Method for processing viscose fiber production wastewater

A viscose fiber and waste water production technology, which is applied in textile industry waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing the load of sedimentation tanks, resource loss and waste, and large footprint and other issues, to achieve the effect of reducing fixed investment, reducing production cost, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation process of the present invention will be further described below in conjunction with the embodiments.

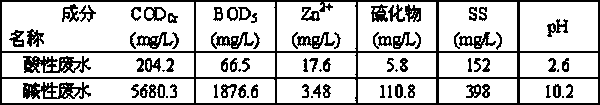

[0027] Get viscose fiber production waste water, its water quality situation is as follows:

[0028] Water Quality Components of Viscose Fiber Production Wastewater

[0029]

[0030] Follow the steps below to implement:

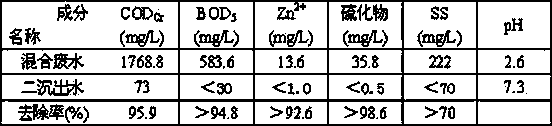

[0031] 1. The acidic and alkaline wastewater produced in the production of viscose fiber in the stripping reaction process is mixed at a ratio of 1:2.5 to pH=2.9. The mixed wastewater enters the stripping reaction tank, and a large amount of suspended viscose is precipitated by the acid Cellulose, mostly H 2 S, CS 2 Other components can also be blown off to remove.

[0032] 2. Shallow air flotation process: The raw water treated by the stripping reaction process enters the water from the rotating water inlet pipe in the center of the air flotation tank, and distributes water through the rotating water distribution p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com