Preparation method of stirring type coarse rice fermented drink

A stirring type, brown rice technology, applied in the direction of food preparation, bacteria used in food preparation, function of food ingredients, etc., can solve the problems of reducing fat content, flatulence, discomfort, not easy to absorb, etc., to increase the content and facilitate digestion Effects of absorption and weight control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Cultivation of composite strains

[0028] Prepare potato medium: peel and cut potatoes into pieces, weigh 20g of potato pieces, add 100mL of pure water, boil for 30min, filter with 120 mesh filter cloth, add 2g of glucose to the filtrate, stir evenly, add pure water to make up to 100mL, sterilized at 121°C for 15min;

[0029] Inoculate 0.08g of Lactobacillus plantarum, 0.04g of Lactobacillus acidophilus, 0.04g of Lactobacillus rhamnosus and 0.04g of Lactobacillus casei into 100mL potato culture medium, and cultivate it at 40±2°C for 7h. Obtain the culture solution of compound strains, cool to room temperature and store at 4°C;

[0030] 2. Ingredients

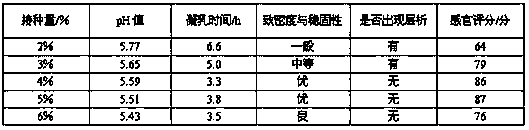

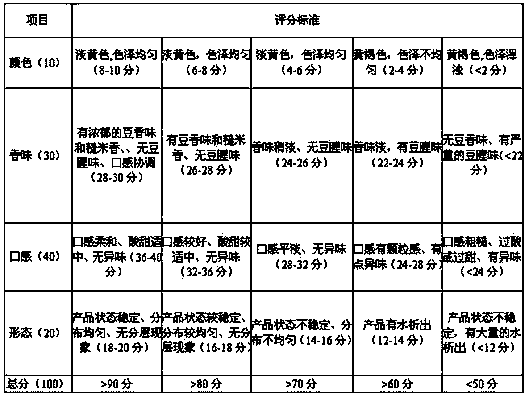

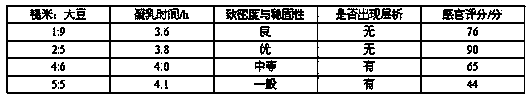

[0031] 2.1. According to the number of parts by weight, weigh 60g of puffed brown rice flour, add 480mL of pure water and stir into a uniform paste to obtain brown rice paste; heat the brown rice paste to 60°C in a water bath at 73°C, and add a concentration of 5wt% citric acid solution to adjust the pH value of bro...

Embodiment 2

[0036] 1. Cultivation of composite strains

[0037]Prepare potato medium: peel and cut potatoes into pieces, weigh 20g of potato pieces, add 100mL of pure water, boil for 30min, filter with 120 mesh filter cloth, add 2g of glucose to the filtrate, stir evenly, add pure water to make up to 100mL, sterilized at 121°C for 15min;

[0038] Inoculate 0.05g of Lactobacillus plantarum, 0.03g of Lactobacillus acidophilus, 0.03g of Lactobacillus rhamnosus and 0.03g of Lactobacillus casei into 70mL potato culture medium, and culture it at 40±2°C for 7h to obtain Composite strain culture solution, cooled to room temperature and stored at 4°C;

[0039] 2. Ingredients

[0040] 2.1. In terms of parts by weight, weigh 65g of puffed brown rice flour, add 650mL of pure water and stir into a uniform paste to obtain brown rice paste; heat the brown rice paste to 65°C in a water bath at 77°C, and add a concentration of 10wt% citric acid solution to adjust the pH value of brown rice paste to 6.8...

Embodiment 3

[0045] 1. Cultivation of composite strains

[0046] Prepare potato medium: peel and cut potatoes into pieces, weigh 20g of potato pieces, add 100mL of pure water, boil for 30min, filter with 120 mesh filter cloth, add 2g of glucose to the filtrate, stir evenly, add pure water to make up to 100mL, sterilized at 121°C for 15min;

[0047] Inoculate 0.05g of Lactobacillus plantarum, 0.0275g of Lactobacillus acidophilus, 0.0275g of Lactobacillus rhamnosus and 0.0275g of Lactobacillus casei into 66.25mL of potato culture medium, and incubate at 40±2°C for 7 hours. Obtain the culture solution of compound strains, cool to room temperature and store at 4°C;

[0048] 2. Ingredients

[0049] 2.1. In terms of parts by weight, weigh 62g of puffed brown rice flour, add 560mL of pure water and stir into a uniform paste to obtain brown rice paste; heat the brown rice paste to 62°C in a water bath at 75°C, and add a concentration of 8wt% citric acid solution to adjust the pH value of the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com