Preparation method of 17hydroxy-pregnane-4-alkene-3,20-diketone-21-acetic ester

A technology of acetate and pregnan, which is applied in the field of preparation of 17-hydroxy-pregn-4-ene-3,20-dione-21-acetate, can solve the problems of low yield and high cost, and achieves a high yield High, stable yield and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

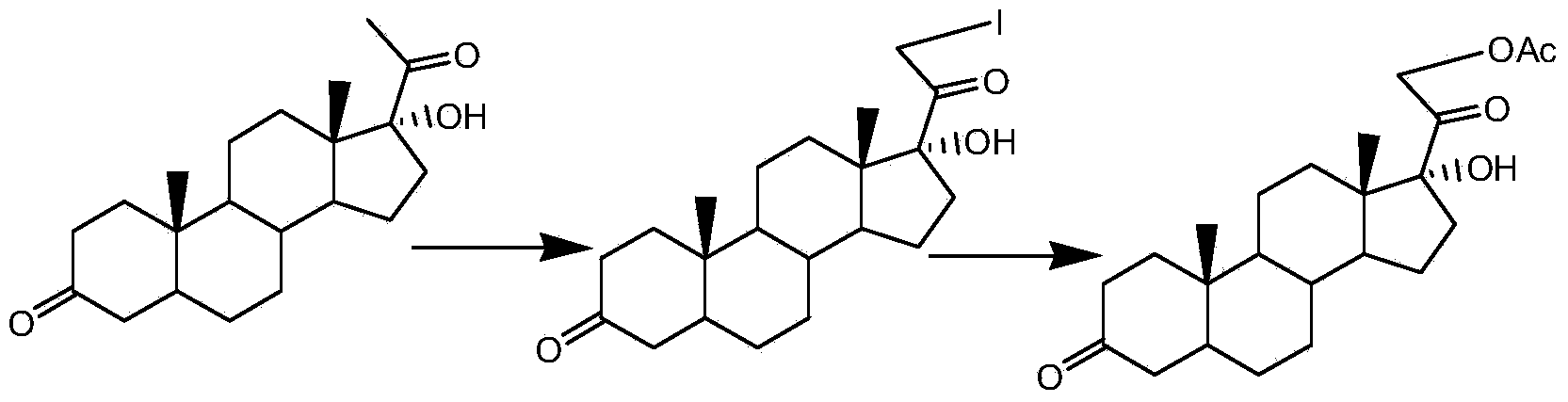

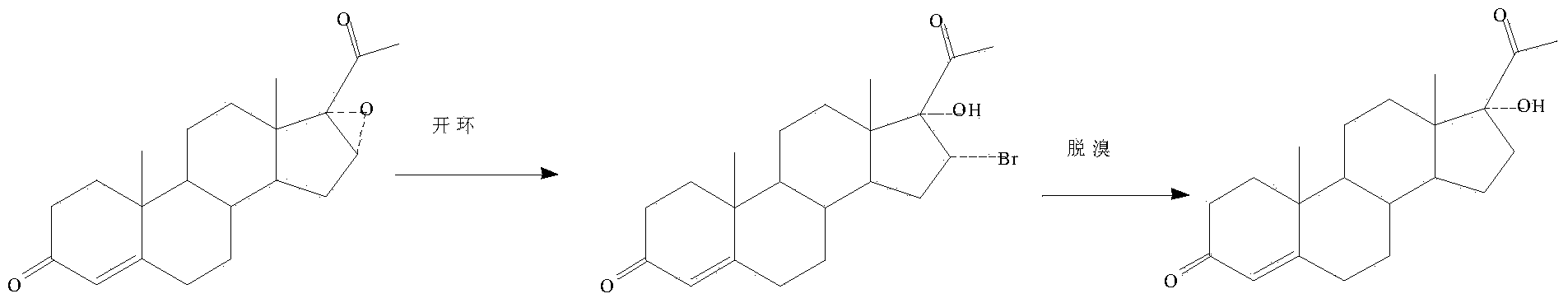

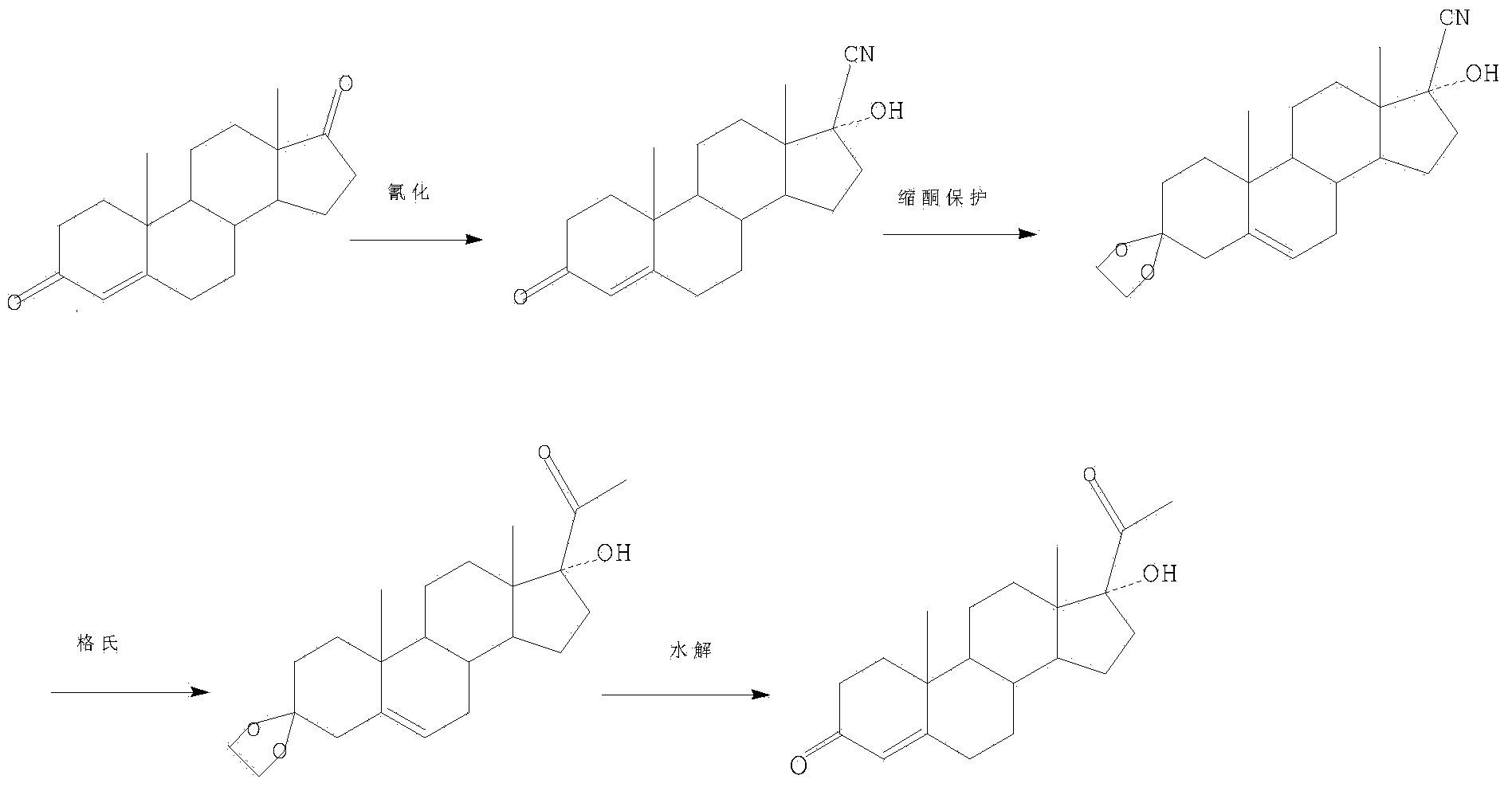

[0033] The reaction scheme of the present invention is as follows:

[0034]

[0035] Cyanation reaction

[0036] Put 100 milliliters of methanol, 50 grams of acetone cyanohydrin, and 100 grams of the compound represented by formula (II) into a three-necked flask. Turn on the stirring and slowly raise the temperature to 35°C. The prepared potassium carbonate solution was slowly added dropwise, and the temperature was controlled at 32° C. for 20 h. TLC detection confirmed that the raw material point is very small and the raw material point is no longer reduced, then cooled to 5°C, slowly passed the material into a beaker of 2 liters of water that had been cooled to below 10°C in advance, and stood still for more than 2h. Filter and wash with water until neutral. Add the filter cake to the prepared dilute hydrochloric acid, stir for 2 hours, filter, wash the filter cake with a large amount of water until PH = 6.0-6.5, filter, and discharge. The filter cake was transferred ...

Embodiment 2

[0044] Cyanation reaction

[0045] Put 100 milliliters of ethanol, 100 grams of sodium cyanide, and 100 grams of the compound represented by formula (II) into a three-necked flask. Turn on the stirring and slowly raise the temperature to 38°C. The prepared sodium hydroxide solution was slowly added dropwise, and the temperature was controlled at 38° C. for 20 h. TLC detection confirmed that the raw material point is very small and the raw material point is no longer reduced, then cooled to 0 °C, slowly passed the material into a beaker of 2 liters of water that had been cooled to below 10 °C in advance, and stood still for more than 2 hours. Filter and wash with water until neutral. Add the filter cake to the prepared dilute hydrochloric acid, stir for 2 hours, filter, wash the filter cake with a large amount of water until PH = 6.5, filter, and discharge. The filter cake was transferred to an oven and dried at 72°C for 12h. In crude cyanide. The yield is about 97%, HPLC≥...

Embodiment 3

[0053] Cyanation reaction

[0054] Put 100 milliliters of acetone, 70 grams of potassium cyanide, and 100 grams of the compound represented by formula (II) into a three-necked flask. Turn on the stirring and slowly raise the temperature to 50°C. The prepared sodium carbonate solution was slowly added dropwise, and the temperature was controlled at 50°C for 18 hours. TLC detection confirmed that the raw material point is very small and the raw material point is no longer reduced, then cooled to 0 °C, slowly passed the material into a beaker of 2 liters of water that had been cooled to below 10 °C in advance, and stood still for more than 2 hours. Filter and wash with water until neutral. Add the filter cake to the prepared dilute hydrochloric acid, stir for 2 hours, filter, wash the filter cake with a large amount of water until PH = 6.5, filter, and discharge. The filter cake was transferred to an oven and dried at 70°C for 12h. In crude cyanide. The yield is about 96%, H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com