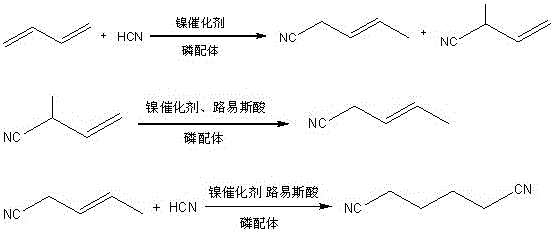

Method for inhibiting the degradation of phosphorus-containing ligands in the synthesis of adiponitrile by butadiene method

A technology of adiponitrile and butadiene, which is applied in the field of inhibiting the degradation of phosphorus-containing ligands, can solve the problem of increasing the cost of raw materials for the synthesis of adiponitrile by butadiene method, reducing the separation recovery rate of zero-valent nickel catalyst and phosphorus-containing ligands, etc. problems, achieve the effect of no influence on conversion rate and selectivity, reduce raw material cost, and improve separation recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

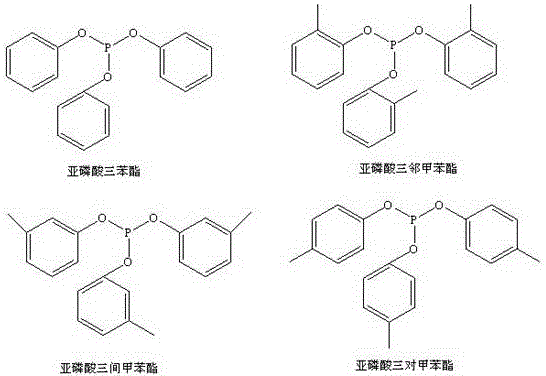

Embodiment 1

[0024] Add 2-methyl-3-butenenitrile, tri-o-cresyl phosphite, zero-valent nickel catalyst, aluminum chloride and triethylamine to the isomerization reaction in a molar ratio of 30:5:1:1:0.5 In the reactor, control the reaction pressure to 0.1Mpa, the reaction temperature to 100°C, and keep warm for 12 hours; after the reaction, the product 3-pentenenitrile (3PN) and unreacted 2-methyl-3-butene are separated Nitrile (2M3BN). The degradation rate of phosphorus-containing ligands in the system was measured by high performance liquid chromatography (HPLC) to be 1.2%, the conversion rate of 2M3BN was 95%, and the selectivity of 3PN was 95%.

Embodiment 2

[0026] Add 2-methyl-3-butenenitrile, triphenyl phosphite, zero-valent nickel catalyst, zinc chloride and diethylamine to the isomerization reactor in a molar ratio of 80:10:1:30:0.2 , control the reaction pressure at 0.1Mpa, the reaction temperature at 110°C, and keep warm for 12 hours; after the reaction, the product 3-pentenenitrile (3PN) and unreacted 2-methyl-3-butenenitrile ( 2M3BN). The degradation rate of phosphorus-containing ligands in the system was measured by high performance liquid chromatography (HPLC) to be 2.1%, the conversion rate of 2M3BN was 96%, and the selectivity of 3PN was 95%.

Embodiment 3

[0028] Add 2-methyl-3-butenenitrile, triphenyl phosphite, zero-valent nickel catalyst, zinc sulfate, and N,N-dimethylaniline in a molar ratio of 100:15:1:50:0.15 to the isomer In the chemical reactor, the reaction pressure is controlled at 0.1Mpa, the reaction temperature is 100°C, and the reaction is held for 8 hours; after the reaction, the product 3-pentenenitrile (3PN) and unreacted 2-methyl-3- Acrylonitrile (2M3BN). The degradation rate of phosphorus-containing ligands in the system was measured by high performance liquid chromatography (HPLC) to be 3%, the conversion rate of 2M3BN was 97%, and the selectivity of 3PN was 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com