A method for synergistic reduction of pyrolusite by low-carbon organic matter

A technology for organic matter and pyrolusite, applied in the field of pyrolusite reduction, can solve the problems of difficult waste liquid treatment, low current efficiency, anode plate corrosion, etc., to reduce the concentration of incomplete oxidation products, improve the leaching rate, and complete the reduction reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

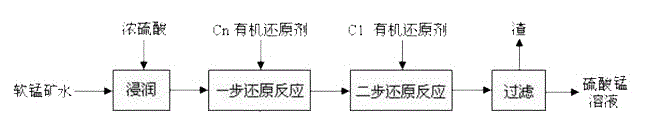

Method used

Image

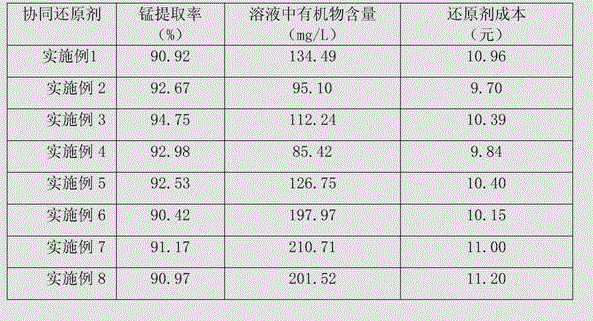

Examples

Embodiment 1

[0029] 1. Raw material composition and weight:

[0030] 10Kg pyrolusite, 18Kg concentrated sulfuric acid, 90Kg water, 1.8Kg formic acid, 0.8Kg oxalic acid.

[0031] 2. Preparation method:

[0032] Take 10Kg of pyrolusite in the reaction kettle, add 90Kg of water, stir and heat to 90-95°C, stop heating, slowly add 18Kg of concentrated sulfuric acid, then continue stirring for 20 minutes, then add 0.8Kg of oxalic acid, and react at 90-95°C for 1.5 Hour, finally add formic acid 1.8Kg, continue stirring reaction 2 hours, filter, obtain manganese sulfate solution. Determination of manganese content in manganese sulfate solution by conventional methods, calculation of manganese leaching rate, while using high performance liquid phase determination of organic content.

Embodiment 2

[0034] 1. Raw material composition and weight:

[0035] 10Kg pyrolusite, 14Kg concentrated sulfuric acid, 95Kg water, 1.5Kg formaldehyde, 0.6Kg oxalic acid, 1.0Kg glucose.

[0036] 2. Preparation method:

[0037] Take 10Kg of pyrolusite in a reaction kettle, add 95Kg of water, stir and heat to 90-95°C, then stop heating, slowly add 14Kg of concentrated sulfuric acid, then continue stirring for 30 minutes, add glucose 1.0Kg, oxalic acid 0.6Kg, 90-95 The reaction was carried out at ℃ for 2 hours, and finally 1.5Kg of formaldehyde was added, and the reaction was continued to stir for 3 hours, and filtered to obtain a manganese sulfate solution. Determination of manganese content in manganese sulfate solution by conventional methods, calculation of manganese leaching rate, while using high performance liquid phase determination of organic content.

Embodiment 3

[0039] 1. Raw material composition and weight:

[0040] 10Kg of pyrolusite, 22Kg of concentrated sulfuric acid, 90Kg of water, 1.2Kg of formic acid, 0.2Kg of lactic acid, 0.2Kg of citric acid, and 0.5Kg of oxalic acid.

[0041] 2. Preparation method:

[0042] Take 10Kg of pyrolusite in a reaction kettle, add 90Kg of water, stir and heat to 90-95°C, then stop heating, slowly add 22Kg of concentrated sulfuric acid, then continue stirring for 30 minutes, add 0.2Kg of citric acid, 0.2Kg of lactic acid, and 0.5 Kg, react at 90-95°C for 2 hours, finally add 1.2Kg of formic acid, continue to stir and react for 3 hours, filter to obtain manganese sulfate solution. Determination of manganese content in manganese sulfate solution by conventional methods, calculation of manganese leaching rate, while using high performance liquid phase determination of organic content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com