Supported two-dimensional layered molybdenum sulfide composite material and preparation method and application thereof

A two-dimensional layered and composite material technology, which is applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, chemical instruments and methods, etc., can solve the problems of negative impact on catalytic activity, reduced catalyst activity, high economic cost, etc., to avoid catalyst Effects of poisoning, avoiding reduction in catalytic activity, and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

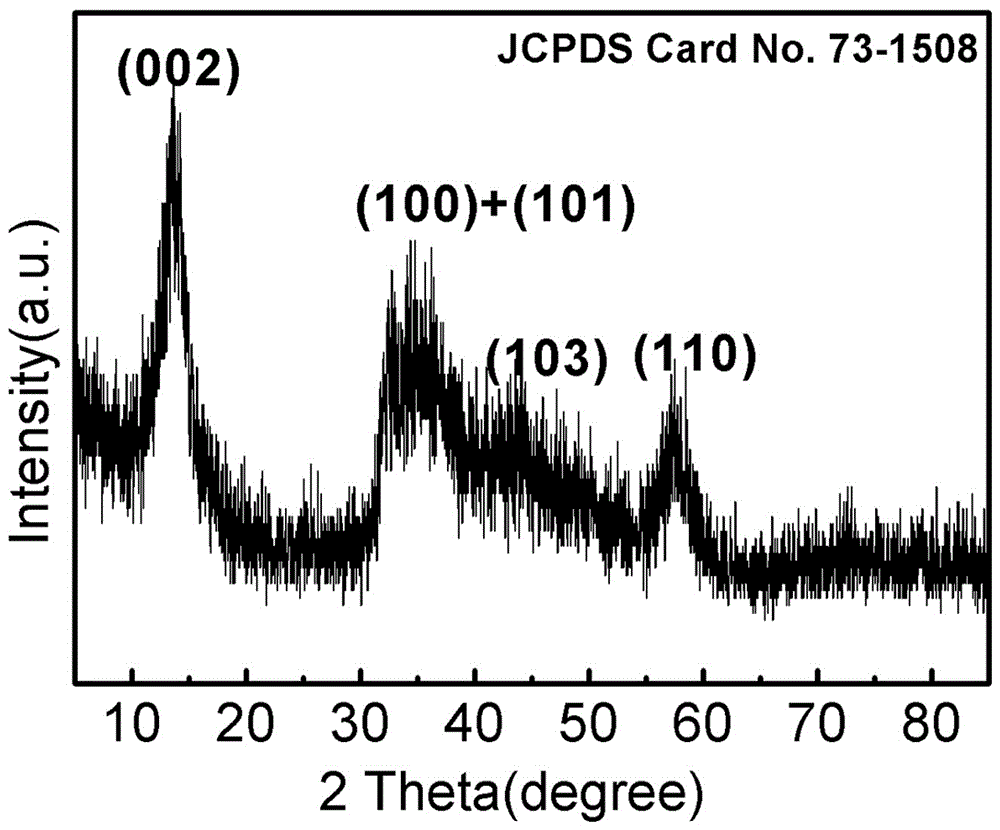

[0031] 1) Dissolve 1mmol of ammonium molybdate in 35ml of deionized water and stir for 5min until all is dissolved to form a uniform and transparent solution A.

[0032] 2) Add 30mmol of thiourea to solution A, and stir for 30min to mix uniformly to form a uniform light blue solution B.

[0033] 3) Transfer the above-mentioned solution B to a 50mL polytetrafluoroethylene lined reaction kettle, raise the temperature to 220°C, the constant temperature time is 24h, and then naturally cool to room temperature.

[0034] 4) After centrifugal separation at 9000 r / min for 15 minutes, the obtained black mixed liquid is washed three times with distilled water and absolute ethanol, and the obtained black product is dried at 80° C. to obtain the ultra-thin molybdenum sulfide nanosheet material.

Embodiment 2

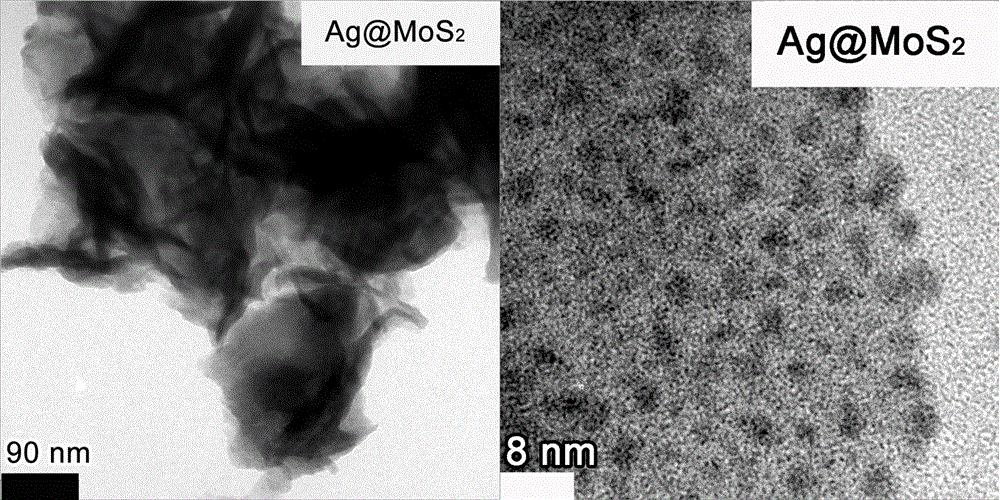

[0036] 1) Using the ultra-thin molybdenum sulfide nanosheets obtained in Example 1 as a carrier template, add 95 mg of the ultra-thin molybdenum sulfide nanosheets to a mixed solution of 20 mL of deionized water and absolute ethanol, where deionized water and The volume ratio of water to ethanol is 1:1, and then 1 mL of 5 mg / L nitric acid solution is added, the above-mentioned mixed liquid is sonicated for 30 minutes, and then stirred in a dark room for 30 minutes to form a uniformly mixed suspension A.

[0037] 2) Transfer the above-mentioned suspension liquid A to the quartz test tube of the photochemical reactor, and under the condition of stirring, use a mercury lamp with a power of 500W to irradiate with ultraviolet light for 4h to reduce to obtain a black mixed liquid B.

[0038] 3) After the obtained black mixed liquid product B is centrifuged at 9000r / min for 15min, it is washed three times with deionized water and absolute ethanol, and the obtained black product is dried at...

Embodiment 3

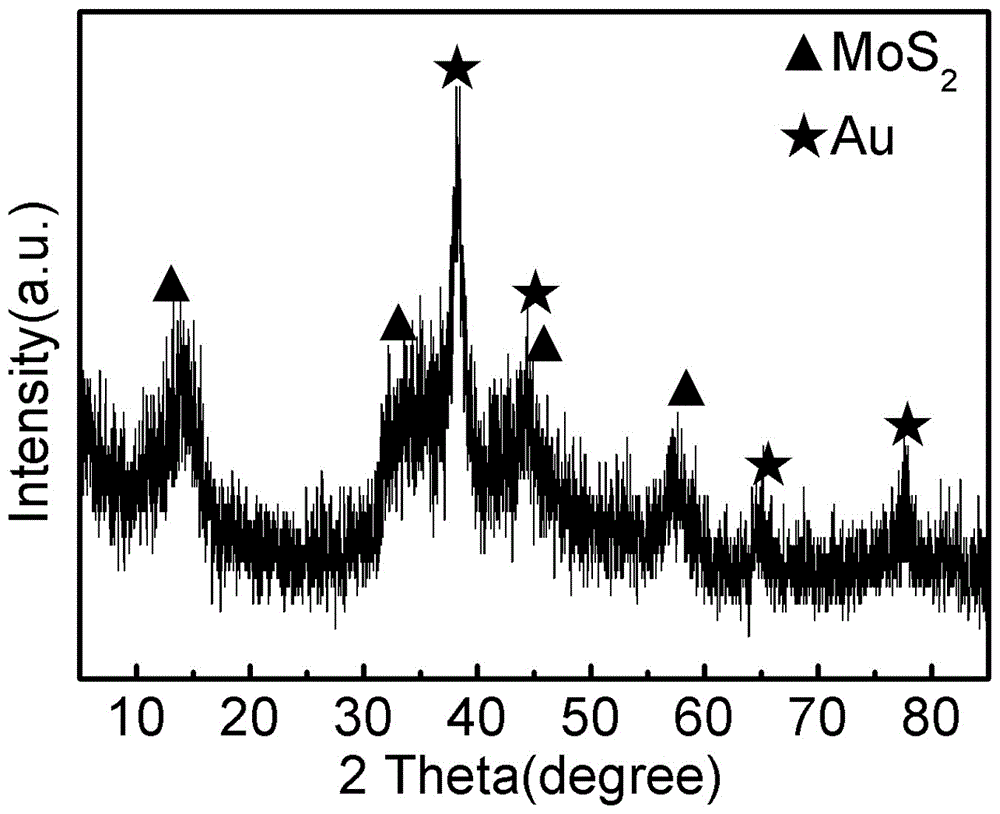

[0044] 1) Using the ultra-thin molybdenum sulfide nanosheets obtained in Example 1 as a carrier template, add 95 mg of the ultra-thin molybdenum sulfide nanosheets to 20 mL of a mixed solution of deionized water and ethanol, where the volume of deionized water and ethanol The ratio is 1:1, and then 1 mL of 5 mg / L sodium chloroaurate solution is added, the above-mentioned mixed liquid is sonicated for 30 minutes, and then stirred in a dark room for 30 minutes to form a uniformly mixed suspension A.

[0045] 2) Transfer the above-mentioned suspension liquid A to the quartz test tube of the photochemical reactor, and under the condition of stirring, use a mercury lamp with a power of 500W to irradiate with ultraviolet light for 4h to reduce to obtain a black mixed liquid B. 3) After centrifugation at 9000r / min for 15 minutes, the mixture product obtained above is washed three times with distilled water and absolute ethanol, and the resulting black product is dried at 80℃ to obtain Au...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com