Method for using additive for producing macrocrystalline fused magnesite

A technology of fused magnesia and additives, applied in the direction of magnesia, etc., can solve the problems of decreased Ca/Si ratio, unachieved, complicated process, etc., and achieve the effect of improving electrical conductivity and easy arc starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

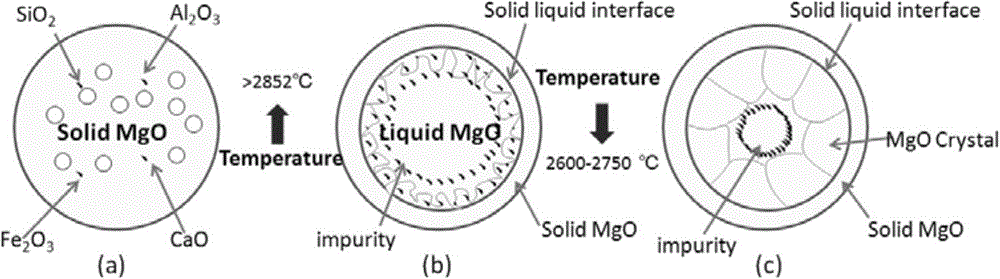

Method used

Image

Examples

Embodiment 1

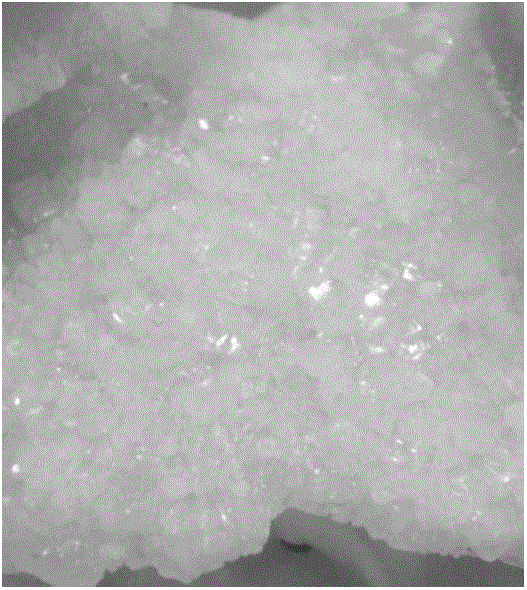

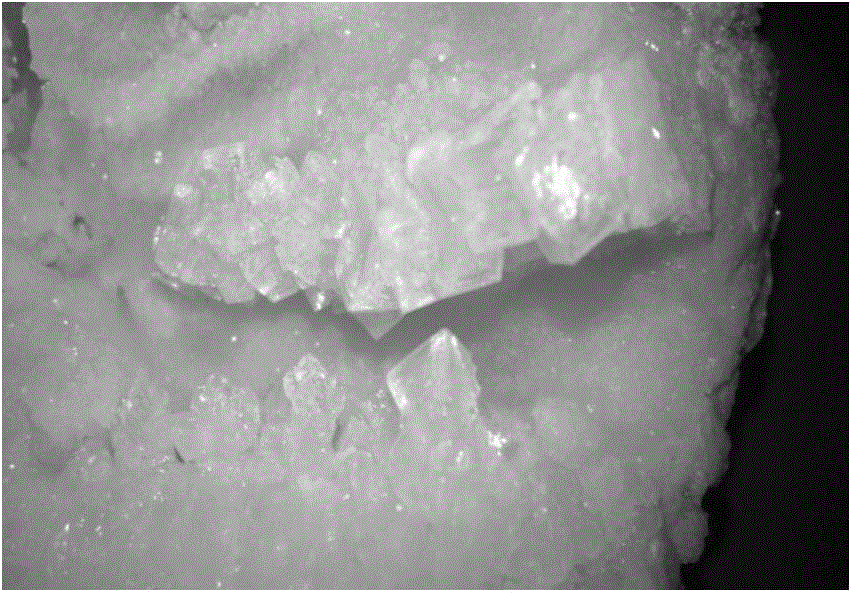

[0036] Take 23.1kg of light-burned magnesia with a purity of 85%, and a particle size of 200 mesh. First, 220g of high-purity graphite powder and raw materials are uniformly mixed with a ball mill. In addition, 45g of zirconia was sprinkled in layers. The stockpile was then compacted with weights for 27 hours. A three-phase electric arc furnace with a power of 35KVA is used for melting, and 10g of samarium oxide and 10g of yttrium oxide are added at the time of the first feeding. Melting time is 8.5 hours, during which voltage is 50-100V, and electric current is 200-380A. Finally, high-purity white and transparent large-crystal fused magnesia is obtained, and the magnesium oxide content is above 99.30%. Such as diagram 2-1 , Figure 2-2 Shown:

[0037]

Embodiment 2

[0039] Get 17.2kg purity to be 85% lightly burned magnesia, particle size 200 orders. First, 230g of high-purity graphite powder and raw materials are uniformly mixed with a ball mill. In addition, 65g of zirconia was sprinkled in layers. The stockpile was then compacted with weights for 24 hours. A three-phase electric arc furnace with a power of 30KVA is used for smelting, and 15g of samarium oxide and 5g of yttrium oxide are added in the first feeding. The melting time is 6.5 hours, during which the voltage is 60-80V and the current is 100-350A. As shown in the figure below: Finally, high-purity white and transparent large-crystal fused magnesia is obtained, and the magnesium oxide content is above 99.40%. Five samples were obtained for ICP-AES detection, and the measured results are as follows:

[0040]

Embodiment 3

[0042] Get 15.8kg purity to be 85% lightly burned magnesia, particle size 200 orders. First, 210g of high-purity graphite powder and raw materials are uniformly mixed with a ball mill. In addition, 70g of zirconia was sprinkled in layers. The stockpile was then compacted with weights for 30 hours. A three-phase electric arc furnace with a power of 30KVA is used for smelting, and 5g of samarium oxide and 15g of yttrium oxide are added in the first feeding. The melting time is 10 hours, during which the voltage is 60-80V and the current is 100-320A. As shown in the figure below: Finally, high-purity white and transparent large-crystal fused magnesia is obtained, and the magnesium oxide content is above 99.50%. Three samples were obtained for ICP-AES detection, and the measured results are as follows:

[0043]

[0044]The additives of the present invention all use cheap oxides to replace expensive rare earth alloy materials. The main components are high-purity graphite pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com