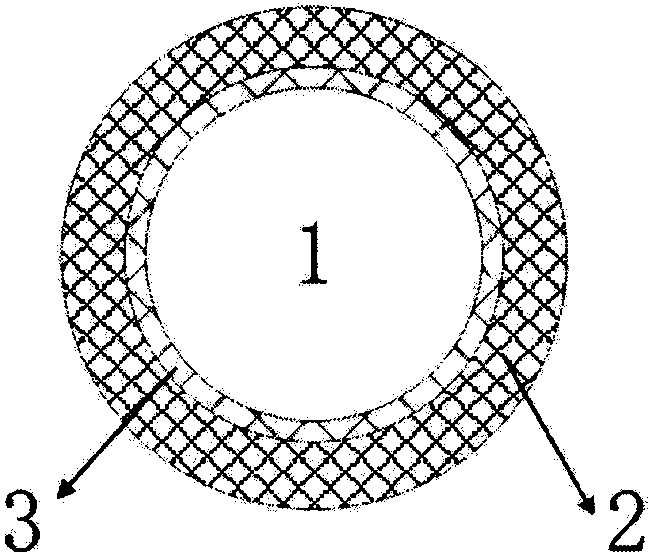

Keratoprosthesis and manufacturing method thereof

A technology of artificial cornea and cornea, applied in the field of biomedical engineering, can solve the problems of poor suturability and achieve the effects of preventing separation, avoiding spontaneous dislocation, and simplifying implantation surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take 1g of dry fluffy silk fibroin and put it into a glass bottle, add 4g of formic acid dropwise, fully stir to dissolve, then add 5g of sodium chloride (particle size 50-100μm), and mix well with the silk fibroin solution to make a slurry; take an appropriate amount Put the mixture into a special mold for artificial corneal stent and mold it. Put the stent together with the mold into a beaker filled with absolute ethanol for soaking. After 5 minutes, replace it with another beaker filled with absolute ethanol. Continue soaking for 5 minutes before taking it out. ;The bracket blank is placed on a certain curved surface device, and a hole with a diameter of 4mm is drilled at the central beam position with the prepared ring knife.

[0047] Put the punched stent blank on the convex mold to dry, and drop the deoxygenated HEMA thermal polymerization solution on the surface, HEMA:BIS:AIBN=1:0.03:0.002, until the stent is completely wetted (the surface has no obviously liquid...

Embodiment 2

[0051] Take 1g of dry fluffy silk fibroin and put it into a glass bottle, add 6g of formic acid dropwise, fully stir to dissolve, then add 10g of potassium chloride (particle size 40-80μm), and mix well with the silk fibroin solution to make a slurry; take an appropriate amount Put the mixture into a special mold for artificial corneal stent and mold it. Put the stent together with the mold into a beaker filled with absolute ethanol for soaking. After 5 minutes, replace it with another beaker filled with absolute ethanol. Continue soaking for 5 minutes before taking it out. . The stent blank is placed on a certain curved surface device, and a hole with a diameter of 4mm is punched at the central beam position with the prepared ring knife.

[0052] The punched stent blank was placed on the convex mold to dry, and the deoxygenated HEMA thermal polymerization solution (HEMA:BIS:AIBN=1:0.03:0.002) was added dropwise to the surface until the stent was completely wetted (the surface...

Embodiment 3

[0056] Take 1g of dry fluffy silk fibroin and put it into a glass bottle, add 8g of formic acid dropwise, stir and dissolve it fully, then add 15g of sodium carbonate (particle size 30-80μm), and mix well with the silk fibroin solution to make a slurry; take an appropriate amount of the mixture Place it in a special mold for artificial corneal stents and mold it. Put the stent together with the mold into a beaker filled with absolute ethanol for soaking. After 5 minutes, replace it with another beaker filled with absolute ethanol. Continue soaking for 5 minutes before taking it out; The stent blank is placed on a certain curved surface device, and a hole with a diameter of 4mm is punched at the central beam position with a ring knife prepared in advance).

[0057] The punched stent blank was placed on the convex mold to dry, and the deoxygenated HEMA thermal polymerization solution (HEMA:BIS:AIBN=1:0.03:0.002) was added dropwise to the surface until the stent was completely wet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com