A kind of method for preparing polyphosphoric acid

A technology of polyphosphoric acid and dilute phosphoric acid, which is applied in the field of phosphorus chemical industry, can solve the problems of high production energy consumption, easy fluctuation of pressure, small mass transfer and heat transfer, etc., so as to improve the utilization rate of heat energy, avoid production accidents, and improve heat transfer. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

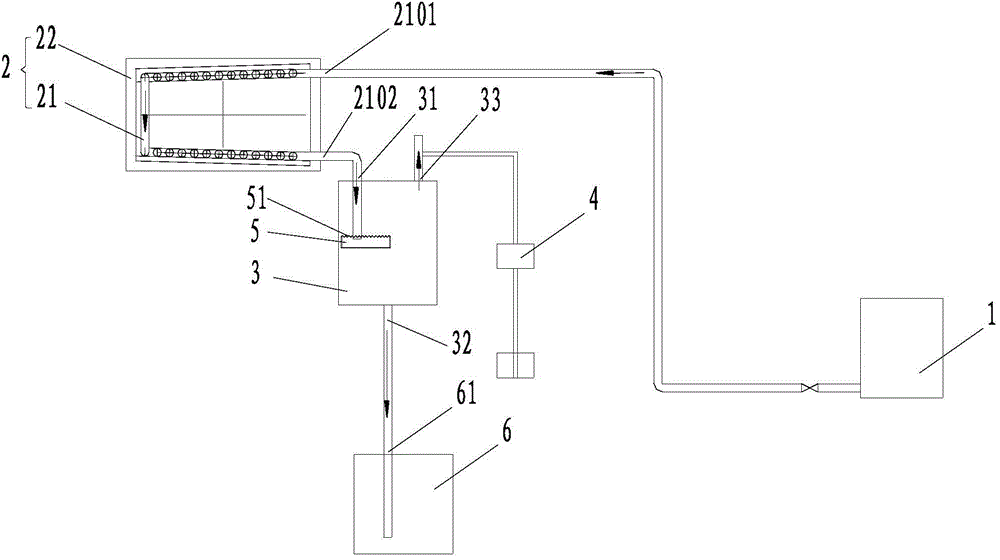

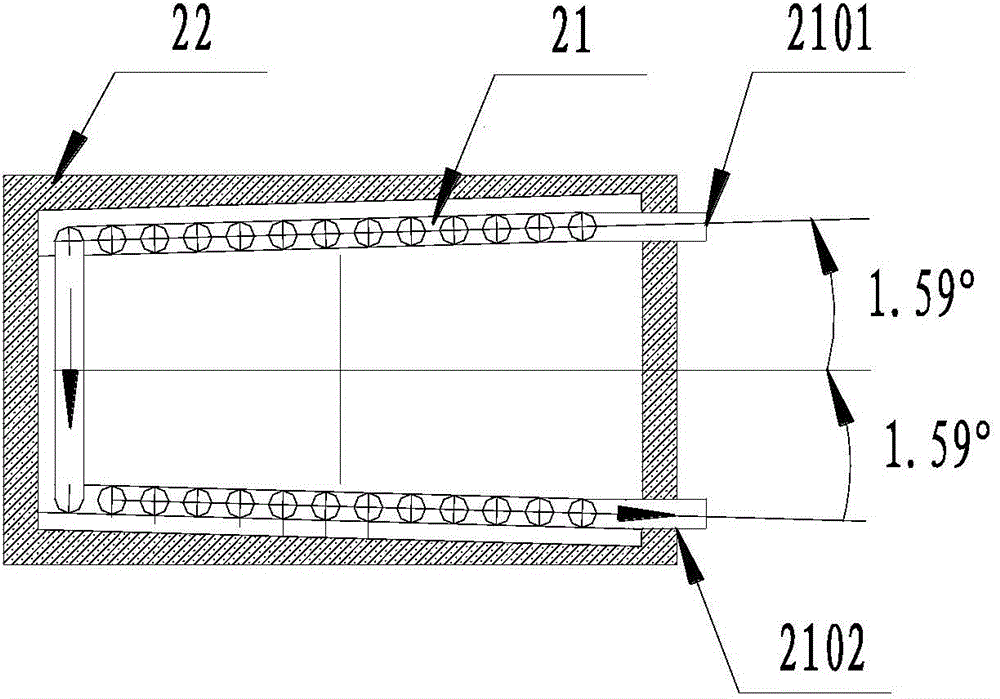

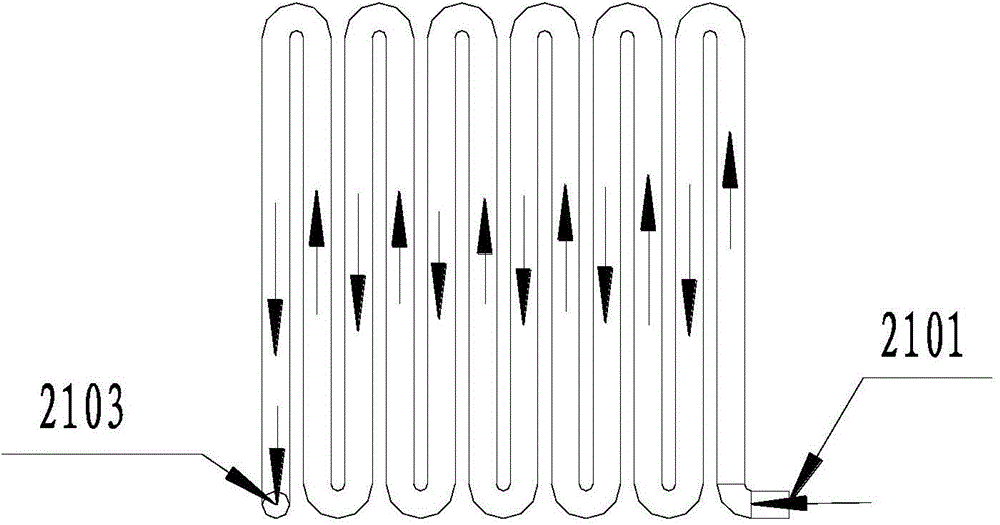

[0041] Such as figure 1 As shown, the device for implementing the method for preparing polyphosphoric acid in this embodiment includes a heater 2, a separator 3, and a concentrated acid tank 6, and the inside of the separator 3 is in communication with a vacuum barostat 4; figure 2 As shown, the heater 2 includes a heat exchange tube 21 and a heat ventilation zone. The heat exchange tube 21 is a graphite tube. The outer wall of the graphite tube is provided with an anti-oxidation coating which does not react with high-temperature flue gas; The ventilation area is surrounded by an insulation layer 22, and the heat exchange pipe 21 is located in the heat ventilation area; the heat exchange pipe 21 is coiled in an S shape in the heat ventilation area. image 3 Is a top view of the upper part of the heat exchange tube 21, Figure 4 It is a bottom view of the lower part of the heat exchange tube 21, the upper outlet 2103 of the heat exchange tube is connected with the lower inlet 2104...

Embodiment 2

[0046] The method for preparing polyphosphoric acid by using the device for preparing polyphosphoric acid in Example 1, wherein the heat exchange tube 21 is inclined downward at an angle of 1° from the acid inlet 2101 of the heat exchange tube to the acid outlet 2102 of the heat exchange tube:

[0047] The dilute phosphoric acid with a mass concentration of 45% from the dilute acid tank 1 enters the heat exchange tube 21 through the acid inlet 2101 of the heat exchange tube. The pressure at the acid inlet 2101 of the heat exchange tube is -594mmHg, and the dilute phosphoric acid passes through the hot ventilation zone. , That is, inside the insulation layer 22, heat exchange with the yellow phosphorous waste gas (220°C) in the shell of the heat exchange tube 21 to heat up to 210°C. At this time, the insulation layer 22 is under normal pressure, and at the same time, phosphoric acid polymerizes to form Polyphosphoric acid, the acid liquid exits the heat exchanger 2 from the acid ou...

Embodiment 3

[0050] Using the method for preparing polyphosphoric acid using the device for preparing polyphosphoric acid in Example 1, the heat exchange tube 21 is inclined downward at an angle of 3° from the acid inlet 2101 of the heat exchange tube to the acid outlet 2102 of the heat exchange tube:

[0051] The dilute phosphoric acid with a mass concentration of 70% from the dilute acid tank 1 enters the heat exchange tube 21 through the acid inlet 2101 of the heat exchange tube. The pressure at the acid inlet 2101 of the heat exchange tube is -450mmHg, and the dilute phosphoric acid passes through the hot ventilation zone. , That is, inside the insulation layer 22, heat exchange with the yellow phosphorus tail gas (200°C) in the shell of the heat exchange tube 21 to increase the temperature to 195°C. At this time, the insulation layer 22 is at normal pressure, and under high temperature conditions, phosphoric acid polymerizes Polyphosphoric acid, the acid liquid exits the heat exchanger 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com