Preparation method of hierarchical-pore CoAlPO-5 molecular sieve

A coalpo-5, multi-level pore technology, applied in the direction of molecular sieve and alkali exchange phosphate, can solve the problems of unfavorable molecular sieve synthesis mechanism, long crystallization time, etc., and achieve the effect of increasing crystallization rate and accelerating chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The present invention is the preparation method of hierarchical porous CoAlPO-5 molecular sieve, and its steps are:

[0012] (1) Mix succinic acid-choline chloride-tetraethylammonium bromide ternary eutectic mixture EM, aluminum isopropoxide and cobalt acetate tetrahydrate evenly, then add appropriate amount of phosphoric acid and hydrofluoric acid to obtain The mixed system is a: Co 2 o 3 ·Al 2 o 3 b:P 2 o 5 c: HF d: EM, where the coefficients are based on molar ratio: a = 0.2~0.6, b = 1.1~2.2, c = 0.45~1.35, d = 62.0~124.0, heated to 120 ℃ to make it evenly mixed, get a mixture;

[0013] (2) Heat the mixture to 175°C, and crystallize for 15 minutes under normal pressure or autogenous pressure;

[0014] (3) Cool the crystallized product to room temperature, repeatedly centrifuge and wash with water and acetone, and dry at 90 °C for 2 hours to obtain a powder product of hierarchically porous CoAlPO-5 molecular sieve.

[0015] According to the preparation method ...

Embodiment 1

[0023] (1) Mix and grind succinic acid, choline chloride, tetraethylammonium bromide, aluminum isopropoxide and cobalt acetate tetrahydrate evenly, transfer to a three-necked flask, and add appropriate amount of phosphoric acid and hydrofluoric acid with a pipette gun , the resulting mixture is a Co 2 o 3 ·Al 2 o 3 · b P 2 o 5 c HF d EM, where the coefficients are based on molar ratio: a = 0.4, b = 1.1, c = 0.45, d = 62.0, heated to a molten state (120 ℃) with an electric heating mantle to make it evenly mixed;

[0024] (2) The above mixture was transferred to a microwave synthesizer, heated to 175 °C under microwave radiation, and crystallized under normal pressure or autogenous pressure for 15 minutes;

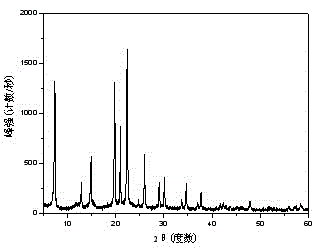

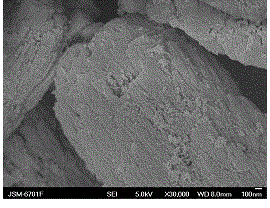

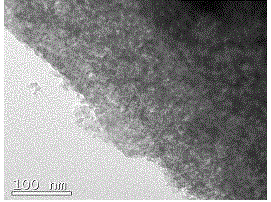

[0025] (3) Cool the obtained crystallized product to room temperature, repeatedly centrifuge and wash it with water and acetone, and dry it in a blast drying oven at 90 °C for 2 hours to obtain a powder product of heteroatom aluminum phosphate molecular sieve CoAlPO-5...

Embodiment 2

[0028] (1) Mix and grind succinic acid, choline chloride, tetraethylammonium bromide, aluminum isopropoxide and cobalt acetate tetrahydrate evenly, transfer to a three-necked flask, and add appropriate amount of phosphoric acid and hydrofluoric acid with a pipette gun , the resulting mixture is a Co 2 o 3 ·Al 2 o 3 · b P 2 o 5 c HF d EM, where the coefficients are based on molar ratio: a = 0.4, b = 1.1, c = 0.90, d = 62.0, heated to a molten state (120 ℃) with an electric heating mantle to make it evenly mixed;

[0029] Steps (2), (3), and (4) are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com