A polyvinylidene fluoride/palladium nanoparticle hybrid hollow fiber membrane and its preparation method

A technology of polyvinylidene fluoride and palladium nanometers, which is applied in the manufacture of hollow filaments, chemical instruments and methods, and chemical characteristics of fibers, can solve problems such as the decline in catalytic activity, and achieve simple equipment, easy industrial implementation, hydrophilicity and The effect of improving the anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of PVDF solution: PVDF is dissolved in DMF to obtain a 15Wt% polyvinylidene fluoride solution;

[0047] (2) Preparation of polymer gel: dissolve 50 g of polymer monomer (meth)acrylic acid or 4-vinylpyridine, 0.5 g of crosslinking agent MBAA and 0.5 g of initiator KPS in 1000 mL of water, and heat 1. Carry out radical polymerization for 8 hours under nitrogen protection conditions, centrifugal precipitation, and vacuum drying to obtain poly(meth)acrylic acid or poly-4-vinylpyridine gel;

[0048] (3) Preparation of polymer gel / palladium nanoparticle hybrids: at 25°C, 20 g of the polymer gel obtained in step (2) was dispersed in 100 mL of deionized water, 1 g of chloropalladium acid was added, and 1 g of sodium borohydride Reduction, centrifugal precipitation, and drying to obtain polymer gel / palladium nanoparticle hybrids;

[0049] (4) Preparation of polymer gel / palladium nanoparticle hybrid dispersion: disperse the polymer gel / palladium nanoparticle hybr...

Embodiment 2

[0056] (1) with embodiment 1;

[0057] (2) with embodiment 1;

[0058] (3) with embodiment 1;

[0059] (4) with embodiment 1;

[0060] (5) with embodiment 1

[0061] (6) Preparation of spinning solution: the polyvinylidene fluoride solution obtained in step (1), the polymer gel / palladium nanoparticle hybrid dispersion obtained in step (4) and the pore-forming agent solution obtained in step (5) Mix according to mass ratio 80:20:0, dissolve, degas, obtain 15wt% spinning solution;

[0062] (7) with embodiment 1;

[0063] (8) with embodiment 1;

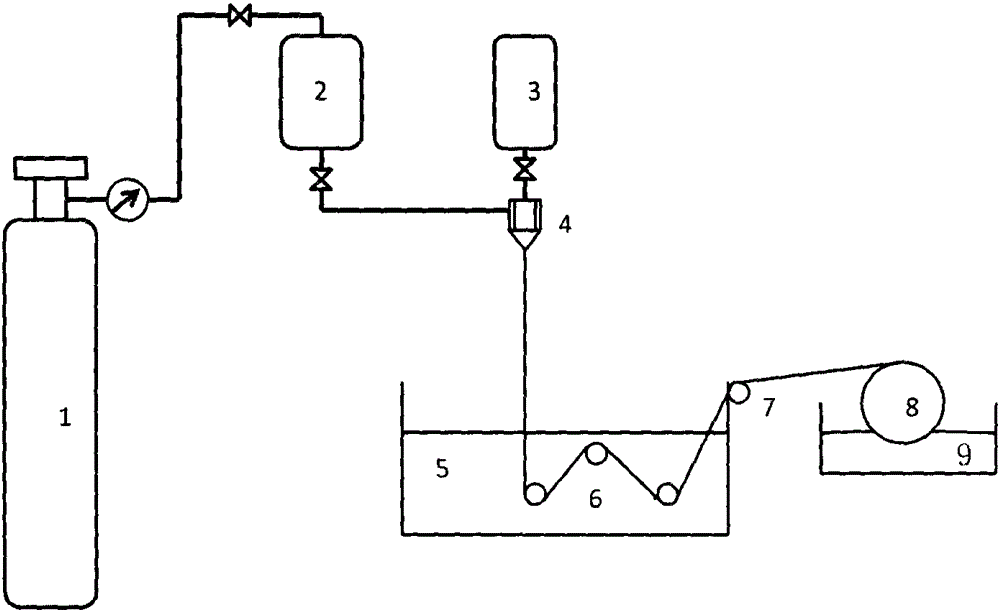

[0064] (9) Hybrid membrane preparation: adopt dry-wet spinning method, use hollow fiber spinning machine ( figure 1 ) and the core liquid prepared by the above step (7) and the coagulation bath prepared by the above step (8), in a dry spinning length of 10 cm, the temperature of the spinning solution is 50 ° C, and the temperature of the core liquid and the coagulation bath is 30 ° C. (6) The obtained spinning solution is spun to ...

Embodiment 3

[0066] (1) with embodiment 1;

[0067] (2) with embodiment 1;

[0068] (3) with embodiment 1;

[0069] (4) with embodiment 1;

[0070] (5) with embodiment 1;

[0071] (6) Preparation of spinning solution: the polyvinylidene fluoride solution obtained in step (1), the polymer gel / palladium nanoparticle hybrid dispersion obtained in step (4) and the pore-forming agent solution obtained in step (5) Mix according to mass ratio 60:40:0, dissolve, degas, obtain 15wt% spinning solution;

[0072] (7) with embodiment 1;

[0073] (8) with embodiment 1;

[0074] (9) Hybrid membrane preparation: adopt dry-wet spinning method, use hollow fiber spinning machine ( figure 1 ) and the core liquid prepared by the above step (7) and the coagulation bath prepared by the above step (8), at a dry spinning length of 25 cm, a temperature of the spinning solution of 50 ° C, and a temperature of the core liquid and the coagulation bath of 30 ° C, the above steps (6) The obtained spinning solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com