A kind of interface modified carbon fiber/resin matrix composite material and preparation method thereof

A composite material and carbon fiber technology, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of low fiber surface grafting rate, decreased carbon fiber bulk performance, affecting the overall performance of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

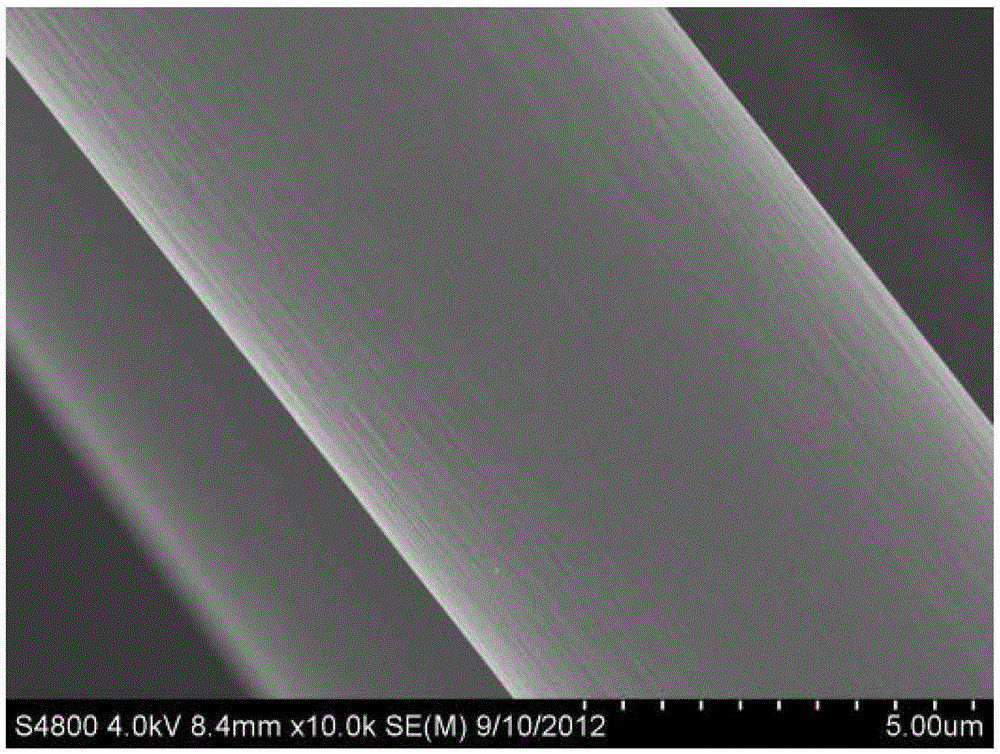

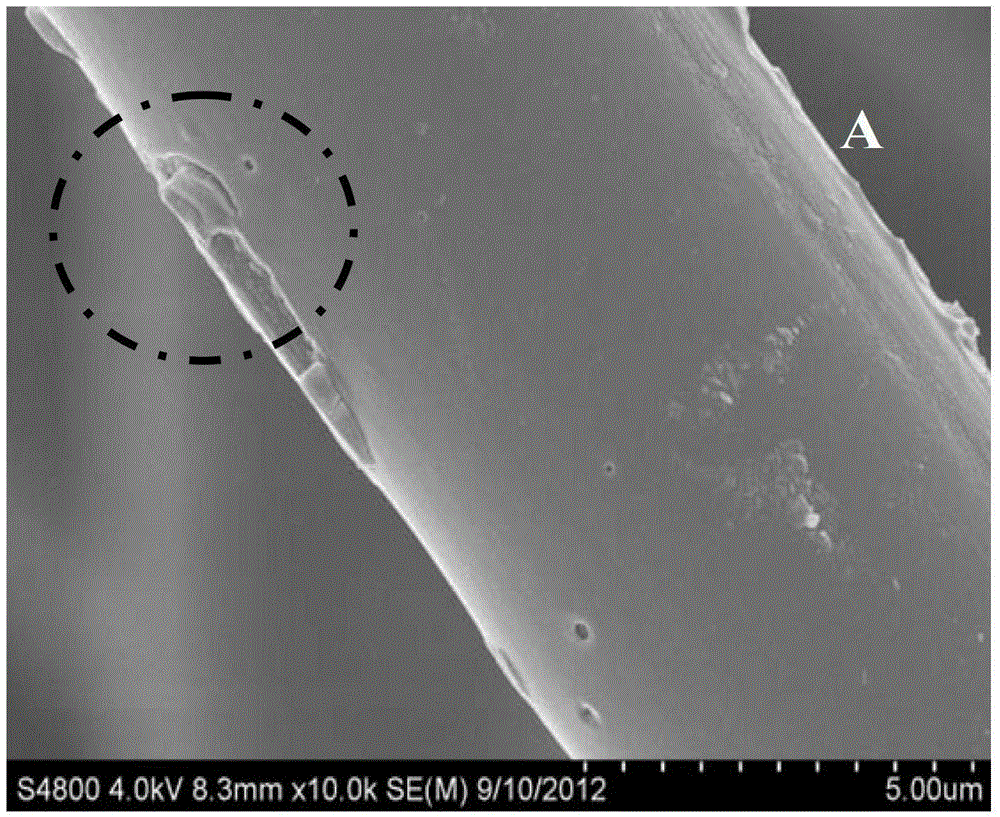

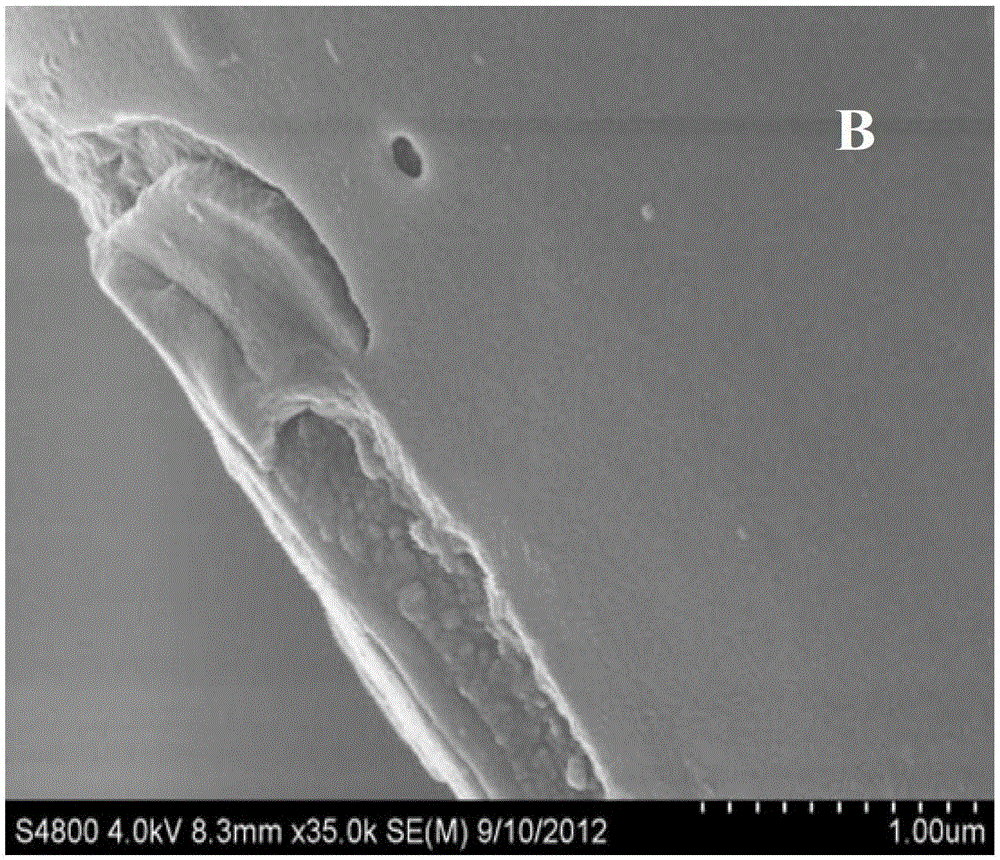

Image

Examples

preparation example Construction

[0101] Fabrication of interfacially reinforced composites

[0102] The above-mentioned method is used to prepare interface-reinforced and modified carbon fibers, and then the carbon fibers are fixed on the substrate and shaped through a composite material forming process to obtain the composite material.

[0103] The forming process of the interface reinforced composite material of the present invention is not limited, and the available forming processes include (but not limited to): vacuum assisted resin injection molding process, resin film infiltration molding process, autoclave forming process and compression molding process. Preferably, the forming process of the present invention is an autoclave forming process.

[0104] In a preferred example of the present invention, the steps of the composite material forming process are as follows:

[0105] The modified carbon fiber bundles are arranged and fixed in one direction, impregnated with a resin solution, and the solvent i...

Embodiment 1

[0118] Step (1) Oxidation treatment of carbon fiber precursors: add 1 part by weight of carbon fiber to 100 parts by weight of 98% sulfuric acid, then reflux at a temperature of 100°C for 2 hours, take out the carbon fiber and wash it with deionized water until the washing liquid is neutral , and dried at a temperature of 60°C to obtain surface oxidized carbon fibers;

[0119] Step (2) prepares the carbon fiber that surface is connected with hexachlorocyclotriphosphazene: acid-binding agent and carbon oxide fiber are put into anhydrous tetrahydrofuran according to 15:100 weight ratio, then the hexachlorocyclotriphosphazene of 5 parts by weight is dissolved Slowly add the above reaction solution into the solvent, react at 30°C for 24 hours, take out the carbon fiber and wash it with solvent for several times, and dry it in a vacuum oven at 60°C for later use.

[0120] Step (3) Grafting polyphosphazene on the surface of carbon fiber: put 100 parts by weight of carbon fibers graf...

Embodiment 2

[0123] Step (1) Oxidation treatment of carbon fiber precursor (unsizing): put 10 parts by weight of carbon fiber into 100 parts by weight of 60% nitric acid, then reflux at a temperature of 60°C for 2 hours, then filter and wash with deionized water until The washing solution is neutral, and the surface oxidized carbon fibers are obtained by drying at a temperature of 80°C.

[0124] Step (2) prepares the carbon fiber that the surface is connected with hexachlorocyclotriphosphazene: acid-binding agent and carbon oxide fiber are put into anhydrous tetrahydrofuran according to the weight ratio of 40:100, then the hexachlorocyclotriphosphazene of 15 parts by weight is dissolved Slowly add the above reaction solution into the solvent, react at 30°C for 12 hours, take out the carbon fiber and wash it with solvent for several times, and dry it in a vacuum oven at 60°C for later use.

[0125] Step (3) Grafting polyphosphazene on the surface of carbon fibers: putting 100 parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com