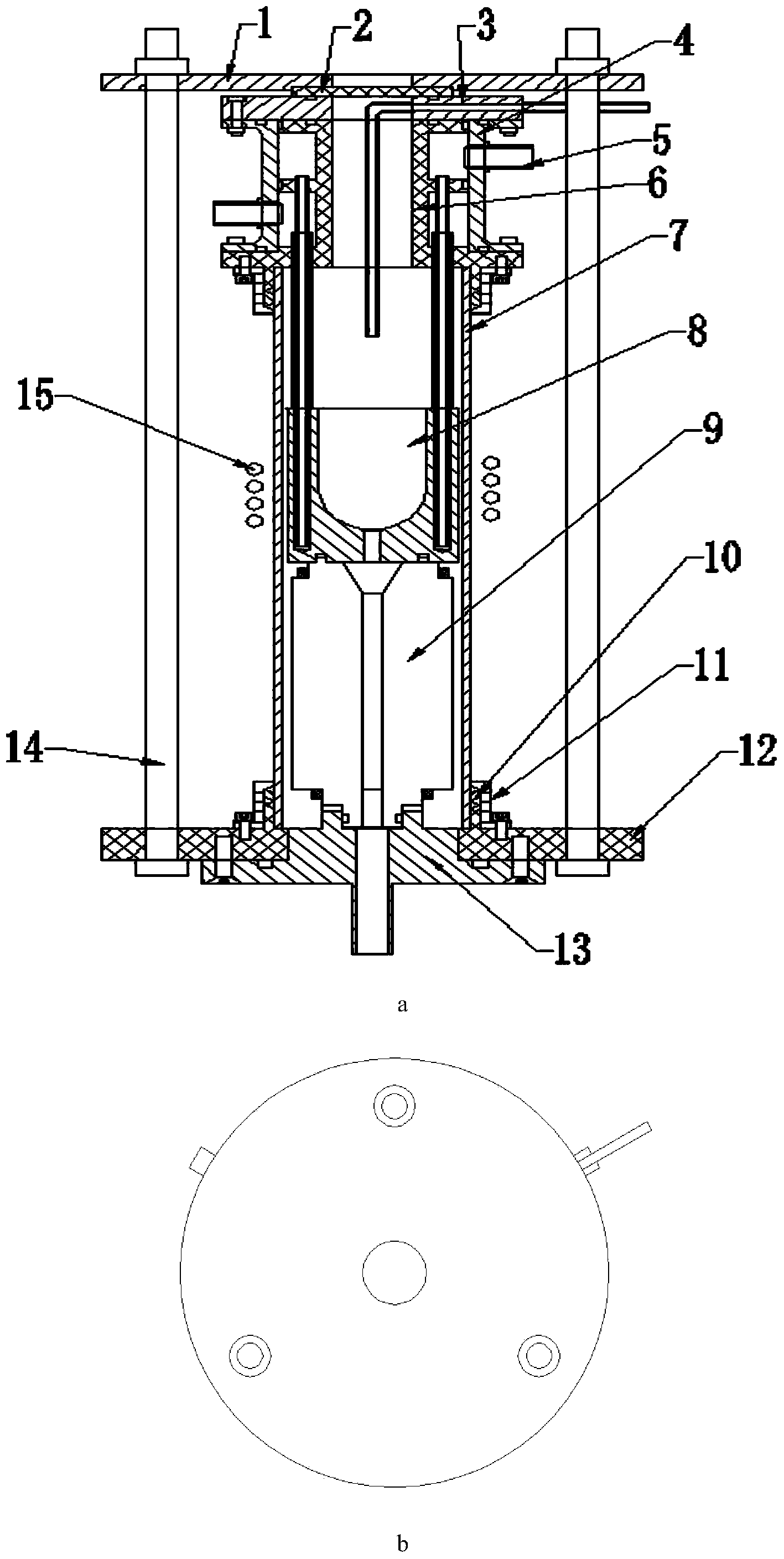

Smelting and casting method and casting device of titanium-based amorphous composite material

An amorphous composite material, titanium-based technology, applied in the configuration of casting equipment, manufacturing tools, indicating equipment/measuring equipment, etc., can solve problems such as difficult temperature measurement, segregation of high melting point material components, and affecting casting performance, etc., to achieve simplification process, avoid pollution, and achieve the effect of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

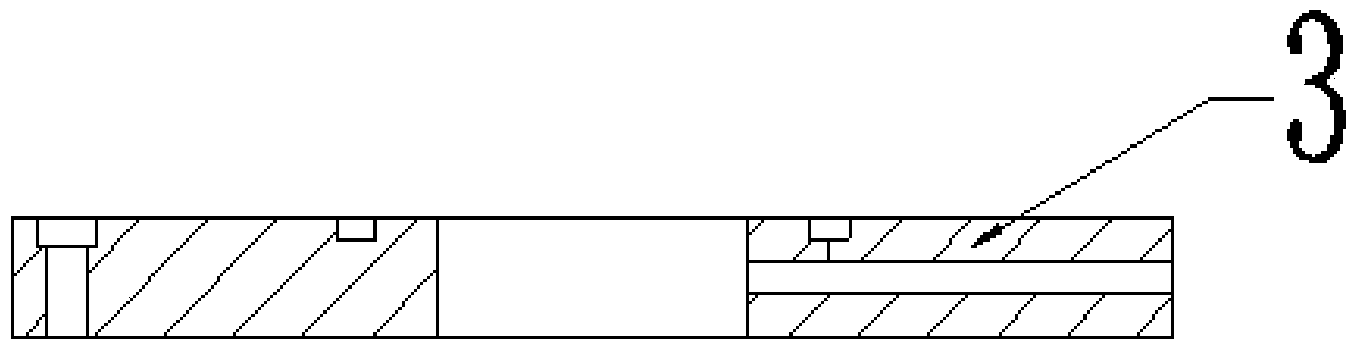

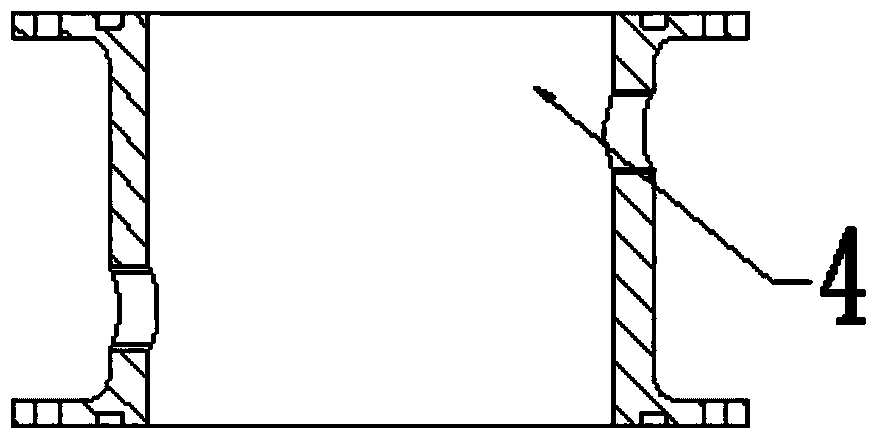

Method used

Image

Examples

Embodiment 1

[0057] This embodiment is a preparation method of a titanium-based amorphous composite material, and the composition of the amorphous composite material is Ti 46 Zr 20 Nb 12 Cu 5 be 15 , A rod with a diameter of Φ12mm and a length of 140mm made by suction casting in a water-cooled copper crucible. The concrete process of this embodiment is:

[0058] Step 1, smelting the alloy master ingot: Melting Ti, Zr, Nb, Cu, Be with a purity greater than 99.9% in two steps through an electric arc melting furnace under the protection of argon. The electric arc melting furnace can simultaneously melt three alloy ingots; each alloy ingot has a weight of 30 g.

[0059] The specific process of smelting alloy master ingot is:

[0060] The first step is to melt the TiZrNb alloy ingot. First, Ti, Zr, and Nb with high melting points are smelted into TiZrNb melt; the power of the arc melting furnace is turned off, and the TiZrNb melt is cooled and solidified to form a TiZrNb alloy ingot. Tu...

Embodiment 2

[0080] This embodiment is a preparation method of a titanium-based amorphous composite material, and the composition of the amorphous composite material is Ti 48 Zr 20 Nb 12 Cu 5 be 15 , A rod with a diameter of Φ12mm and a length of 140mm made by suction casting in a water-cooled copper crucible. The concrete process of this embodiment is:

[0081] Step 1, smelting the alloy master ingot: Melting Ti, Zr, Nb, Cu, Be with a purity greater than 99.9% in two steps through an electric arc melting furnace under the protection of argon. The electric arc melting furnace can simultaneously melt three alloy ingots; each alloy ingot has a weight of 30g.

[0082] The specific process of smelting alloy master ingot is:

[0083] The first step is to melt the TiZrNb alloy ingot. First, Ti, Zr, and Nb with high melting points are smelted into TiZrNb melt; the power of the arc melting furnace is turned off, and the TiZrNb melt is cooled and solidified to form a TiZrNb alloy ingot. Tur...

Embodiment 3

[0103] This embodiment is a preparation method of a titanium-based amorphous composite material, and the composition of the amorphous composite material is Ti 48 Zr 20 Nb 12 Cu 5 be 15 , a rod with a diameter of Φ12mm and a length of 30mm made by suction casting in a water-cooled copper crucible. The concrete process of this embodiment is:

[0104] Step 1, smelting the alloy master ingot: Melting Ti, Zr, Nb, Cu, Be with a purity greater than 99.9% in two steps through an electric arc melting furnace under the protection of argon. The electric arc melting furnace can simultaneously melt three alloy ingots; each alloy ingot has a weight of 30 g.

[0105] The specific process of smelting alloy master ingot is:

[0106] The first step is to melt the TiZrNb alloy ingot. First, Ti, Zr, and Nb with high melting points are smelted into TiZrNb melt; the power of the arc melting furnace is turned off, and the TiZrNb melt is cooled and solidified to form a TiZrNb alloy ingot. Tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com