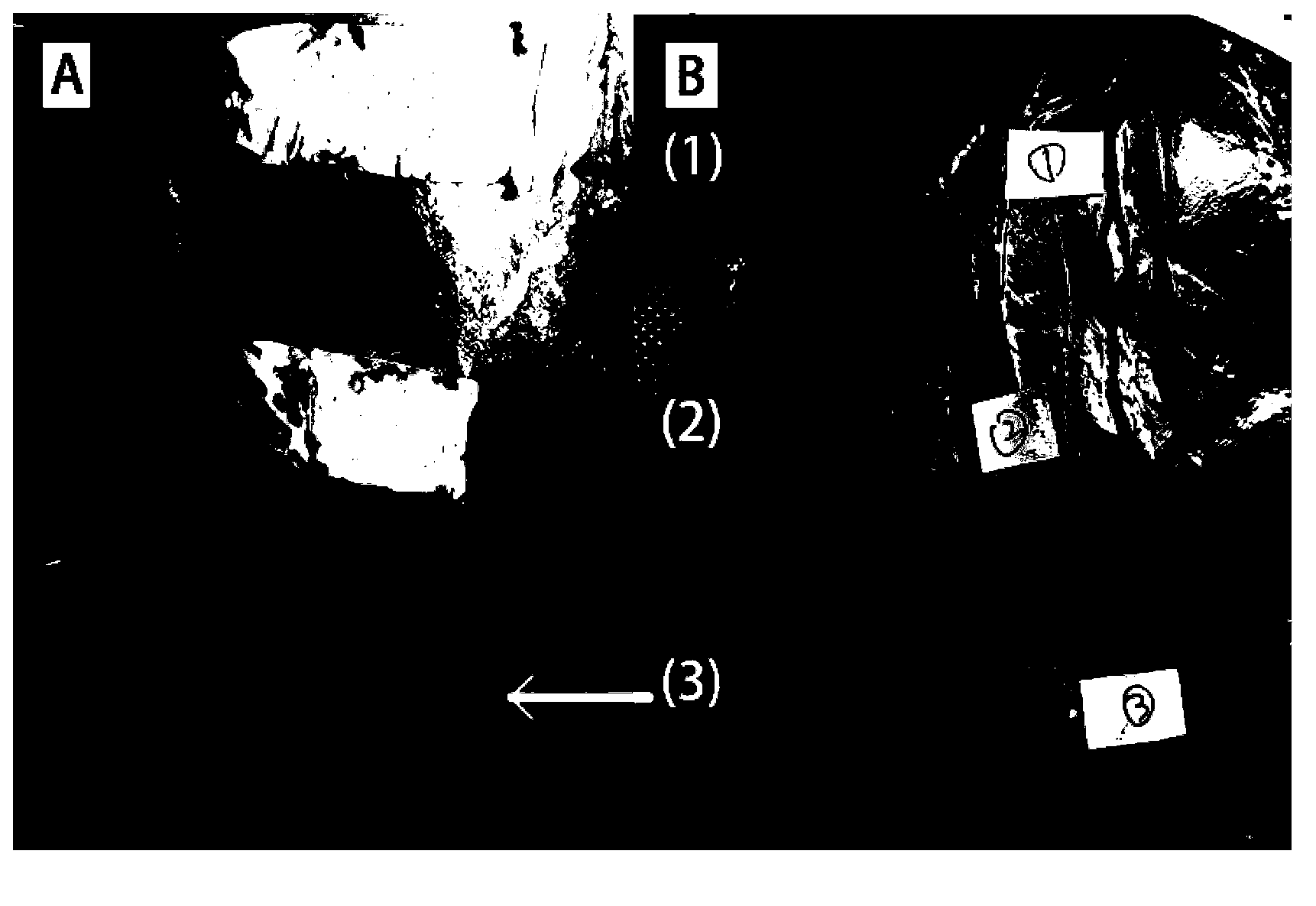

[0074] Example 1 (preparation of double-layer electrospun membrane)

[0075] Polyvinylidene fluoride (PVDF) was dissolved in dimethylacetamide (DMAc) solvent to form a homogeneous solution with a concentration of 20 g / 100 mL of polyvinylidene fluoride.

[0076] Then put the above solution into the electrospinning syringe, adjust the speed of the micro syringe pump to 3 ml / hour, adjust the voltage of the high voltage generator to 22 kV, and adjust the receiving distance of the receiving device to 20 cm. The receiving device uses a rotating roller, the moving speed of the electrospinning needle is 10 cm / s, the rotating speed of the receiving roller is 4000 cycles / min, and the two needles are electrospun at the same time for 8 hours, thereby preparing the oriented first fiber layer. Next, the rotational speed was lowered to 80 revolutions per minute, and two needles were also used to perform electrospinning for 8 hours, thereby preparing a non-oriented second fiber layer. After ...

Embodiment 2

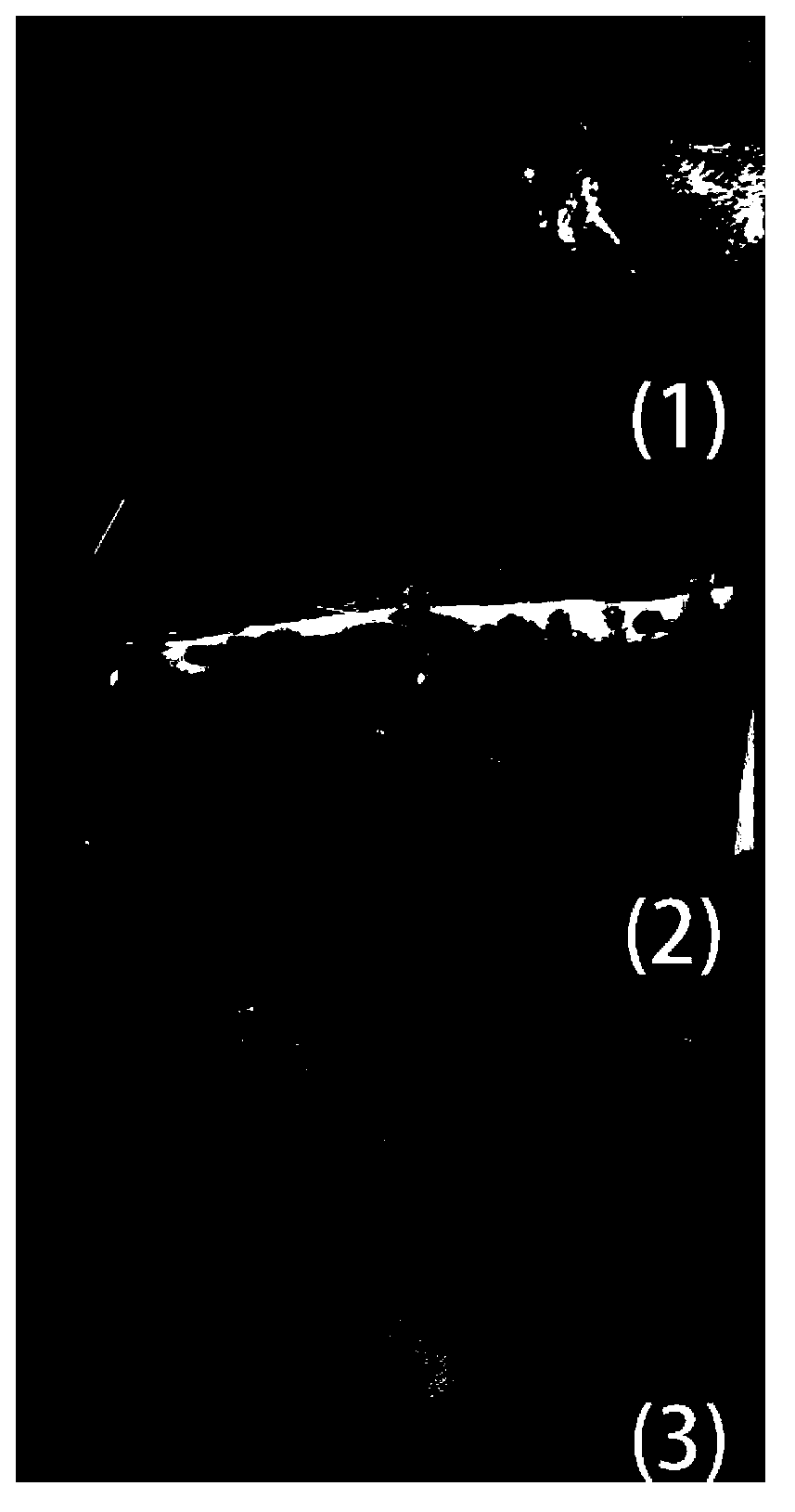

[0077] Embodiment 2 (preparation of three-layer fiber membrane)

[0078] Polyglycolic acid and polylactic acid were respectively dissolved in hexafluoroisopropanol (HFIP) to obtain solution a, wherein the concentration of polyglycolic acid was 8g / 100mL, and the concentration of polylactic acid was 10g / 100mL.

[0079] Dissolve polyglycolic acid, polylactic acid, and the drug Panax notoginseng in hexafluoroisopropanol to obtain solvent b, wherein the concentration of polyglycolic acid is 6g / 100mL, the concentration of polylactic acid is 8g / 100mL, and the drug Panax notoginseng is 10g / 100mL. 100mL.

[0080] Then put the above solution a into the electrospinning syringe, adjust the speed of the micro syringe pump to 2 ml / hour, adjust the voltage of the high voltage generator to 15 kV, and adjust the receiving distance of the receiving device to 20 cm. The receiving device uses a rotating roller, the moving speed of the electrospinning needle is 3 cm / s, the rotating speed of the r...

Embodiment 3

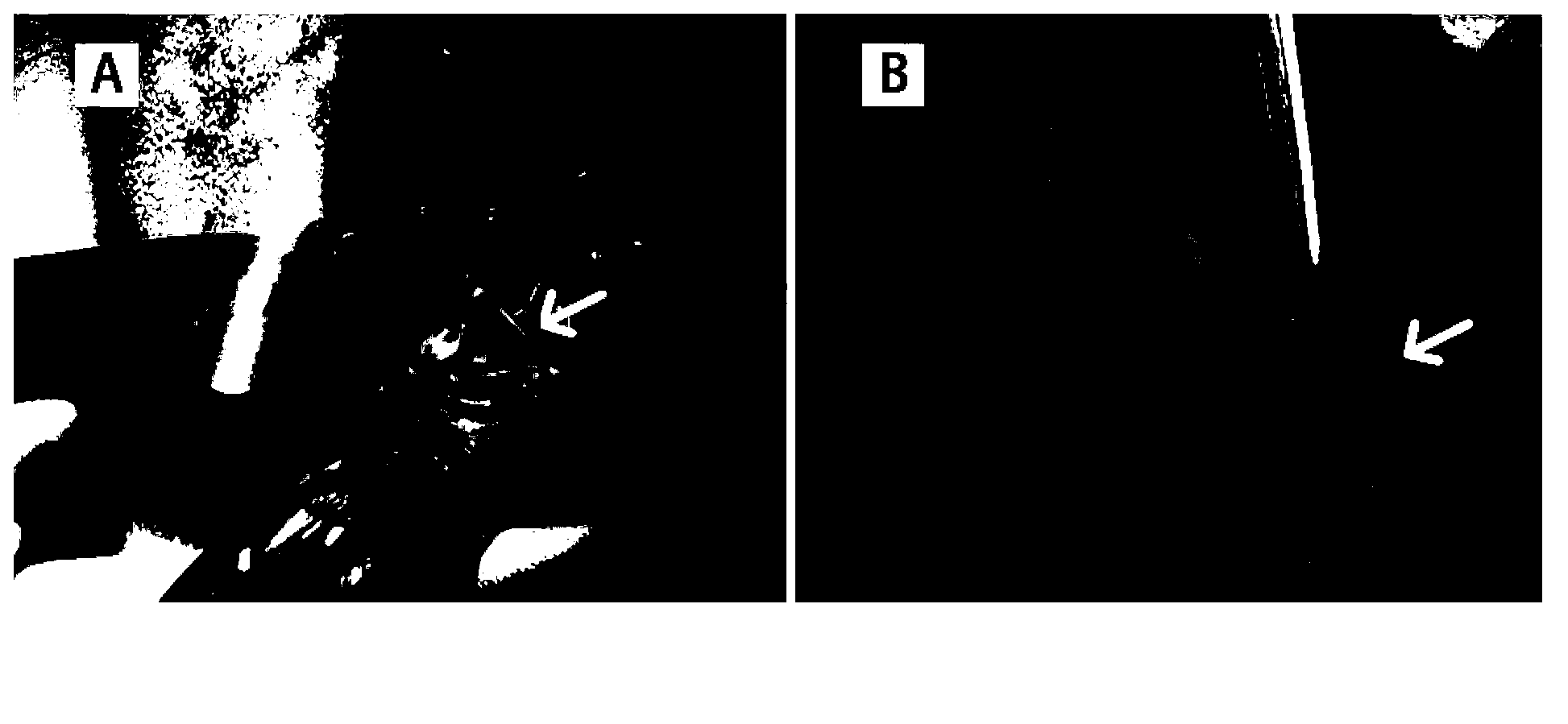

[0081] Embodiment 3 (preparation of three-layer fiber membrane)

[0082] Dissolve high polymer polycarbonate polyurethane (PCU) in dimethylformamide (DMF) to obtain solution a, in which the concentration of PCU is 12g / 100mL.

[0083] Dissolve PCU and drug ampicillin in DMAc to obtain solution b, wherein the concentration of PCU is 12g / 100mL, and the concentration of drug ampicillin is 15g / 100mL.

[0084] Then put the above solution a into the electrospinning syringe, adjust the speed of the micro-injection pump to 12 ml / hour, adjust the voltage of the high-voltage generator to 42 kV, and adjust the receiving distance of the receiving device to 15 cm. The receiving device uses a rotating roller, the moving speed of the electrospinning needle head is 26 cm / s, the rotating speed of the receiving roller is 4000 cycles / min, and the two needles are electrospun at the same time for 2 hours, thereby preparing the oriented first fiber layer. Next, replace the solution in the electrosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com