Method for producing fresh zanthoxylum oil

A technology of pepper oil and fresh pepper, which is applied in the direction of fat oil/fat production, fat generation, fat oil/fat refining, etc., can solve the problems of complicated process, loss of fresh pepper flavor, precipitation of pepper oil, etc., and achieve simple process and equipment, Avoid waxy and colloidal substances, avoid sedimentation and floc effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

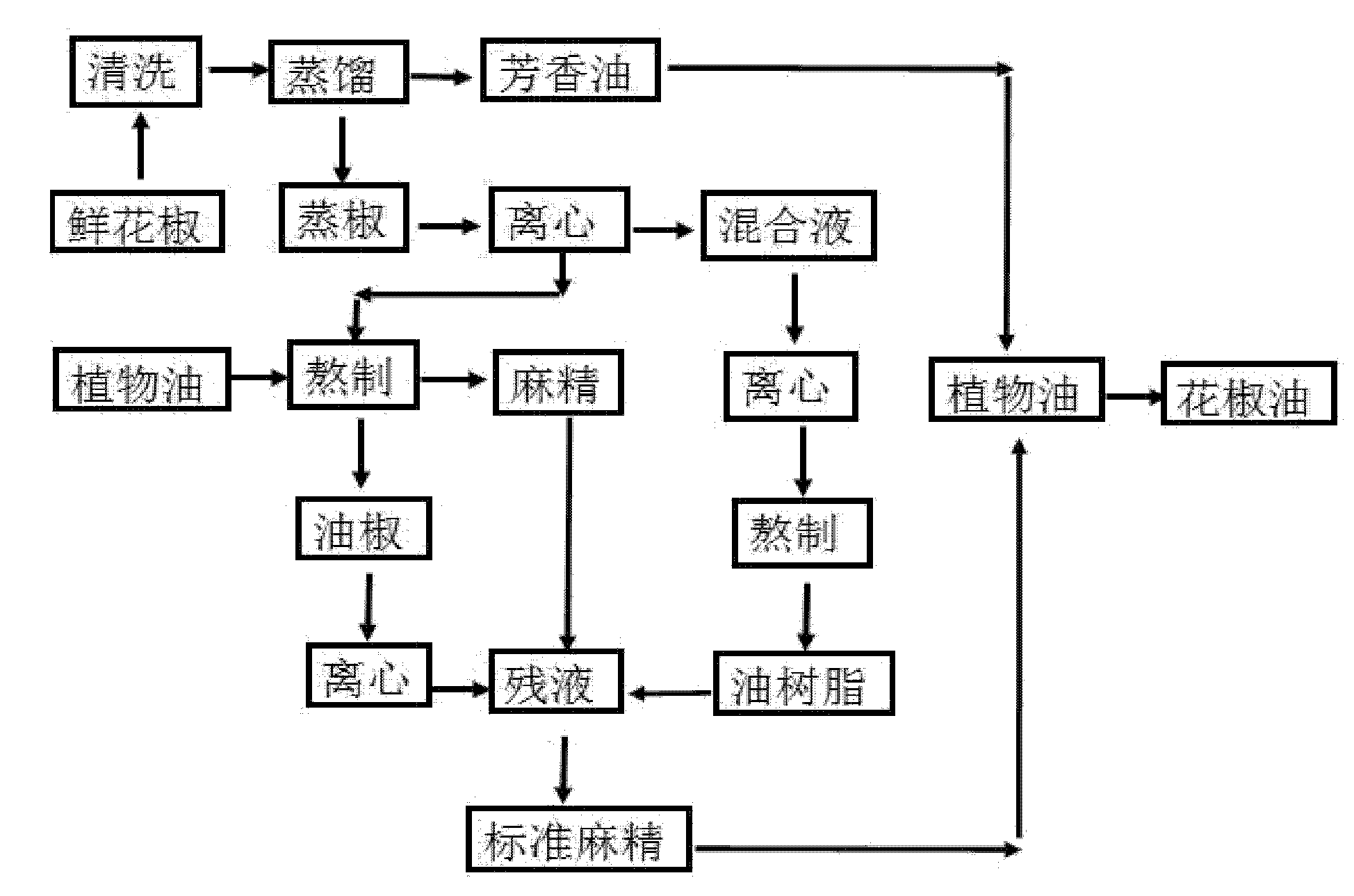

Method used

Image

Examples

preparation example Construction

[0100] (4) Preparation of Zanthoxylum bungeanum oleoresin: remove the water in the mixed system of Zanthoxylum bungeanum oleoresin and water, then heat and boil in the reaction kettle to further remove water;

[0101] (5) Stewing of Zanthoxylum bungeanum essence I: heat and boil the centrifuged Zanthoxylum bungeanum and liquid oil I until the Zanthoxylum bungeanum is golden yellow. Preferably, the weight ratio of Zanthoxylum bungeanum and liquid oil I is 0.5-4:1;

[0102] (6) Collection of Zanthoxylum bungeanum residue: put the boiled Zanthoxylum bungeanum in a filter bag and centrifuge to obtain a centrate;

[0103] (7) Standardization of sesame essence: mix the cooked Zanthoxylum bungeanum I with the centrifuge, add Zanthoxylum bungeanum oleoresin, settle, and filter to obtain Zanthoxylum bungean II;

[0104] (8) Preparation of Zanthoxylum bungeanum oil: mix Zanthoxylum bungeanum II, liquid oil II, and Zanthoxylum aromatic oil to obtain Zanthoxylum bungeanum oil, preferably,...

Embodiment

[0108] raw material

[0109] Green Zanthoxylum bungeanum: Purchased from Zanthoxylum bungeanum base in Qingxi Town, Hanyuan County, Sichuan Province

[0110] Red pepper: purchased from the pepper base of Qingxi Town, Hanyuan County, Sichuan Province

[0111] Rapeseed oil: purchased from Shanghai Kerry Food Industry Co., Ltd.

[0112] Soybean oil: purchased from Shanghai Kerry Food Industry Co., Ltd.

[0113] Corn oil: purchased from Shanghai Kerry Food Industry Co., Ltd.

[0114] Blending oil: purchased from Shanghai Kerry Food Industry Co., Ltd.

[0115] Detection method

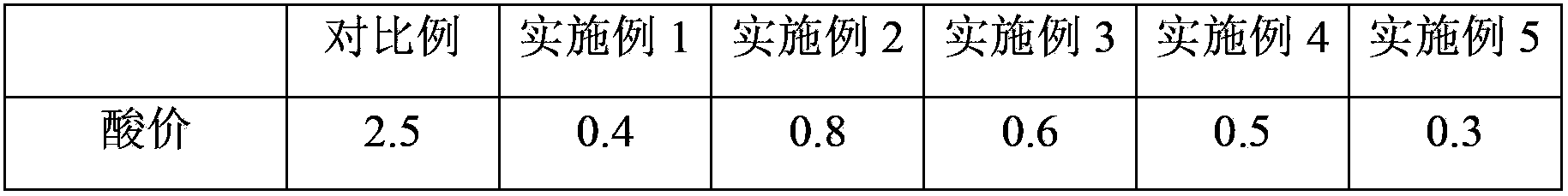

[0116] Acid value: refer to GB / T5530-2005;

[0117] Peroxide value: refer to GB / T5538-2005;

[0118] Amide content: refer to DB51 / T 493-2005

[0119] Moisture content: refer to GB / T 5528-2008

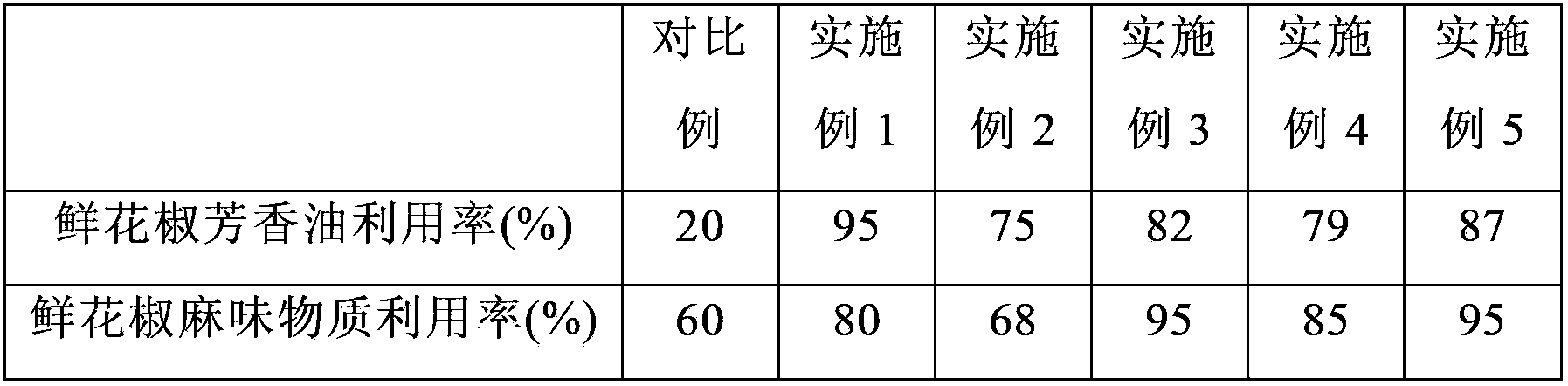

[0120] Utilization rate of fresh pepper aroma oil = (aromatic oil distilled from fresh pepper + aromatic oil in fresh pepper sesame essence) / total aroma oil of fresh pepper * 100%

[0121] Utilization ...

Embodiment 1

[0131] Follow the steps below to produce fresh pepper oil:

[0132] (1) Cleaning: Pick fresh green peppercorns, spread them on the conveyor belt, spray and clean the surface of the peppercorns, and spread them to a thickness of 3cm.

[0133] (2) Extraction of Zanthoxylum bungeanum aromatic oil: Spread the cleaned fresh peppers on a bamboo plaque with a thickness of 5cm, place them in a reaction kettle in layers with a distance of 15cm between layers, and steam distill for 15 minutes at a pressure of 0.08MPa .

[0134] (3) Collection of Zanthoxylum aromatic oil: Collect the distillate through condensing equipment, let it stand for stratification until no more oil comes out, then take out the oil layer and collect it, and then dry it with anhydrous sodium sulfate to obtain a colorless and transparent product with a strong aroma of Zanthoxylum bungeanum Long-lasting prickly ash aroma oil.

[0135] (4) Separation of Zanthoxylum bungeanum liquid: The distilled Zanthoxylum bungean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com