Snow-melting agent

A snow-melting agent and low-molecular technology, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of unstable dissolution, no snow-melting agent, single mother liquor composition, etc., to prolong the snow-melting time, the snow-melting method is easy, The effect of the simple configuration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] For Shanxi, Hebei and southern regions where the temperature is around -15°C and above, the ratio of various substances:

[0052] Low molecular organic polyol: 30%

[0053] Ethanol: 1%

[0054] Water: 67.4%

[0055] Triethanolamine: 0.8%;

[0056] Metal ion chelates and their salts: 0.1%;

[0057] Sodium metasilicate: 0.2%;

[0058] Benzotriazole: 0.3%;

[0059] Sodium dihydrogen phosphate: 0.2%

[0060] The preparation method is as described above.

Embodiment 2

[0062] For colder regions in the north, such as the three eastern provinces, where the temperature is -25 to -30°C and below, the ratio of various substances:

[0063] Low molecular weight organic polyol: 60%

[0064] Ethanol: 2%

[0065] Water: 34.5%

[0066] Triethanolamine: 1.0%;

[0067] Metal ion chelates and their salts: 0.8%;

[0068] Sodium metasilicate: 0.4%;

[0069] Benzotriazole: 0.8%;

[0070] Sodium dihydrogen phosphate: 0.5%

[0071] The preparation method is as described above.

Embodiment 3

[0072] Embodiment 3: performance measurement

[0073] Metal corrosion test and toxicological indicators

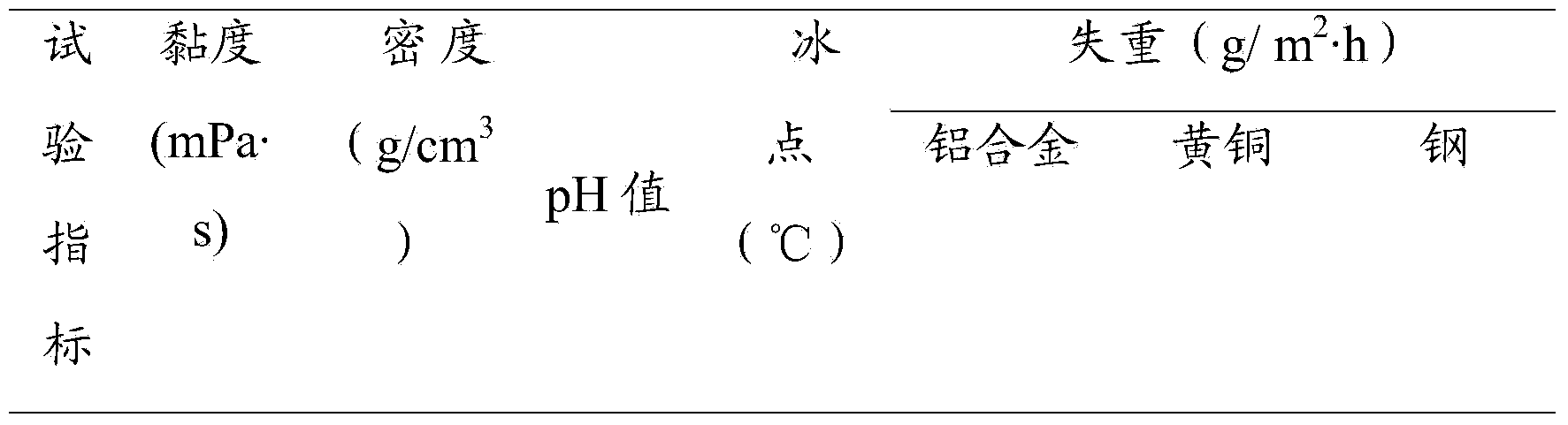

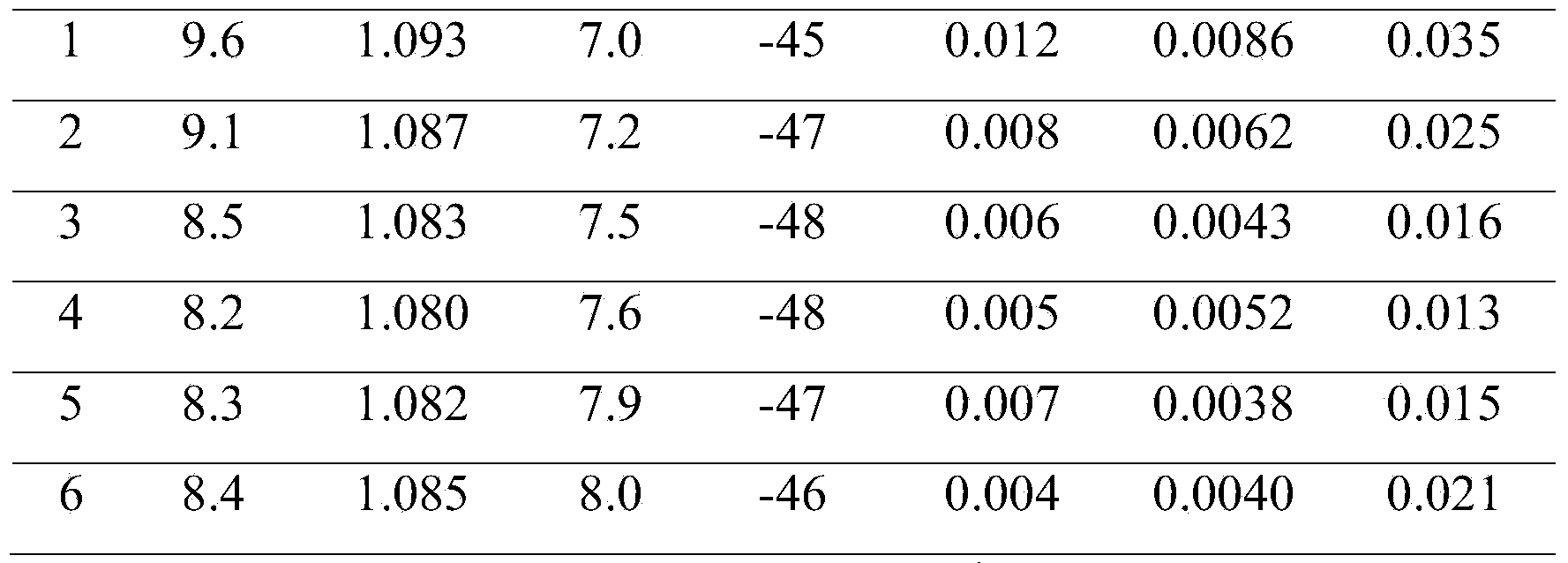

[0074] According to the formula above, different proportions of deicing agent were prepared, and the corrosion test was carried out. Measure performance indicators such as viscosity, specific gravity, pH value, freezing point, etc., then put a certain amount of aluminum alloy, copper, and steel sheet at 25°C, seal and let it stand for 7 days (168h), and measure the effect of different compound formula snow melting agents on metal tests. Corrosion of the sheet, the results are shown in Table 1:

[0075] Table 1 full formula test result

[0076]

[0077]

[0078] The test results of the main technical indicators of the deicing agent are shown in Table 2:

[0079] Test items

Standard Requirements (Liquid)

results of testing

Dissolving speed / (g / min)

≥6.0

11.0

Snow melting and ice melting capacity / (g / min)

≥90% of sodium chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com