A kind of preparation method of special slump retaining agent for cross-linked polycarboxylic acid and slump retainer prepared by the method

A technology of slump-retaining agent and polycarboxylic acid, which is applied in the field of chemical building materials and construction, can solve the problems of double bond oxidation damage, polymerization activity influence, difficult-to-polymerize products, etc., so that it is not easy to self-polymerize, good for retention, and easy for esterification reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

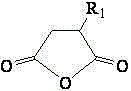

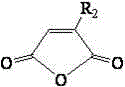

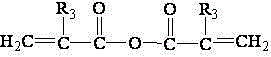

[0044]Step 1, preparation of bifunctional macromonomers: 150.00 g of 3-methyl-3-butenyl polyethylene glycol (TPEG) with a molecular weight of 2400 and 30.35 g of maleic anhydride were added to the reactor, under nitrogen protection. The temperature was raised to 60 °C, 1.06 g of concentrated sulfuric acid, and 1.00 g of p-toluenesulfonic acid were added, and the temperature was continued to slowly rise to 80 °C, kept at a constant temperature for 2 h, and cooled to 70 °C to obtain bifunctional macromonomers, unsaturated polyethers and unsaturated polyethers. Mixture A of saturated acid anhydride, total 182.41 g.

[0045] Step 2, copolymerization reaction: add 8.69 g of itaconic acid and 1.16 g of ammonium persulfate to the reactor containing 182.41 g of mixture A, react at 70° C. for 1.5 h, then add 60.00 g of water and stir evenly, and then add alkene dropwise. A mixed aqueous solution of sodium propyl sulfonate and isopropyl alcohol (including 11.08 g of sodium allyl sulfona...

Embodiment 2

[0048] Step 1, preparation of bifunctional macromonomer: 150.00g of 2-methylallyl polyethylene glycol (HPEG) with a molecular weight of 2400 and 27.04g of itaconic anhydride were added to the reactor, and under nitrogen protection, the temperature was increased. To 55°C, add 2.38g of concentrated sulfuric acid, continue to slowly heat up to 70°C, keep the temperature for 2 hours, and cool down to 60°C to obtain a mixture A containing bifunctional macromonomer, unsaturated polyether and unsaturated acid anhydride, with a total amount of 179.42g .

[0049] Step 2, copolymerization reaction: add 4.87 g of acrylic acid, 3.00 g of methacrylic acid, and 1.75 g of potassium persulfate to the reactor containing 179.42 g of mixture A, react at 60° C. for 1 h, then add 20.00 g of water, stir evenly, and then separate A mixed aqueous solution of sodium methacrylic acid sulfonate and mercaptopropionic acid (including 7.69 g of sodium methacrylic acid sulfonate, 0.72 g of mercaptopropionic...

Embodiment 3

[0052] Step 1, preparation of bifunctional macromonomer: 150.00 g of allyl polyethylene glycol (APEG) with a molecular weight of 1200 and 41.62 g of maleic anhydride were added to the reactor, and under nitrogen protection, the temperature was raised to 60 °C, 2.69 g of p-toluenesulfonic acid was added, the temperature was continued to slowly rise to 110 °C, the temperature was kept constant for 2.5 h, and the temperature was lowered to 70 °C to obtain a mixture A containing bifunctional macromonomer, unsaturated polyether and unsaturated acid anhydride, with a total amount of 194.31 g.

[0053] Step 2, copolymerization reaction: add 12.66 g of methacrylic acid and 1.31 g of ammonium persulfate to the reactor containing 194.31 g of mixture A, react at 50 °C for 0.5 h, then add 1.00 g of potassium persulfate, and react at 70 °C 0.5h, then add 70.00g of water and stir evenly, and then dropwise add the mixed aqueous solution of sodium styrene sulfonate and thioglycolic acid (among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com