Macromolecule water reducing agent for reducing viscosity of clay slurry as well as preparation method and application thereof

A polymer and water-reducing agent technology, applied in the field of polymer water-reducing agents, can solve the problems that organic polymer water-reducing agents have not been industrialized, and inorganic water-reducing agents cannot achieve low dosage and high water-reducing rate. , to achieve the effect of good water reduction effect, small dose and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

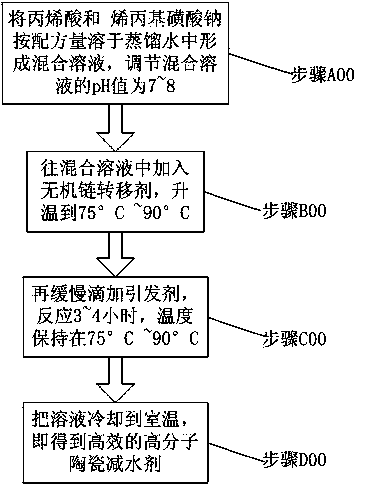

[0027] like figure 1 Shown is a flow chart of the steps of the preparation method of the polymer water reducer for reducing the viscosity of clay slurry in the present invention. A method for preparing a polymer water reducer for reducing the viscosity of clay slurry as described above, specifically comprising the following steps:

[0028] Step A00: dissolving acrylic acid and sodium allyl sulfonate in distilled water according to the formula to form a mixed solution, and adjusting the pH value of the mixed solution to 7-8;

[0029] Step B00: Add an inorganic chain transfer agent to the mixed solution, and heat up to 75 ° C ~ 90 ° C;

[0030] Step C00: Slowly add the initiator dropwise, react for 3 to 4 hours, and keep the temperature at 75°C to 90°C;

[0031] Step D00: Cool the solution to room temperature to obtain a high-efficiency polymer ceramic water reducer.

[0032] In this embodiment, in the step A00, adjusting the pH value of the mixed solution to 7-8 is realized ...

Embodiment 1

[0036] Step A00: Add 120g of acrylic acid, 40g of sodium allyl sulfonate and 200g of distilled water to a three-necked flask with a stirrer, stir to form a mixed solution, and dropwise add a mass fraction of 60% sodium hydroxide solution to adjust the mixed solution The pH value is 8; step B00: add inorganic chain transfer agent sodium bisulfite 8g in mixed solution, be warming up to 80 DEG C; Step C00: slowly add initiator ammonium persulfate 9.6g again, react 4 hours, temperature Keep it at 80°C; Step D00: Cool the solution to room temperature to obtain a high-efficiency polymer ceramic water reducer.

[0037] The performance test of the polymer ceramic water reducer prepared above was carried out: the test results showed that when the polymer ceramic water reducer prepared above accounted for 0.25% of the mass fraction of clay, the viscosity of the slurry system was 771mPa·s , the initial flow time is 50s, the fluidity is good, there is no sedimentation phenomenon after bei...

Embodiment 2

[0039] Step A00: Add 100 g of acrylic acid, 25 g of sodium allyl sulfonate and 100 g of distilled water into a three-necked flask with a stirrer, stir to form a mixed solution, and add dropwise a 60% sodium hydroxide solution to adjust the mixed solution The pH value is 8; Step B00: add inorganic chain transfer agent sodium bisulfite 8.8gg in mixed solution, be warming up to 85 DEG C; Step C00: slowly add initiator ammonium persulfate 5g again, react 5 hours, temperature Keep it at 85°C; Step D00: Cool the solution to room temperature to obtain a high-efficiency polymer ceramic water reducer.

[0040] The polymer ceramic water reducer prepared above was tested for performance: the test results showed that when the polymer ceramic water reducer prepared above accounted for 0.25% of the mass fraction of clay, the viscosity of the slurry system was 826mPa·s , the initial flow time is 60s, the fluidity is good, there is no sedimentation phenomenon after being left overnight, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com