Preparation method for SnO2-based composite visible light photocatalyst

A photocatalyst and visible light technology, which is used in the preparation of new nanomaterials and composite photocatalysts, can solve the problems that photocatalysts cannot achieve visible light photocatalysis, and achieve stable photocatalytic performance, tight integration, and easy large-scale industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. SnS 2 Preparation of powder:

[0015] 3.506 g of crystalline tin tetrachloride (SnCl 4 ·5H 2 O) and 1.5026 g of thioacetamide were added to 38 ml of deionized water, stirred with a magnet, and at the same time, 2 ml of glacial acetic acid was added to the solution, and stirred for 6 hours until the solution appeared light yellow. The stirred mixed solution was added into a polytetrafluoroethylene high-pressure reactor, and reacted at 120° C. for 12 hours. Naturally cool to room temperature to obtain the solids produced by the reaction, then wash with deionized water, centrifuge, and dry at 70°C to obtain SnS 2 powder sample.

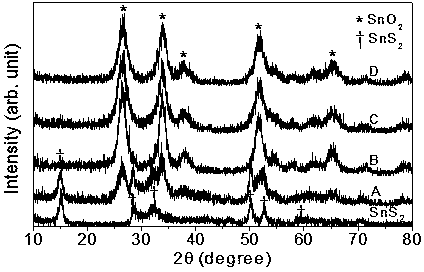

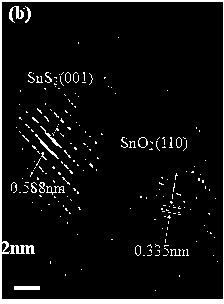

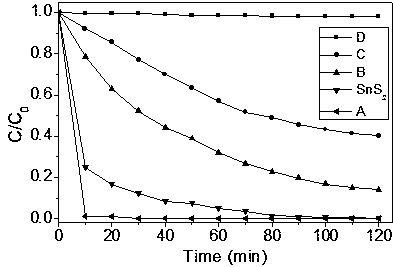

[0016] 2. SnO 2 / SnS 2 Preparation of Composite Nanostructures:

[0017] Dilute 30% H2O2 to 0.3%, 1.5%, 3% and 6% respectively with deionized water, and set aside.

[0018] Weigh 0.4 g of SnS 2 powder, add it to 38 ml deionized water, add a magnet to stir, and add 2 ml of different concentrations of H while stirring 2 o 2 solution, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com