Production device system and production process for polymethoxy dimethyl ether (PODE)

A polymethoxydimethyl ether, production device technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problem that formaldehyde is difficult to separate, economic feasibility is not advantageous, catalysts and trioxymethylene prices. expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

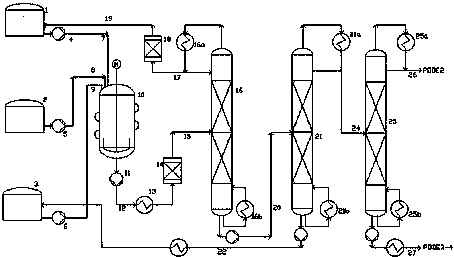

[0059] First drop into 600 kilograms of macroporous strong acid resins, 2700 kilograms of paraformaldehydes in reactor 10, pump 3700 kilograms of methylals into reactor 10 from methylal storage tank 2 with pump 5;

[0060] Start the reactor stirrer to fully mix the catalyst and the reaction materials, pass heating steam or heat transfer oil into the jacket of the reactor, slowly heat the reactor to 150°C and keep the temperature for 6 hours, the reaction reaches equilibrium, stop heating, and take samples to analyze the reaction Product composition, the results are shown in Table 1 (expressed in weight percent).

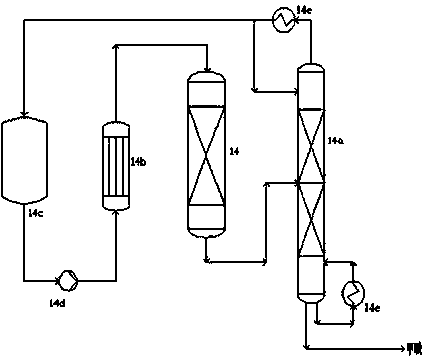

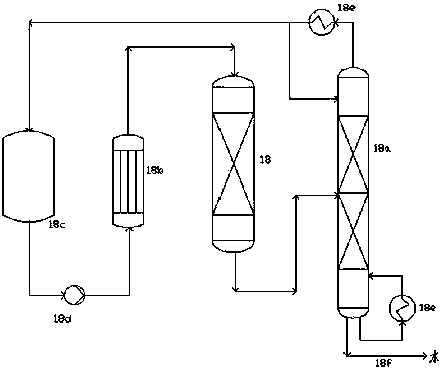

[0061] Use the pump 11 to pump the reaction product into the cooler 13 through the pipeline 12 to lower the temperature of the material to 40 ° C, then enter the first rectification tower 16 after entering the deacidification adsorber 14 to remove formic acid; the deacidification adsorber is equipped with 500 kg load type Solid alkali, the superficial velocity of the...

Embodiment 2

[0068] First drop into 600 kilograms of solid superacids, 1200 kilograms of paraformaldehyde in reactor 10, pump 3900 kilograms of light components by pump 4 through pipeline 7 from light component storage tank, pass pipeline 9 by pump 6 from heavy component storage tank Pump 1200 kilograms of heavy components, technological process is as example 1, and final result is shown in Table 2.

[0069] Table 2 Weight percentage and total amount of related logistics

[0070]

[0071] In Example 2, the reaction mass gross weight: 1200+3900+1200=6300 kilograms, wherein PODE 5-8 The content is: 1200÷6300=19%. As can be seen from stream 12 in table 2, PODE in the reaction product 5-8 The content is only 3.82%, indicating that most of the heavy component PODE 5-8 It can be completely converted into the target product PODE by re-reaction 3-4 ;

[0072] Comparing Table 1 and Table 2, target product PODE3-4 is 12.29+6.36%=18.65% in example 1, target product PODE in example 2 3-4 Be 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com