Porous complex composite film oxygen sensor as well as preparation method thereof

An oxygen sensor and composite film technology, applied in the field of porous materials, can solve the problems of poor air and water vapor stability, and achieve the effects of high repeatability, strong anti-interference and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

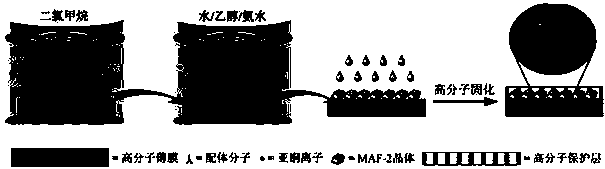

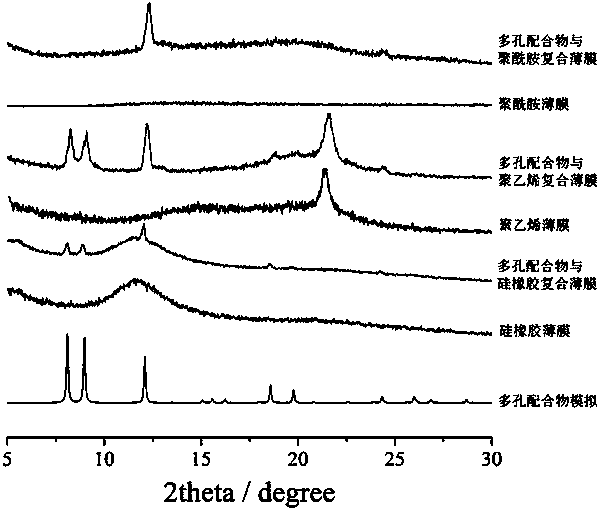

[0037] Example 1 Preparation of MAF-2 and Silicone Rubber Composite Film Oxygen Sensor

[0038] (1) Inject the silicone rubber precursor into the film laminating device made of plexiglass, adjust its thickness to ≈0.2 mm, and place it at room temperature for two days to polymerize and solidify the polymer precursor into a polymer film, and finally cut the film to a suitable size stand-by.

[0039] (2) Then soak the obtained polymer film in dichloromethane solution of 3,5-diethyl-1,2,4-triazole (100 mL, 0.1 mol L -1 ), let stand for 10 minutes until the film completely swells and absorbs the ligand solution, then take out the film and put it into [Cu(NH 3 ) 2 ]OH in ammonia-methanol solution (100 mL, 0.05 mol L -1 , ammonia water / methanol = 1:1), let it stand for another 5 minutes, after the film shrinks and a white crystal film is formed on the surface, carefully take out the film, wash it with methanol, and dry it.

[0040] (3) Finally, use a spray gun to spray the dich...

Embodiment 2

[0042] Example 2 Preparation of MAF-2 and polyethylene composite film oxygen sensor

[0043] (1) Cut a commercial polyethylene film with a thickness of ≈0.2 mm to a suitable size.

[0044] (2) Then soak the obtained polymer film in acetone solution of 3,5-diethyl-1,2,4-triazole (100 mL, 0.05 mol L -1 ), let stand for 9 minutes until the film completely swells and absorbs the ligand solution, then take out the film and put it into [Cu(NH 3 ) 2 ] 2 CO 3 Ammonia-methanol solution (100 mL, 0.02 mol L -1 , ammonia water / methanol=2:1), let it stand for another 4 minutes, after the film shrinks and a white crystal film is formed on the surface, carefully take out the film, wash it with methanol, and dry it.

[0045] (3) Finally, use a spray gun to spray the benzene solution (90°C, 2mL, 5% wt.) of the polyethylene precursor on the surface of the crystal film, and let it stand for a period of time to form a layer of protection on the surface of the crystal film after the polymer...

Embodiment 3

[0046] Example 3 Preparation of MAF-2 and Polyamide Composite Film Oxygen Sensor

[0047] (1) Cut a commercial polyamide film with a thickness of ≈0.2 mm to a suitable size.

[0048] (2) Then soak the obtained polymer film in acetone solution of 3,5-diethyl-1,2,4-triazole (100 mL, 0.2 mol L -1 ), let it stand for 12 minutes until the film is completely swollen and absorbs the ligand solution, then take out the film and put it into [Cu(NH 3 ) 2 ]NO 3 Ammonia-methanol solution (100 mL, 0.2 mol L -1 , ammonia water / methanol=1:2), let stand for another 6 minutes, after the film shrinks and a white crystal film is formed on the surface, carefully take out the film, wash it with methanol, and dry it.

[0049] (3) Finally, use a spray gun to spray the dichloromethane solution (2mL, 20% wt.) of the silicone rubber precursor on the surface of the formed crystal film, and let it stand for a period of time to form a protective layer on the surface of the crystal film after the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com