Synthesis technology of active natural product dihydromyricetin

A technology of complexes and acidic conditions, applied in the direction of organic chemistry, can solve problems affecting the extraction and utilization of active ingredients, low resource utilization, and large pollution, and achieve green production procedures, large economic and social benefits, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

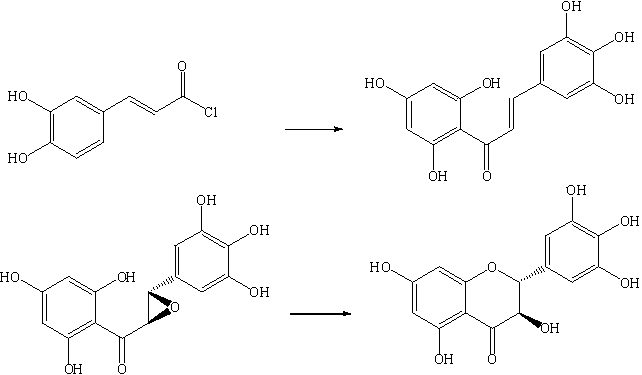

[0016] Example 1 Synthesis of 2-(3,4,5-trihydroxy)-phenylacrylic acid acyl-1,3,5-trihydroxyphenol

[0017] In a 500 L enamel reaction kettle, add 200 L of tetrahydrofuran and 40.0 kg of reaction raw material 3,4,5-trihydroxy-phenylacrylic acid chloride, cool the jacket to about 5°C, and add 12.0 kg of anhydrous aluminum trichloride in batches, And control the temperature at 5-10 ℃, stir the reaction for 2 h to form a complex. Continue to control the temperature within 10 °C, add 25.5 kg of raw material phloroglucinol in batches, and slowly rise to room temperature, then stir for 4 h, and monitor the completeness of the raw material 3,4,5-trihydroxy-phenylacrylic acid chloride by thin layer chromatography. reaction, the acylation reaction was considered complete. Cool down to within 10 °C, slowly add 5% sodium hydroxide solution to about pH 9, and hydrolyze for 0.5 h. Then adjust the pH value to 6-7 with 5% dilute hydrochloric acid, and concentrate to remove tetrahydrofuran. ...

Embodiment 2

[0018] Example 2 Synthesis of 1-(3,4,5-trihydroxy)-phenyl, 2-(2,4,6-trihydroxy)phenyl-oxirane

[0019] In a 500 L enamel reaction kettle, add 53.0 kg of 2-(3,4,5-trihydroxy)-phenylacrylic acid acyl-1,3,5-trihydroxyphenol, stir and dissolve with 300 L of ethanol, and cool the jacket to 5°C About 40.0 kg of m-chloroperoxybenzoic acid was added in batches, and the temperature was controlled at 15 °C. The reaction was stirred for 4 h, and the raw material 2-(3,4,5-trihydroxy)-phenylacrylic acid acyl-1 was monitored by thin-layer chromatography. , 3,5-trihydroxyphenol basically disappeared, and the oxidation reaction was considered complete. Cool down to within 10 °C, slowly add 12.5 L of saturated sodium bisulfite solution to remove peroxy-m-chloroperoxybenzoic acid, concentrate under reduced pressure, and recover methanol. Add 150 L of water and 200 L of dichloromethane to extract twice, combine the organic phases, dry, and concentrate under reduced pressure to obtain 1-(3,4-dih...

Embodiment 3

[0020] The synthesis of embodiment 3 dihydromyricetin

[0021] In a 500 L enamel reaction kettle, add 200 L THF and dry 1-(3,4,5-trihydroxy)-phenyl-2-(2,4,6-trihydroxy)phenyl-epoxy After stirring and dissolving 50.0 kg of ethane intermediate, the temperature of the jacket was lowered to about 5 °C, and the acid catalyst was slowly strengthened with 10.0 L of trifluoroacetic acid, and the temperature was controlled at 0-5 °C, and the reaction was stirred for 5 h. Thin-layer chromatography monitors the complete reaction of the raw material intermediate, which is considered as the completion of the ether-forming reaction. Adjust the pH value to 6-7 with saturated sodium bicarbonate solution, and concentrate to remove tetrahydrofuran. Then extracted twice with 100 L of dichloromethane, combined the organic phases, dried, concentrated under reduced pressure, and dried to obtain 45.8 kg of crude dihydromyricetin. The crude product was dissolved in 230 L of absolute ethanol, finely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com