Fixed supporting beam vibration electromagnetic self-powered microsensor in radio frequency receiving and transmitting assembly of Internet of Things

A radio frequency transceiver and micro-sensor technology, applied in piezoelectric devices/electrostrictive devices, electromagnetic wave systems, generators/motors, etc., can solve problems such as impermissibility, limited energy supply life, large size and weight, etc., and achieve suppression Effects of dithering, improved electromagnetic compatibility, size and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

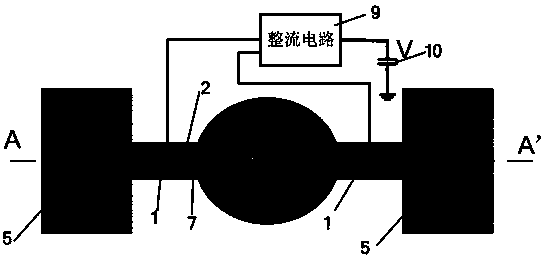

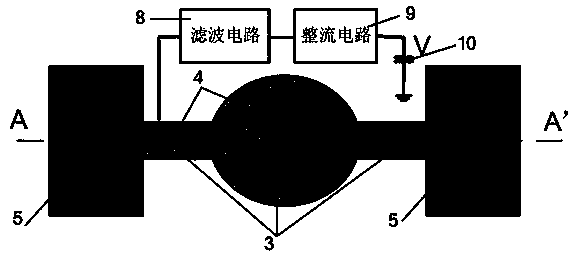

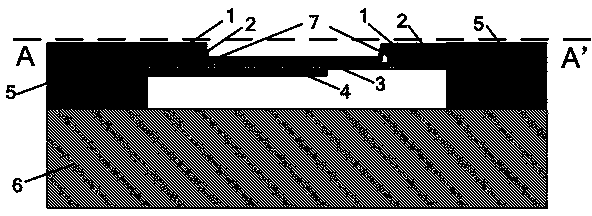

[0015] The specific implementation scheme of the fixed-support beam vibration / electromagnetic self-powered microsensor in the radio frequency transceiver component of the Internet of Things of the present invention is as follows:

[0016] On the gallium arsenide substrate 6 is provided: a MEMS fixed support beam, and a filtering circuit 8 , a rectification circuit 9 and an energy storage capacitor 10 are supplemented on the periphery of the fixed support beam.

[0017] The MEMS fixed support beam consists of five layers, from top to bottom: upper electrode 1, piezoelectric film 2, lower electrode 7, silicon nitride dielectric layer 3 and rectangular microstrip patch antenna 4. The fixed support beam structure is wide in the middle and narrow in both sides. The fixed beam is used to integrate two kinds of energy harvesting modules, the piezoelectric transducer and the rectenna system. The material used for the upper electrode 1 and the lower electrode 7 is Au.

[0018] The pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com