Rectification and regeneration device for heat source tower antifreeze solution

An antifreeze solution and a regeneration device technology, applied in the field of air conditioning and refrigeration, can solve the problems of reduced technical economy, reduced operating pressure, loss of feasibility, etc., and achieve the effects of enhancing technical and economic performance, simplifying regeneration structure, and being conducive to miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

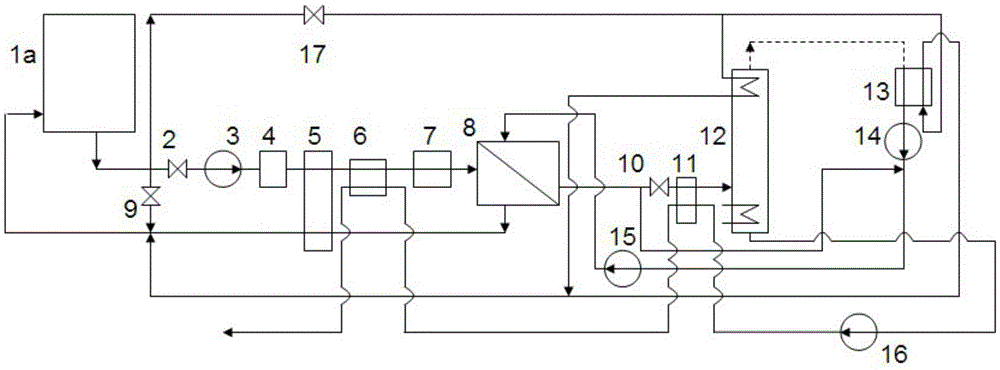

[0024] Embodiment 1. The following descriptions are the specific structural features of the open antifreeze circulation system 1a.

[0025] The working subsystem includes an open antifreeze circulation system 1 a and a circulation loop formed by a second regulating valve 9 .

[0026]The antifreeze circulation system includes a first regulating valve 2, an antifreeze booster pump 3, a filter 4, a first solution heat exchanger 5, a second solution heat exchanger 6, and a heater 7; the open antifreeze circulation system 1a The solution outlet is connected to the antifreeze booster pump 3 through the first regulating valve 2, and the antifreeze booster pump 3 is connected to one end of the low-temperature liquid pipeline of the first solution heat exchanger 5 through the filter 4, and the first solution heat exchanger The other end of the low-temperature liquid pipeline of 5 is connected with one end of the low-temperature liquid pipeline of the second solution heat exchanger 6, a...

Embodiment 2

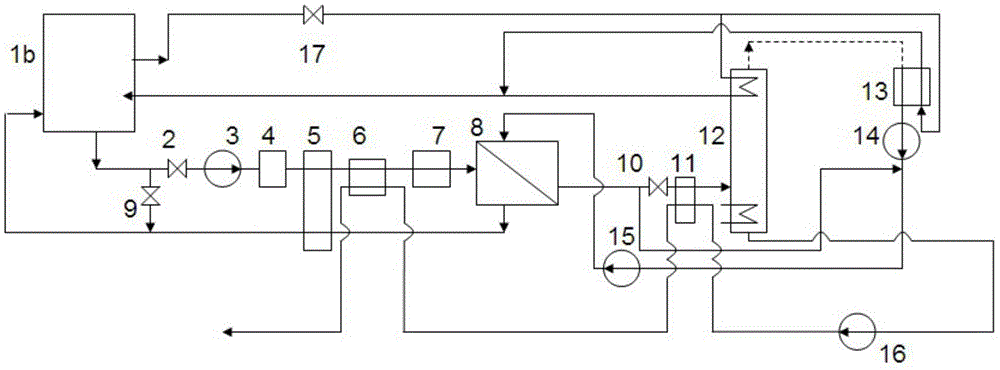

[0058] Embodiment 2. The following are the specific structural features of the closed antifreeze circulation system 1b.

[0059] The working subsystem includes a closed antifreeze circulation system 1b and a circulation loop formed by a second regulating valve 9 .

[0060] The antifreeze circulation system includes a first regulating valve 2, an antifreeze booster pump 3, a filter 4, a first solution heat exchanger 5, a second solution heat exchanger 6, and a heater 7; the closed antifreeze circulation system 1b The solution outlet is connected to the antifreeze booster pump 3 through the first regulating valve 2, and the antifreeze booster pump 3 is connected to one end of the low-temperature liquid pipeline of the first solution heat exchanger 5 through the filter 4, and the first solution heat exchanger The other end of the low-temperature liquid pipeline of 5 is connected with one end of the low-temperature liquid pipeline of the second solution heat exchanger 6, and the o...

Embodiment 1

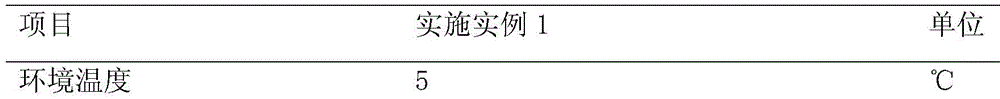

[0091] The calculation parameters of implementation example 1 are shown in Table 1 (for 1kg of water vapor absorbed from the air by the heat source tower heat pump system), the system is in the working regeneration mode, and the design conditions are: ambient temperature 5°C, forward osmosis temperature 5°C, antifreeze solution using Calcium chloride solution, the drawing solution is acetone-water solution, the freezing point of the antifreeze solution is -10°C ~ -12.5°C, the latent heat ratio of the heat source tower is 20%, the dehydration rate is 1.5, and the mass concentration range of the antifreeze solution is 18%. ~20%, the inlet / outlet mass concentration of the drawn solution is 49.4% / 39.4%, and an osmotic pressure difference of 7Mpa can be generated during forward osmosis. The heat exchange temperature difference of the generator is 5°C, and the condensation temperature is -3°C. The calculated total average circulation rate of the antifreeze solution is 633, the avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com